When building a house, facade decoration takes an important place. I would like to make it beautifully and inexpensively. Moreover, these concepts are most often mutually exclusive. The standard low-cost solution is plastic siding. Sometimes this is unsuitable for aesthetic reasons. A wet facade applied to polystyrene foam is a beautiful solution, but too expensive. Therefore, people are looking for other unusual solutions. One of the interesting options may seem to be a soft roof for the walls of the house outside. This type of decoration is exotic for our country, but the experience of using such a facade is increasing every year.

General information and characteristics of shingles

Shingles or shingles are roofing materials created by individual shingles. The base is modified, oxidized bitumen. All this is covered with stone granules, fiberglass. Shingle is a separate plate 1 m wide by 30-35 cm wide with a characteristic repeating pattern.

Different shapes of shingles give the laying of the material a unique flavor and pattern. Bituminous shingles are used in construction on complex roofs, facades of houses due to their plasticity. The covering of the house after installation can imitate chips, shingles, slate, shingles, and other materials. In terms of reliability, shingles are not inferior to them, and some parameters exceed the original ones. The main thing is to choose the right tiles, to carry out installation.

The material can be easily laid on a dome-shaped surface, used for facade cladding. At the same time, it does not require a sharp slope for moisture to escape. The minimum is only 11 degrees. Soft tiles can even be laid on the surfaces of houses with a negative slope.

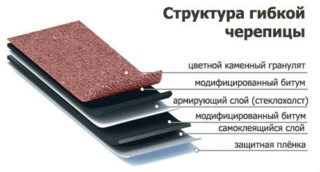

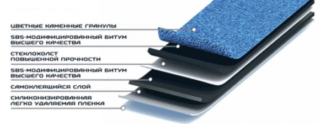

The composition of the tiles of the soft facade by layers:

- stone dressing (granulate);

- bitumen with a modifier;

- fiberglass;

- bitumen with a modifier;

- bituminous glue;

- protective film.

Stone granulate performs a decorative, protective function. Natural materials are used to make it - shale, anthracite or basalt. Only blue tiles are used to improve UV resistance. Therefore, this material is more expensive for most manufacturers.

The next layer is modified bitumen... The ability of bitumen to be soft, plastic, stretch, compress without damage affects the durability of the soft roofing for the facade. This layer is especially important in areas with critically low or high temperatures. The ability of bitumen to be elastic is given by SBS polymers. Another type of bitumen is oxidized material. When enriched with oxygen, the material is artificially "aged". At the same time, its service life increases several times. However, shingles become brittle, unable to withstand low temperatures. Therefore, it is suitable only for southern regions without severe frosts. Due to its rigidity, it is not able to adapt to thermal shifts of the battens.

It is not only the quality that is important, but also the amount of bitumen in the material. Cheap samples contain a little bitumen solution - about 800 g / m². In good samples, the proportion of bitumen is higher - up to 1300 g / m², according to the European standard EN 544: 211. In 2015Russia has adopted its GOST 32806-2014, which describes the technical conditions of production, material characteristics. Up to this point, all requirements for composition, installation, operation were based on the European standard. Russian GOST - adaptation of the material to local conditions with minor changes. In this regard, it has a degree of compliance with MOD, which means its modification.

Laminate shingles have more bitumen than single layer materials.

The basis of the material is glass canvas, not paper, as in roofing felt. Fiberglass perfectly protects against mechanical damage, longitudinal stretching of the material.

The bottom layer of the tile is processed bituminous glue for comfortable fixing on any lining material - wood, OSB, plywood, underlay carpet.

Bituminous glue is covered from pollution protective film.

Soft tiles differ not only in shape, but also in the number of layers. The more there are, the more durable the bitumen tile. The multilayer material looks embossed, which improves its appearance, but increases the cost many times over.

Features of the use of flexible shingles

When choosing a soft material, several parameters are important:

- Before buying, you need to present a general appearance, an architectural solution. The tile should organically fit into the overall ensemble of the building.

- For durability, it is better to choose a material with basalt granules - it retains the freshness of the color longer.

- If the budget is unlimited, it is worth choosing well-known manufacturers with a multi-layer canvas, a written guarantee. You should choose a supplier with your own production.

- It is optimal to buy tiles with a shelf life of up to 6 months. from the date of manufacture. Its adhesive composition has not yet dried.

