Sheds and covered gazebos for barbecues allow you to entertain guests outdoors in any weather. The barbecue canopy can be of any shape, made of various materials. The structure is made separate on the site, attached to housing, other buildings. Sheds are built in the form of portable folding umbrellas, awnings, or made stationary.

- Structural features and roofing materials

- Frame options

- Pros and cons of different coatings

- Varieties of awnings

- Roof structures

- Drawing up a drawing

- Required tools

- Installation features

- Concreting

- Laying brick and stone pillars

- Assembling the timber frame

- Manufacturing of a metal frame

- Canopy option with hood

- Coating installation

- Painting the structure

Structural features and roofing materials

The covering material is fixed to the roof structure supported by strong struts. The pillars are reinforced with struts, corner struts. The frame is installed on the base; for mobile models, a support frame from a steel profile is welded at the bottom. Along the edge of the canopy, gutters are provided for draining rainwater.

The type of coating is chosen depending on the conditions of installation and operation. Materials used:

- cellular and solid polycarbonate;

- roofing steel;

- soft bituminous shingles;

- profile sheet;

- metal tiles;

- slate;

- wood.

For arched canopies, take polycarbonate, steel or bituminous tiles, since the material bends easily.

Frame options

The canopy over the barbecue can consist only of a roof on pillars or have side parts. For a small house, non-combustible frames made of brick, iron are placed over the barbecue, since sparks reach the racks. Spacious sheds are built of wood, stone, aerated concrete, and foam concrete are also used. Combined options are used, when the pillars are laid with bricks, and the roofing elements are made of metal.

The main types of support structures:

- The frame is made of wood. The material is convenient for sawing, processing. For supports, bars are used, the cross-section of which is not less than 100 x 100 mm. You can change the timber with a rounded or simply barked log. For strapping, elements with a section of 75 x 75 mm are taken, gable rafters are made with a bar of 75 x 50 mm, for a single-pitched almost flat roof material with a section of 75 x 100 mm is required. Double boards of 30 x 120 mm are used, placed on the edge.

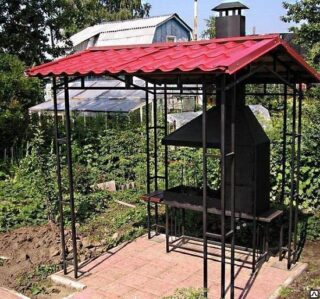

- Metal frame. A profiled pipe of 40 x 60, 40 x 60 mm is used, which is easier to cut to size. It can be bolted together, so there is an option for making a collapsible frame for rearrangement. There are models made of round hot-rolled pipes, they are easier to bend for arches. The diameter is used for racks from 50 mm; thinner material is placed on the roof. The assembly is carried out by welding.

Stone supports are made of red and silicate bricks, cement-sand mortar is used. Front facade stones do not require processing, ordinary bricks are tiled or plastered.

Pros and cons of different coatings

A small barbecue shed in the country is made of material that is required to be incombustible. For high sheds, this is not so important, since hot air on the way up has time to be diluted with side currents. The coating must withstand temperature extremes when hot vapors act inside and cold rain falls outside.

The use of materials depends on the properties:

- Wood. The material is environmentally friendly and has a beautiful appearance.Differs in sufficient strength, works well for bending. Pretreated with antiseptics and fire retardants to protect against rot and rapid fire, the surface of the boardwalk is painted.

- Metal. Long-lasting material will last 2 - 3 decades. The metal tile does not burn, it has a colorful, beautiful look, but for its installation you need a crate made of solid OSB plates. They are used on rectangular slopes, since segmented roofs increase material consumption. Smooth steel roofing sheets are joined together in a lock, they are also durable thanks to a special layer.

- Polycarbonate. Attractive because of its translucency. The material expands and contracts as temperatures change, so it cannot be rigidly attached to the rafters. They are used for an arched, arched roof, take honeycomb-type polycarbonate or in the form of a solid plate.

Sheets of corrugated board do not require frequent lathing for installation, they are cheaper than metal tiles. A protective polymer coating is applied to the surface of galvanized steel to prevent the effects of bad weather. The cut edges are additionally treated with paint.

Varieties of awnings

Barbecue awnings are open, semi-closed and fully covered in the form of gazebos. The first type protects against rain, snow. If a parapet of 90 - 120 cm is provided below, the side wind will not interfere with the operation of the barbecue or barbecue. Barbecue gazebos are rarely made, you can consider the option for placing tables there, and the canopy itself over the barbecue should not be completely closed.

Distinguish between simple projects, small and free-standing buildings. Simple awnings include four posts that support the strapping beam. The structure is often folding, and non-combustible soft materials are used for the roof.

Minimalistic awning designs are presented in the form of portable umbrellas that can stand on their supports or be attached to the barbecue. For them, a professional pipe is used, corners No. 45, 50. Free-standing structures are made stationary, their dimensions are 2 x2, 2 x 4 m, the supports for them are made of brick, metal.

Roof structures

Roofs are made high with a steep slope, they are made flat.

