The DoorHan company has been producing gates, automation, modular structures, roller shutters for 20 years, and sells goods in 30 countries. The manufacturer's factories are located in the CIS countries, the Czech Republic, China. Owners of houses and plots prefer the installation of Dorhan gates, since the products are of high quality and reliability. Installation is easy, the assembly technology is developed to the smallest detail.

- Design features of the Dorhan gate

- Varieties of gates

- Sectional

- Recoil

- Foldable

- Flexible

- How to install yourself

- Preparatory work

- Installing the frame

- Assembly and installation of panels

- Mounting the torsion mechanism

- How to set up a mechanism

- Sectional door adjustment

- How to adjust the drive, adjust the springs

Design features of the Dorhan gate

The basic elements of the gate are designed in such a way that during any period of operation you can buy and install additional parts to increase comfort.

Advantages of Dorhan technology:

- resistance to bad weather;

- safety, durability;

- the ability to choose the type of opening and type of gate.

The speed of installing Dorhan gates depends on the experience of the installer; for the work you will need tools that are always at hand.

The products are accompanied by a certificate of European and domestic standards. All spare parts, drives and automatics are supplied by the manufacturer.

Varieties of gates

The designs differ depending on the opening, sizes and types of canvases.

The initial complete set includes devices and parts:

- door leaf with rubber gaskets, it can be simple and insulated, moves on hinges, rollers;

- upper beam for direction of movement;

- bottom beam, the element may be absent for some types of opening;

- handles, latches, crossbar locks;

- brush seals;

- automation.

There are sectional types, folding gates, folding and flexible designs. Simple and torsion springs can withstand 25 thousand opening cycles; cable break protection mechanisms are provided.

Sectional

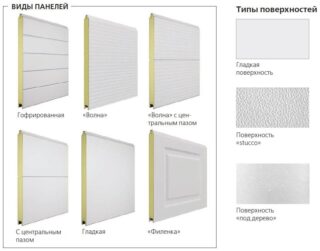

The canvas moves along the guide profiles attached to the edges of the opening. The doors are made of sandwich panels with a thickness of 40 - 60 mm. The slabs are filled with polyurethane foam, which is framed on both sides with painted steel sheets.

When opening, the segments of the garage door alternately move to the ceiling, thus saving space in front of the opening, you can drive close to the gate. The leaf moves smoothly, quietly thanks to chain and shaft drives. You can control it from a stationary or portable remote control, a mobile phone. The canvas is opened completely or fixed halfway through the span.

Recoil

Sliding structures are reliable, their mechanisms can withstand 50 thousand opening cycles. Photocells on opposite sides record the presence of people and objects in the gate span. Roller carts are located inside the guide beam, so there is no need to clean debris and snow.

Foldable

Such canvases are installed in places with limited space on the sides and on top, tunnel structures are represented by separate segments built into the fences.Assembly instructions for sectional doors that fold down allow installation in garage openings with a height of 1.5 - 2.5 m, a width of 1.5 - 2.5 m. There are types of gates, the swing leaves of which fold to the side.

For sequential fastening and folding of the segments, bearing hinges are used. For work, frames or cantilever beams are needed; in another version, small structures can work without additional parts.

Flexible

The surface of PVC cloths is moisture resistant, environmentally friendly for people; translucent and transparent materials are used for manufacturing. They are used to keep warm inside the garage, warehouse.

Functions of flexible canvases:

- isolate separate areas of space;

- protect from drafts;

- reduce the strength of sound waves;

- protect from dust, wind.

The sash plane is self-healing under its own weight after the passage of the car or the passage of people. They are carried out in the form of separately hanging strips or they make a swing version of the sashes in the frame, which, after opening, return to their original position.

How to install yourself

After the preparatory work, the frame is initially mounted, then the panels are assembled from the panels and installed in the opening. After that, the torsion mechanism is assembled and attached.

They take tools for work:

- an electric drill with a set of drills of different diameters and attachments for screwing hardware;

- a knob with a set of nozzles;

- a set of wrenches, pliers, hammer;

- grinder;

- measuring tool, level, plumb line.