These recommendations are general for all types of soft roofing. When choosing soft tiles, you need to pay attention to some features:

- Packages must be of the same production date. During installation, shingles are mixed to avoid variability.

- During transportation, a small loss of stone chips is possible. If the surface has become completely smooth, this is an obvious defect.

- When placed on a complex-shaped facade, the shingle sample should bend freely, return to its original state. This is irrelevant for flat surfaces.

- They immediately check the thickness of the shingle - it can be produced in single-layer, double-layer, multi-layer.

- The smell of bitumen upon purchase indicates the evaporation of the binder. Over time, the shingle will become fragile, lose elasticity under the influence of sunlight.

The choice of material should be approached responsibly. With the right approach, the outer coating will last for decades.

Advantages and disadvantages of a soft facade

Soft bituminous coating has many advantages over other materials:

- Tensile strength, resistance to bending, due to the introduction of fiberglass into the base of bitumen impregnation.

- The ability to create multi-layer materials with greater strength.

- Durability. Service life - half a century. Use in any climatic zone.

- Flexibility, elasticity allows you to cover complex wall reliefs, to embody the solutions of designers.

- Light weight does not require additional reinforcement of the lathing. One square meter weighs 3-10 kg.

- Resistant to mechanical damage, UV radiation. Thanks to stone chips, special impregnations, the brightness of the tiles remains for the entire service life.

- Tightness, soundproofing. The shingles are packed tightly, in a single layer, forming an airtight surface that is not subject to leakage. Moss and vegetation do not form on the basalt surface, since the roof does not absorb moisture. The elastic material protects against the sounds of rain, hail, wind.

- Shingles for the facade of the house have an adhesive backing.Thanks to this, the adhesive layer is quickly applied without special tools. Flexible shingles are equally successfully used for laying a new coating or repairing an old one. Single sheets are quickly replaced with new ones in case of damage.

The cost-effectiveness of laying, in comparison with metal tiles, compares favorably with a soft roof. Waste in the case of using metal tiles is up to 30% on difficult terrain. The shingles of the soft bituminous facade are laid without waste.

The material has increased fire resistance - it is certified according to the middle class of flammability. Bituminous impregnation does not support combustion, and stone crumb protects the outside.

The material with double fixation is resistant to gusts of storm winds.

During manufacturing, the shingles are packed into packages that are easy to transport to the site. On site, the individual sheets are easily lifted for assembly.

Universal bituminous shingles are in good harmony with various facade materials - brick, wood, metal, metal or vinyl siding.

Along with the obvious advantages, the material has a number of disadvantages:

- The minimum angle for the descent of rain, melt water is 11 degrees.

- The need to strictly follow the styling technology. Installation is carried out in the off-season. Too high a temperature softens and deforms the shingles. Warping of the material is possible in cold weather.

- Rough surface traps dust, debris, leaves.

During operation, it becomes necessary to clean the surface with a jet of water. Stubborn dirt is removed with a brush or broom.

Instructions for decorating a house with your own hands with flexible tiles

- The optimal laying time is off-season at a temperature of 15–20 ° C. There should be no wind.

- The roofing material should be stored in a warm room, without sudden changes in temperature, avoid direct sunlight.

- The protective layer of the shingle is removed only before installation. Otherwise, it will dry out quickly, lose its adhesive properties, and the tightness of the assemblies will decrease.

- It is impossible to rely on freshly laid material due to its deformation.

Laying the material is not particularly difficult. However, at first, a number of preparatory work is carried out.

- A vapor-waterproofing film is mounted on the crate to protect against condensation and prevent the insulation from getting wet.

- A ventilated layer is made on top of the vapor barrier.

- The soft facade is laid on a continuous flooring made of boards, OSB-boards, plywood. There should be no gaps and level changes. The maximum height difference should not exceed 1-2 mm. Using boards while drying may warp the base.

After laying the solid base, proceed to laying out the shingles.

- Marking the base will facilitate the laying process. It is worthwhile to draw vertical, horizontal stripes with a vertical step of about 1 m, horizontal - 0.8 m. Specific values are adjusted to the size of the shingle, they can fluctuate in one direction or another.

- You need to prepare the foundation for the start. It is made from shingles without petals. They must be removed on a flat wooden surface with a sharpened knife. Instead of a ruler, it is allowed to use a straight wooden block, a long level or other available material.

