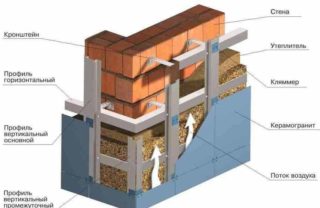

Ventilated facade - facing material, which is a whole structure of a metal frame, insulation and finishing layer. Fasten it so that an air gap remains between the product and the base, through which moisture and condensation are eliminated. Due to the versatility of the elements, it is possible to arrange complex structures. Installation of ventilated facades can be done by hand.

Preparation of technical documentation

According to the building rules, as well as the decree of the Government of the Russian Federation No. 1636 dated December 27, 1997, all structures and technologies must have a confirmed suitability in the territory of the country. This requirement applies to ventilated facades. Any structure of this type must have the Technical Certificate of the State Construction Committee. Installation of the product is carried out in the presence of the following documents:

- conclusion on the assignment of a fire hazard class and on seismic resistance;

- paper confirming the bearing capacity of the system;

- a conclusion on corrosion resistance (the document indicates the service life of the product when it is used in different environments).

Also, a separate set of papers is required for a specific object. It includes a heat engineering calculation, determination of the static load of the system, a facade design, a technological map for hinged ventilated facades, an estimate for the work carried out, as well as a design for the production of works.

Necessary tools for the job

- Measuring instruments: building level, laser level. With their help, the accuracy of the facade dimensions is determined, the markings for the fasteners are applied, the guide elements are aligned in the horizontal and vertical planes.

- Perforator. With its help, holes are made for installing fasteners.

- Tool for screwing anchor bolts into the base.

- Drill or screwdriver.

- Manual, electric or pneumatic riveter for fixing a metal profile to a bracket, assembling cladding panels.

- Grinder, cut-off saw, milling machine, listogib.

- Clamps for pre-assembly of the guide elements before screwing them on.

If galvanized steel is used in the work, metal scissors are required for cutting it.

Features of installation of ventilated facades

Installation of metal structures and fasteners

Before installing the structure, beacons are installed on the outer surface of the wall. Brackets and profile elements will be fixed according to the marking. The axial distance between the L-shaped fasteners vertically is 50-100 cm, depending on the type of facing plates. The horizontal distance is determined by the project and the size of the facade finish.

When installing profiles, do not forget about the thickness of the seam.Correctly selected fasteners will allow you to align the profile in relation to the plane of the base. Thermal spacers are required to install the brackets. They are fixed with corrosion-resistant anchors. If the basis is brickwork, it is not recommended to mount the dowels into the seams. The distance from the joint to the anchor ranges from 2.5 to 6 cm.

Additionally, brackets with plates for mounting ebbs and window slopes are fixed on the wall.

If heavy slabs are used for facade cladding, the number of profile attachment points is increased. For the installation of lightweight materials, vertical rails are sufficient.

Insulation installation

When installing the facade of the building, the insulation is fixed from the bottom up from the left side of the wall. The first row is fixed on the starting profile. If the heat insulator slabs are installed in 2 layers, the dressing of the seams is mandatory - they should not coincide. They need to be laid as tightly as possible so that voids do not form.

For fixation, plastic disc-type dowels are used. They are equipped with spacer rods. If the walls are even, it is allowed to glue the material. When using a moisture-proof film in operation, the heat insulator is nailed to the base with two dowels. After its installation, the rest of the fasteners provided by the project are installed. The film is laid with an overlap. In total, 5 dowels are installed on each plate. A hole is preliminarily prepared for each fastener. Basalt wool is considered the best option for an insulator.

Securing cladding materials

A supporting profile is used to fasten the ventilated facade. It is fixed to the brackets with front rivets. When installing each element, a building level, a theodolite, and a plumb line are used. There should be a gap of 3-5 cm between the base and the cladding. Air should circulate freely inside.

Installation is carried out:

- For kleimers. They are made of stainless steel. They are attached to the guides with rivets. The slabs are inserted from the side into clamps that are located outside the cladding material. The fixings are painted in the same color as the finish. For additional fixing of the plates, a self-adhesive strip is used, which acts as a shock absorber, as well as a heat insulator.

- With the help of rust. It is a side channel, which is installed horizontally on the guides. Fasten it with a self-tapping screw. The plate is simply put into the shelf of the lower profile and clamped with the upper one.

- We glue. The cladding boards are fixed with a highly effective substance.

Another way to mount the material is to install it using hooks. If you use special corners, you can get the job done faster. However, this method can slightly worsen the appearance of the facade.

Instead of porcelain stoneware slabs, you can use siding. It is attached to the guides with self-tapping screws.

Restriction on performance of work

Despite the great popularity of a ventilated facade, all technical conditions must be met for its use. There is a certain limitation for performing such work: it is forbidden to use hinged systems without a project. In this case, the possibility of assessing the correctness of the installation after its completion is lost.

Installation is allowed at any time of the year. Extreme weather conditions are an exception. Severe frosts also impede work, as the power tool no longer functions effectively.

Ventilation facades have unique technical characteristics, simple installation technology, and affordability for middle-income buyers. This makes the finish in demand.

The systems are highly durable and practical. However, only high-quality proven materials are needed for installation.

Subject to the installation technology and taking into account all the nuances of the process, the finish will last up to 50 years.