The execution technology depends on the type:

- One- and two-slope structures require trusses. Elements are boiled from metal, made from wood. For a gable, triangular trusses with sharp corners at the base are chosen, and single-pitch trusses are performed on rectangular products. The trusses are installed side by side, a wooden or steel crate is attached to the upper elements.

- Arched can be made of metal, brick. Wooden ones are rarely made, since ready-made expensive parts from an array will be required. The metal profile is formed in the form of an arch on a bending machine, and brick arches are laid using a special template. The cross beams are used to fix the roof covering.

- The corner roof is built at the junction of two walls at an angle. They can be flat, triangular or arched slopes. Due to the large number of joints, a special requirement is imposed on the sealing of joints. The roofs of such a structure are made of metal and wood, covered with polycarbonate, slate, corrugated board.

There is a separate category of barbecue or barbecue awnings, which are made in the shape of a canopy. The structure is attached with one side to the wall of the house. Such a structure cannot be large in depth (offset). In width, the visor is mounted on the wall, so this size is not limited. Use wooden blocks and a metal profile.

Drawing up a drawing

Each owner can make a diagram with his own hands for a barbecue area with a canopy, taking as an example a typical sketch from the Internet.

The design indicates:

- layout with a location in the yard;

- top plan of the structure with dimensions;

- vertical view of the canopy with the indication of elevations.

The project is needed to calculate the material, especially for large buildings.It is easier to make changes in the drawing than to alter the assembled structure.

Required tools

Be sure to need a measuring tool, for example, a simple or laser tape measure, a carpenter's square. To coordinate the correct installation of the elements, a construction bubble or laser level, a plumb line is used.

Other tools:

- shovel, concrete preparation container;

- circular saw, electric drill, grinder, welding machine;

- hand saw, screwdriver, hammer, pliers.

For marking, you will need pegs made of wood or metal, a strong cord, and a rope.

Installation features

Concreting

They dig holes under the metal and wooden pillars with a garden drill, make a bed of rubble and sand below, then concreting the surrounding space. The lower part of the support is wrapped with roofing material or smeared with molten bitumen three times. When pouring, concrete is poured with a shovel, a piece of reinforcement, or a vibrator is used to distill air.

Under the brick pillars, they dig a hole 5 cm larger than the section on all sides. At the bottom, 5 and 10 cm of sand and crushed stone are poured, rammed, spilled with water. Lay a layer of waterproofing so that it completely covers the walls. A reinforcing cage is made, the rods are tied with wire or welded. The pit is concreted, then they wait 12 - 15 days to start laying.

Laying brick and stone pillars

A cement-sand mortar is prepared at a concentration of 1: 3 (cement, sand, respectively). When performing masonry, vertical and horizontal seams are tied up. After 2 - 3 rows, a stamped metal mesh is installed or reinforcement with a diameter of 4 - 6 mm is placed so as not to increase the thickness of the seam.

Natural stone is more difficult to lay because it does not have a clear shape. The edges of the pieces are chipped off a little to make them approximately equal along the edges. The dressing of the seams is also observed, the solution is removed immediately, since after hardening it is difficult to select it from the irregularities on the surface of the stone.

Assembling the timber frame

After concreting the racks, a transverse strapping is made from a bar. It is nailed to the end of the pillars. To connect the corners, the half-tree method is used. Sometimes the ends of the other two runs are placed on the beams from opposite sides, while the wood for joining in the bars is not chosen. The rafters are fixed with brackets, bolts.

Before installation, the parts are impregnated with hot linseed oil (+ 60 ° C) or store-bought antiseptics. After the frame is made, it is painted with oil or acrylic paint.

Manufacturing of a metal frame

Steel elements are assembled by bolts or by welding. The bolted connection is regularly checked and the nuts tightened.

Manufacturing steps:

- the cross members are fixed to the uprights at the selected height;

- cut out corner braces, fix in the right places;

- small farms are welded on the ground, then raised, and overall ones are made at the top of the frame.

After installation, the metal is degreased, covered with an anti-rust agent, and painted with pentaphthalic or latex compounds.

Canopy option with hood

A hole is made in the canopy for the passage of the pressurized pipe. Forced ventilation is provided by installing an extractor hood. The chimney structure must not touch the wooden roof elements and flammable roofing. The chimney is insulated with mineral wool, foam, expanded polystyrene from the elements of the rafters and lathing.

Coating installation

They use types of corrugated board that are intended for roofing work, such a material has a standard wave height so that it does not sag from snow, wind action. For metal tiles, you need a solid base, and not separate slats.

The step between the elements of the lathing is chosen depending on the angle of inclination, the strength of the material is taken into account. An increase in the slope of the slope leads to a decrease in snow load, but increases the effect of the wind.

Painting the structure

A layer of paint on the surface protects wood, iron from rain, atmospheric moisture, and therefore extends the service life. Different types of paints are used, based on the cost, the type of coating being created.

The frame is painted with a spray gun, a brush, and a spray gun is used. In the process, they try to apply paint in hard-to-reach places. The composition is applied in 1-2 layers, after which it is coated with oil or water-based varnish.