- After removing the protective film, the base is coated with a special mastic. The width of the coating is about 10 cm, 1 cm is left from the edge. It is recommended to use only bitumen-based adhesives. They work best with soft bituminous roofing material. The thickness of the composition should not exceed 1 mm. After mixing, the two-component adhesive should be left for 15 minutes. for settling. It is necessary to use the prepared mastic within 40 minutes while the polymerization process is in progress. Further, the adhesion decreases.

- First, the basement framing is laid. The first element is attached at the very corner of the house with an indent of 0.5 cm.For fastening, special non-corrosive nails with a length of at least 25 mm, a diameter of 3 mm with a head of 9 mm are used. The step of fastening is 20-25 cm, with an indent from the edge of 2-3 cm. For a three-layer tile, the length of the nail must be at least 45 mm.

- Regular shingles are attached with petals. For example, brick-like material. The size of its shingle is 100 * 25 cm. Each element will require 8 hardware near the cuts of the petals, 2 on each side. This is done on purpose - the next rows will lay on top of the nails. The scheme for hammering hardware by the manufacturer must be performed flawlessly. Due to its thoughtfulness, the penetration of precipitation into the coating is completely excluded.

- Each row is shifted by half a petal. This action closes the fasteners with hardware, the front wall imitates natural material. It is easy to align the position due to the pre-made serifs at the ends of the shingles. The serifs can cling to vertical surfaces, making it easier to install the roof alone. This is how all flat facade surfaces fit.

It is much more difficult to lay tiles around openings, protruding elements. These works require precise cutting and measurements. Laying the shingles above the windows is done according to the same principle as above the plinth. The main thing is not to forget about the displacement of the petals, trimming the excess length. It is recommended to first lay the shingles around the opening on the right and left, and only then - from below, from above.

Correct design of door, window openings:

- Lateral metal trims are attached in the color of the material. If the width is small, the direction of the precipitation flow is taken into account.

- The upper platband is mounted with the condition of further closure with a shingle.

- The ebb is fixed. The fastening method is different, depending on the material of manufacture.

- Additional elements are adjusted to the size with metal scissors.

External, internal corners are made with special additional metal elements. Fastened with self-tapping screws for metal with enlarged caps. The planks are overlapped by 5 cm. The step of fastening the hardware is 30 cm. The self-tapping screws can be spread with glue and covered with crumbs from the cut elements - this makes the wall look better.

The method of installation to the eaves depends on the location of the rafter legs. In some cases, the gap is covered with a board painted in the color of the facade. Sometimes they buy special additional elements made of roofing iron.

Popular manufacturers of shingles

Top 6 on the market are occupied by the following manufacturers:

- Onduvilla. Its cellulose tiles are impregnated with a bitumen-mineral mixture and are in the form of slate. Low weight 4 kg / m², low price, reliability allowed the coating to spread on the farm. Price: 136-151 r / m².

- Docke Europa. Lightweight covering for walls, roofs of any configuration. It is used for cottages, low-rise construction. The required slope is 12-90 degrees. Cost: 189-210 rubles / m².

- TechnoNIKOL Shinglass Classic. Produced at 2 factories owned by the Russian Federation. In Lithuania and Ryazan, at a Russian-Spanish joint venture. The material is made using imported equipment. Strict control is carried out at each stage. Density 2.9 kg / m². Price: 235-259 rubles / m².

- Icopal Plano Natur. Suitable for the most demanding outdoor coatings. An excellent combination of price-quality factors. Long-term manufacturer's warranty. Produced in France, Finland. SBS-modified bitumen is used. The dense, reliable material attracted the designers and made it possible to cover complex surfaces. Two layers are impregnated with an antifungal composition. Density 8.9 kg / m². Price: 492-520 r / m².

- CertainTeed (USA) is represented by a palette of over 20 lines, 150 colors. Has a lifetime guarantee, is the standard of quality. Two-three-layer execution. During installation, the layers are sintered. Weight 12.47 kg / m². Cost: 801-870 r / m².

- Siplast bituminous tile. Exclusive, very strong, durable material.It is used on pitched surfaces with a slope of 16 degrees. It features a dense PVC base with antifungal impregnation. Density 17.5 kg / m². Price: 1 230-1400 r / m².

There are many suppliers in the field who do not always adhere to established standards. Therefore, you should always pay attention to the prominence of the production.