Siding is an opportunity to move away from the usual facade decoration. There are many varieties of this material on the construction market: large boulders, flat and rubble types. If you prefer a capital approach to the arrangement of a building, study the technology of cladding a house with stone panels.

Choice of materials for panels with imitation stone

Experts recommend using 1 to 3 shades of panels for decorating a house under a stone. Highlight design elements, such as corners, with color or a large texture. Darker and more voluminous details are traditionally used on the foundation, light inserts are used for the main area of the house.

The cladding of buildings in the courtyard looks ergonomic if the basement and the rest of the buildings on the site are sheathed with the same siding.

Manufacturers produce panels with imitation stone, designed for different operating conditions:

- Metal - plates are made by stamping. The blocks are coated with a polymer compound to protect the galvanized steel. Additionally, a layer of decor is applied, imitating a stone. The panels are distinguished by their high weight, thickness and price.

- Fiber cement blocks are made from sand and cement with the addition of mineral fiber and cellulose. Thanks to the composition, the surface is hard, UV-resistant and resistant to atmospheric precipitation.

- Vinyl - plates made of PVC are popularly known as "lining". This material is not suitable for sheathing a house from the outside. However, manufacturers have developed PVC panels with a special coating for outdoor cladding. Durable plastic is resistant to temperature extremes and mechanical stress.

- Polypropylene protects the surface from the formation of defects, withstands atmospheric stress. In operation, it differs in slight compression at low or high temperatures.

- Acrylic is similar in technical parameters to vinyl. It has similar advantages, but has a higher resistance to temperature extremes. Another plus is chemical neutrality.

Stone cladding panels for house facades are also used for finishing fences. Designers note that it is not necessary to sheathe the entire building with blocks, it is enough to refine one structural element or floor.

Positive and negative sides

The main advantage of stone siding is its service life - up to 50 years. It is achieved due to its resistance to wind, precipitation and temperature extremes. The panels also have the following advantages:

- suitable for installation on the front of the house;

- easy to install;

- not subject to corrosion;

- low price;

- easy care;

- weight 3-5 kg / m²;

- resist the fungus.

Blocks with imitation stone (130 MPa) for outdoor use are inferior to natural material (40-170 MPa) within the limits of compressive strength. Given a decent list of positive factors, this nuance is negligible.

Choose panels for a stone that are fastened to each other. This technology does not require the installation of a frame made of wood or metal.

Technical parameters and size range

Facade blocks made with imitation of natural stone are optimal for protecting the building from the outside.Select panels based on the climatic characteristics of the region of residence. Thanks to the beveled edges, the seamless coated plates create a one-piece construction. At first glance, it is difficult to distinguish an artificial block from a natural stone.

Cleaning the surface does not require much time - it is enough to periodically wipe the plates using laundry soap.

Cladding blocks are resistant to temperature extremes and UV radiation. Depending on the material, they are not deformed under the influence of heat (up to + 50 ° С) and frost (-50 ° С). Such technical characteristics are in demand throughout Russia, since materials that are resistant to heat and cold are needed for cladding a house.

When starting to work on cladding a building with stone blocks, select the appropriate panel dimensions (width / thickness):

- fiber cement: 6-35 / 305-1500 mm;

- metal: 5-13 / 190-210 mm;

- vinyl: 0.6-1.3 / 220-275 mm;

- polypropylene siding: 6-10 / 215 mm.

Almost all panels imitating stone have a perforation in the upper part for fastening, which is closed by the next block. The actual width of the materials will be 1-2 cm smaller than the actual width. Consider this feature when calculating.

Features of house cladding with panels with imitation stone

Facing with stone facade blocks is carried out independently or under an agreement with a construction company. Before purchasing materials, calculate the required number of blocks for house cladding. The volume depends on the parameters of the slab and the dimensions of the surface. When determining the area of the walls, do not take into account window and door openings. Additionally, purchase external and internal corners, guides, platbands and strips.

For self-assembly, prepare the tools:

- building level;

- stepladder or woods;

- drill;

- knife;

- tape measure and pencil;

- saw.

It is recommended to fasten the elements with self-tapping screws with a galvanized coating. If thermal insulation is planned, first install vapor barrier materials.

Siding from the Nichikha brand (Japan) was recognized as a quality imitation of stone. Russian analogue - panels for cladding brand "Rospan".

Cladding technology

Siding can be ordered according to individual sizes and designs. The panels are developed based on the parameters of a specific object and the wishes of the owner of the house.

Build a ventilated facade with a gap of 2-3 cm. To do this, install a counter-lattice made of wooden slats or metal guides. To avoid distortions in the finished facade, place the frame elements in one plane.

Features of the technology of cladding a house under a stone:

- Position and secure the planks in place. Start from the bottom corner.

- Install horizontally, making a gap of up to 5 cm between the panels and the ground level.

- Place the subsequent elements in the groove with a slight indentation. Fix the cladding panels tightly to the battens.

- In the center, pre-make holes for self-tapping screws. When attaching, do not deepen the cap to the end, leaving room for thermal expansion of materials.

- Do not install façade units tightly to the roof. It is recommended to make an expansion gap.

- At the end of the work, the corners are mounted on the cladding.

The main condition for installing panels under a stone is compliance with thermal gaps. Under the influence of temperatures, the linear dimensions of the blocks decrease or increase. Provide a small space to compensate for excess volumes when heating the facade.

Manufacturers rating

Among foreign brands stand out:

- Novik (Canada) produces facing blocks with a texture that imitates field, river and wild stone, hewn masonry and limestone. The brand's products are of high quality and from 2 mm thick.

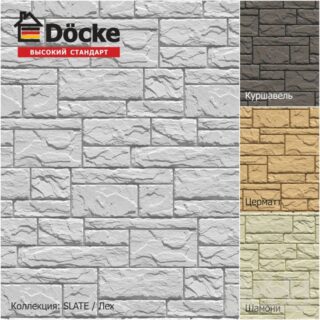

- Döcke (Germany) produces facade panels with imitation of rocks, sandstone and wild stone. The brand supplies 6 block collections to the Russian construction market.

- Nailaite (USA) produces three series of siding for cladding facades of houses - rubble, natural and hewn stone.

- KMEW (Japan) is a manufacturer of fiber cement panels with a size of 303x45.5 cm with a protective coating. The brand's products are frost-resistant and contain special micro-granules that ensure a long service life.

The walls of the building need high-quality protection from atmospheric precipitation. Take care of the insulation and appearance of the house - use the facade cladding with panels with imitation of stone. Facing blocks will not only give the building an original design, but also extend the service life. Facade panels are a practical option for arranging the exterior.