Sheathing for PVC panels is widely used in residential and commercial areas. It allows you to mount these products in places with humid air (for example, in a bathroom) and unstable temperature conditions (including where there is no heating). Since the lathing under the pvc panels does not tend to deform, it can be used many times.

Description of PVC panels and their advantages

This type of finishing materials for walls and ceilings is one of the most practical. Products can withstand fluctuations in the microclimate and can serve for a long time. Other pluses of decorative plastic panels include:

- simplicity of installation work, no need for highly specialized qualifications and high installation costs;

- attractive and modern appearance;

- environmental Safety;

- minimal pollution of the surrounding space during work;

- the possibility of installation on surfaces made of all basic building materials: wood, reinforced concrete, brick;

- waterproofness, tightness of joints;

- minimal need for preparatory work;

- soundproofing qualities;

- the possibility of laying electrical wiring.

The material attracts by its ease of use, lack of the need for complex care. Products need only be periodically dedusted. You can remove dirt with a soft sponge and detergent. Since plastic panels do not rot and do not lose their properties under the influence of moisture, they can also be installed in bathrooms, on balconies.

Variants of fastening the crate for PVC panels

The lathing for panel mounting can be made of different types of materials. In the past, wood was the main raw material for such structures. Now it is increasingly being replaced by plastic and metal profiles.

Frame made of wooden bars and slats

This is the most affordable and budgetary material, but its use imposes a number of requirements on the premises. In addition, the structure is not particularly durable: it will serve for about 5 years. Since wood deteriorates from moisture, the room must be dry. Beams and slats must be selected very carefully. Poorly dried, as well as curved, knotty or curved elements are not suitable as raw materials. Smooth slats with a cross-section of 2 by 2 cm are suitable. The moisture content in them should not exceed 18%. The tree must be treated with compounds that prevent rotting and fungal attack.

It is not difficult to mount the structure: the rails can be interconnected in any suitable way. If you plan to install them in a room with humid air, you need to arrange small cuts for circulation.

Application of plastic profiles

The lathing for plastic panels is increasingly made from plastic profiles. They are convenient in that they can be installed in rooms with different levels of humidity, including in a bathroom or a swimming pool as an alternative to ceramic tiles. Plastic does not lose its performance from regular contact with water. Also, the profile is good for its thinness, which does not reduce the space of the room.

The products are easy to install, they are not affected by fungus. The disadvantage of plastic lathing for PVC is the ability to install only on a surface that does not have pronounced irregularities. It is problematic to disguise pronounced curvatures and altitude differences with this thin material.

Metallic profile

Products have the greatest strength, while their weight is less than that of a wood profile. The metal profile is the only option that allows you to crate surfaces that have significant level differences. In addition, a luminaire can be built into this frame. However, the construction will cost more than plastic or wood.

In terms of the complexity of the work, the products surpass other options, while they do not need to be adjusted in size - all components included in the wiring diagram have typical dimensions.

The metal profile is impervious to water and temperature extremes, so the lathing made of it can last up to 15 years, if the integrity of the outer layer was not violated during installation.

Preparing for installation

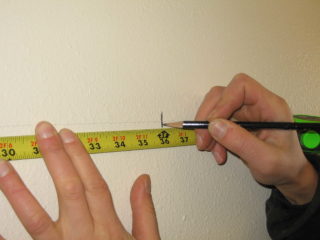

Before installing the battens for plastic panels, you need to prepare prefabricated components - sets of metal or PVC profiles. If it is decided to make a structure of wood, you will need elements of two standard sizes - 3 by 2 (for outdoor work) and 3 by 1 (for indoor). You will also need an electric drill, a drill with a dowel attachment, a building level, screws. To work with wood, you need a special hacksaw. A construction tape and tools for controlling right angles and evenness of lines (triangle, plumb line) are also useful. You can mark with chalk.

Correct performance of work implies an assessment of the surface evenness and its correction, if necessary. In old houses that have not undergone major repairs, level drops and various defects are very common. They also arise with a dismissive attitude towards building codes. In the bathroom, defects most often appear near the corner sections of the floor and ceiling. The most accurate tool for assessing the evenness of walls is a laser level. When, according to the measurement results, the differences exceed 0.5 cm, it is advisable to eliminate them. This can be done by removing the existing protrusions with a sander or by applying an additional layer of the mixture with an emphasis on the indentations. In the absence of a level, a coarser estimate is applied: a lantern is applied at the butt-joints, the areas of shading are highlighted and they are leveled. As a result, the differences should be a maximum of 0.1-0.2 cm per linear meter of the surface.

Some homeowners choose to ignore the leveling to save money. This is permissible when installing metal battens and having a laser level at hand. Having found with the tool the most protruding point on the surface, it is taken as the zero mark. Then, on the adjacent walls, which are at right angles to the lathing one, dots are placed showing the location of the leveled plane. The guides will need to be set at the zero mark. The method is well suited only for metal structures, since they provide long steel brackets for fasteners. The disadvantage of this method is that the useful area is lost during its implementation.

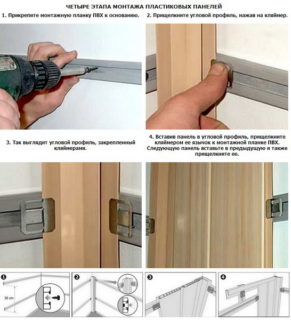

Features of mounting plastic panels

On the walls

The boundaries of the installation of the lathing can be applied using a flat strip, a construction tape and a simple crayon. Then the assembly of the structural components is carried out. If wooden slats are used, dowels and screws act as fasteners. To control evenness, a plumb line and a building level are used.

If you have to work with an uneven wall, align with plywood linings. It is recommended to fill the area between the surface and the frame with an insulating material. This will also improve the soundproofing qualities of the room.

After the frame is ready, you can mount the panels themselves. If the latter have lost their operational properties, they can be removed and new ones installed in the same crate. Sometimes the profiles are placed at the level of the main joints of the occupant (hip, knee, shoulder) to prevent the panels from bending when the person touches the wall.

To the ceiling

The general installation scheme in this case is the same as for the walls. First of all, the distance between the planks differs. If, when working with walls, a step of 0.5-0.6 m is permissible, for the ceiling surface it decreases to 0.3-0.4 m.

The lathing under the PVC panels has a long service life, since it does not deform from the effects of the external environment. Before installation, it is advisable to check the evenness of the surface and, if necessary, level the differences.