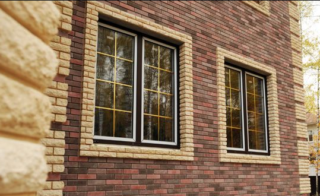

Facing with bricks of window openings is a great way to give the facade originality, expressiveness, own style and charm. This finishing option is not only aesthetic, but also practical, having a positive effect on the strength and durability of the building. Facing windows with bricks is a fairly simple process, but there are a number of nuances that must be taken into account at all stages of the repair.

The main functions of facing window openings with bricks

Industrial and domestic construction is carried out according to uniform standards, which imply the manufacture of window openings of a square or rectangular shape. The dimensions are determined by the design strength of the supporting structures. Having received real estate at his disposal, the owner can rebuild it, decorate, but not to the detriment of the reliability of the building. Brickwork around windows is not included in the list of prohibited activities.

The technology carries the following functions:

- closure of boring-looking gray concrete slopes;

- giving the opening of originality and originality;

- thermal insulation of the room by laying an additional layer of insulation;

- strengthening the structure.

If the load-bearing walls are not affected, a round window, hexagonal and even ellipsoidal, can be laid out in the brickwork, if the owners like it and is combined with the interior. The most important thing here is not to get carried away by the originality and to preserve the harmony of the facade.

Varieties of bricks

There is an extensive range of materials on sale that can be used to make a practical and effective brickwork above the window.

- Hyper-pressed rounded. Chips of dolomite, limestone, granite and marble are used as raw materials. The ingredients are mixed with stone dust and moistened. The mixture is placed in molds and then pressed under high pressure. In terms of strength, finished products occupy an average position between concrete and natural stone.

- Shaped single hollow. Products differ in a variety of shapes and configurations of voids. The presence of beveled edges allows you to create a pleasant-looking surface from elements with rounded contours.

- Clinker embossed. The material is quite expensive, as it is made from rare types of clay and requires a lot of energy. Differs in high thermal insulation characteristics. The texture is imparted during the molding process.

- Glazed. The front glossy surface protects the block from moisture and abrasive substances, as it is highly durable. Various models imitate substances such as wood, stone, fabric. The price is the highest among analogues.

- Silicate brick. The most budgetary material that is used in cladding. It is rarely chosen due to its nondescript and low strength.

When choosing, you should not put price at the forefront. Cladding is done for decades. It should be pleasing to the eye and perform its functions efficiently.

Cladding methods

The laying of window openings from facing bricks will not cause any particular difficulties, if you initially plan everything correctly, use high-quality tools and materials, and observe proportions and symmetry.

There are such methods of facing window openings with bricks:

- Rough.It is used when masonry is performed by an inexperienced worker, when using stones from an uneven surface or creating a complex shape with gaps. At the end of the solidification of the solution, the finishing of the structure is carried out using decorative plaster.

- Fine. Assumes precision work with high quality materials. The masonry is carried out with millimeter precision, no additional finishing is required after its completion.

The choice of method is determined by your own abilities and the configuration of the purchased brick.

Required tools and materials

If the cladding involves the arrangement of the lintel (maximum program), the following tools will be required for work:

- perforator, grinder, screwdriver;

- level, tape measure;

- scissors;

- spatula, trowel, trowel;

- hammer, mallet;

- pliers;

- hacksaw for wood;

- marker.

You need to purchase materials:

- facing brick;

- cement, sand, fine gravel;

- cellophane;

- Scotch;

- sealant;

- liquid antiseptic;

- fittings;

- binding wire;

- decorative plaster.

If the cladding will be carried out at a height, you should take care of the safety devices in advance. A respirator, protective gloves and goggles must be prepared to protect hands, eyes and breathing. It is advisable to have a construction helmet.

Stages of brick cladding of window openings with your own hands

A rectangular opening is made as follows:

- A piece of steel brand or corner is cut in such a length that its ends overlap the edges of the opening by 50 cm. The steel is treated against corrosion and then secured in place.

- Brick blocks are cut in such a way that, after laying, their edges protrude flush with the previously laid vertical masonry on the sides of the opening.

- A cord is pulled along the corner to indicate the level of the stones. They are laid with an opening of 10 mm. For accuracy, two pieces of a pin of the corresponding section are used.

- Formation of a masonry joint with a depth of 3-4 mm. A chisel or other tool of a similar shape is used.

- On top of the laid out row, the next level is laid out with the surface of the wall. This must be done immediately in order to press the protruding edging.

In conclusion, the drops and rushes of the solution are removed with a brush and rag.

- Installation of metal profiles with a third of the brick length from the wall.

- Laying out the layout to the middle of the window opening. Determination of the center of the circle using a board attached to the wall and a cord with a pencil. Derivation of a circle from the layout.

- Stone marking. Dismantling the masonry, transferring it to a horizontal position on a flat surface on the ground in accordance with the marking.

- Work with a grinder and a grinder to shape the blocks so that, after assembly on the wall, they form a perfectly round opening.

- Making a wooden template that will support the fragments until the mortar sets. Screwing the rim to the wall.

- Laying bricks up to the middle of the circle. Then a break is taken for a day. The process is then repeated until the last top wedge is inserted.

The rim can be pulled out immediately after the end of work, since the masonry is self-supporting and is highly durable.

The arch is a combination of vertical trim and the creation of a semicircle. The process goes like this:

- Erection of vertical masonry protruding beyond the wall on the sides of the slope.

- Making a semicircular template from board, plywood or sheet steel. Fastening it to the side walls.

- Arched ceiling installation.

After the solution has solidified, the wood is removed, and the metal, subject to anti-corrosion treatment, is left.

Standard openings are not distinguished by sophistication, but this drawback is easily eliminated. Today any company will manufacture a window block of the most complex shape - oval, round, polygonal. The window must match the building's interior in size, color and layout. Otherwise, the building will look ridiculous and tasteless.