The installation instructions for Dorhan sectional doors provide for a working setting after installation. The process includes adjustment of the electric drive, adjustment of the spring mechanism.

Preparatory work

Before you install the Dorhan gate with your own hands, prepare the opening. Foreign objects, debris are removed on the surface under the frame and in the area of opening the sash, the plane must be flat. The lower part is planned, if it is soil, a screed is made. The old lining of the driveway is removed or repaired.

A foundation is made for the lower girders for the rollers, for which they dig a trench. At the bottom, sand and crushed stone is added, then reinforcing bars are placed. The base is concreted into the installed wooden formwork, the mass is butt-faced with a shovel or reinforcement for distilling bubbles.

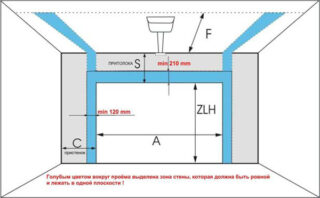

Installing the frame

Unpack and lay out the parts, study the step-by-step installation guide. In the opening, the position of the vertical flaps is marked so that the gap from the end to the guides is no more than 30 mm. The lower element of the canvas is positioned so that the sides are evenly aligned with the edges of the opening. Check horizontality and verticality.

On the profiles, they mark the place of fixing the sash, make holes for the dowels, install the supporting elements on both sides of the span. Horizontal purlins are fastened using corners on bolts with nuts, they are connected to vertical parts.

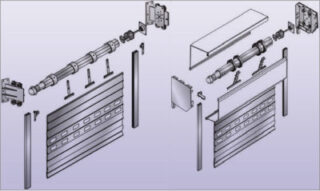

Assembly and installation of panels

Holes are provided in the body of the panels, which simplifies assembly. The bottom plate is placed on self-tapping screws, which are screwed into corner fasteners and hinges. The bracket is fixed for 5 - 7 hardware, two are enough for the hinges. Hinges and holders are placed on the middle segment. Attention is paid to the upper plate, since the corner fasteners and roller bearings will be mounted here.

The fixation of the brush strip is also planned at the top. High-quality fasteners will prevent segments from breaking. Gradually, the frame is filled with panels so that there are no gaps between them, as well as between the upper segment and the lintel.

Mounting the torsion mechanism

The device is installed in brackets at the ends, then the bearing is put on the axle, and a spring made up of two parts is placed there.Holes are drilled in the side of the drum for mounting the cable, the ends are passed through the holes, and the cable itself is wound on the drum body, fastened with a bolt connection.

Loops are made on the tails of the cable, they are placed in the bracket pocket, fixed with brackets, then the tension is adjusted. The springs are regularly checked, the cables are inspected so that they do not break and do not jam.

The springs are protected in a spiral-in-spiral manner, and the torsion devices are protected by a ratchet clutch.

How to set up a mechanism

Adjustment errors will lead to increased stress on the structure, cable breakage and breakage.

When setting up, pay attention to the following points:

- tightness and exact fit of parts into the intended sockets, conformity of joints, precision of joints;

- correct assembly according to the technological map from the technical passport.

If the mechanism does not work properly, the web does not close completely or is skewed in relation to the frame. They regulate the action of the mechanism so that no harsh sounds are heard, and the cable does not get tangled or fly off.

Sectional door adjustment

To tension the chain, check the reliability of fixing the brackets on the support, fastening the drum with a set screw. The shaft is turned until the cable stops sagging. The axis is turned slowly and smoothly so that it can be stopped at any time.

The springs are wound 2 - 3 turns, no longer required. The spirals are fixed by tightening the bolt lugs. Coordinating the cables is easy, any installer can handle the job. If the adjustment fails, call a specialist - a representative of the company.

How to adjust the drive, adjust the springs

Attention is paid to the operation of the drive if the gate opens manually well, and malfunctions occur during the action of the automation. To correct the gate, put it in the middle position, turn off the power supply. Press the drive button, hold it, turn on the power - the light should blink several times. The button is pressed several times, after which the gate should begin to move and stop at the end position.

The spring is adjusted if the web is difficult to open automatically and manually. To coordinate the untwisted spiral, unscrew the latches, turn it several turns, trying not to overtighten. A broken or deformed spring must be replaced.