The block house is a board for external wall cladding, made in the form of a segment of a rounded log. Sliced lining is cut from the edge sections of the log when cutting a square bar or obtained by processing the board on milling equipment. The cladding of the house with a block house gives the structure the appearance of a building made of logs, while there are no disadvantages of this type of structure.

Features of block house material

The properties of the material differ from other types of wood cladding in that during the manufacture the board undergoes complete drying, impregnation with drugs to reduce the degree of moisture absorption, flammability.

On the reverse flat side, 2 or more grooves are made to coordinate swelling and swelling, the front part is made in the form of a section of a circle. The lamellas are connected according to the thorn-groove type, on the opposite edges, the corresponding parts are made for a tight abutment.

Panels are made from various types of wood, more often coniferous varieties are used. Spruce, pine, cedar and fir are common because of their low cost. You can sheathe the house with a block house made of linden, larch, birch, alder. The material is distinguished by its strength, long service life, rich variety of colors and patterns of fibers.

Varieties of block house

Varieties of wood block house:

- Extra class - perfectly joined wood, without knots and protrusions;

- class A - an even area of the boards without scoring, chips and damage, several small ingrown knots are allowed;

- B - small defects, flaws and knots are allowed;

- C - many flaws, knots falling out, the category is used for finishing temporary buildings or utility structures in the yard.

On the outside, one or more waves are performed, so the building looks like sheathed with large or thin logs.

In addition to wood, there are metal and vinyl panels that are also used to decorate the walls of buildings.

Wood

The quality of the product is influenced by the type of raw materials and processing characteristics. After mounting on the wall, the material is coated with clear varnish or paint, even if this is the ideal Extra class. This finish will emphasize the pattern, in addition to the protective function. The coverage should be renewed at least once every 5 years.

Wooden panels are mounted on a perfectly prepared surface or a ventilated facade is made on a frame. The panels are lightweight, so they do not weigh too much on the base of the house. In terms of technical indicators and operational properties, the block house surpasses other types of cladding.

Metal

Lamellas are made of profiled metal, which is hot-dip galvanized on both or only one side. On the surface of the wall, the panels are connected with special locks along the longitudinal edges of the board. Steel elements weigh a lot, which is taken into account when designing the finishing layer. Impact dents remain on the surface of the strips that cannot be repaired.

The steel block house is time-tested, the finish is from 25 to 30 years without loss of appearance and quality, does not require periodic touch-up and varnishing.

Vinyl

Vinyl elements have advantages over wood paneling:

- resistant to water;

- difficult to ignite, stop burning in the absence of a flame source;

- do not rot, are not interested in microbes, fungi;

- differ in a variety of textures.

Vinyl block house in the cold can crack due to fragility. The panels change size under the influence of the sun, so a certain system is required to secure the parts. Plastic slats transmit noise and sounds from the outside; they are also not considered as additional thermal insulation.

Rules for choosing material for home decoration

Outside, the house can be finished with a block house made of various types of wood, but inside wet rooms, for example, baths, saunas, you need to sheathe hardwoods. The material is more dense, has increased moisture resistance.

The material differs according to the area of use. There are panels for the floor, others are taken only for interior cladding or used outside. In shape, strips are produced that resemble a bar, lining, log.

Outside, pine boards are more often used, which have sufficient strength. They take elements that are at least 150 cm in width - this is how the facade looks organic. The flawless surface of the log without knots will provide an aesthetic look. It is better to purchase the material directly from the manufacturer.

Pros and cons of a block house

The cladding changes the appearance of the old building, the durable lamellas look impeccable due to the ideality of the shapes. The material combines a reasonable price and decent quality. Installation does not require specific knowledge and professional skills - anyone can fix the block house outside the house if they wish. The main thing is to study the intricacies of the frame installation technology, how to attach thermal insulation and moisture protection.

The material tolerates external influences, wooden lamellas are easily restored, belong to the category of environmentally friendly materials, and form an additional layer of insulation from the cold.

The disadvantages of a block house are that the wood burns quickly and therefore requires processing. The material is saturated with moisture, which comes in when directly wet and is transmitted from the atmosphere.

Required tools and materials

Other mounting materials:

- tape measure 5 m, square, level, plumb;

- screwdriver, electric screwdriver, drill, puncher;

- hammer, pliers, rubber mallet.

The block house system does not provide for corner or framing strips, therefore, metal elements are used. For the lathing, take rails 50x25, 50x40 or use galvanized profiles of the g / cardboard system.

The frame is attached to the wall with dowels, self-tapping screws, depending on the material of the vertical fence. Finishing panels are fixed to the frame elements with wood screws or "flea beetles". Acquire paints and varnishes for surface finishing.

Preparatory work

Before finishing, they completely clean the work surface inside or outside the house. They remove lamps, gutters, vertical pipes. The exfoliated parts are knocked down on the square, the wall is reinforced with plaster, the masonry is repaired or the wooden elements of the wall are replaced.

If a rack frame is chosen, the bars are treated with linseed oil or special antiseptic preparations. They make a calculation of the material, while the square is taken over the area of the facade.

In the process of preparation, a heater is placed on the wall. The plate variety (polystyrene, expanded polystyrene) is placed between the frame posts. Mineral, stone wool is attached to the wall, and the slats are placed on top to obtain a ventilated gap between the insulation and the waterproofing film.

Do-it-yourself house cladding features

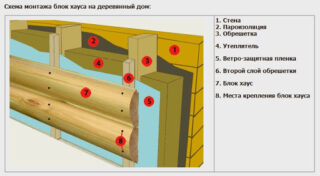

The main composition of the layers during finishing:

- insulation;

- lathing;

- waterproofing membrane with vapor diffusion function, wind protection;

- ventilation gap;

- block house layer.

With the help of the lathing, the curvature of the walls is leveled, ventilation is organized under the sheathing. The elements are fastened with a gap of 60 cm. The construction can be one or two layers. Installation of strips is done both from below and from above. The inner lamellas are fixed with the groove upwards to make the butt seam invisible.

The outer strips are turned with a groove downward to reduce the risk of rain drops.

Inside the house

After purchasing the material, it is necessary to acclimatize, for which the panels are laid out in the room for 48 hours so that their humidity becomes equal to the microclimate indicators.

The battens of the lathing are fastened perpendicular to the strips of material. The installation is regulated by a level or a plumb line, while aligning the general line of the wall. When laying the boards between the ceiling and the layer, at the bottom next to the floor, leave a gap of 5 - 7 mm for ventilation.

Fix the block house:

- clays;

- through the panel with self-tapping screws.

In the second method, holes remain, which are sealed with wooden corks with PVA glue. The inner corners are joined at 45 °, while decorative overlays are not used, or they are overlaid at 90 °, but additional elements are placed.

Outside the house

Outside, wooden lathing is rarely made, more often they use zinc-coated profiles:

System elements:

- profile CD-60;

- wall girder for strapping UD-25;

- bracket for fixing ES in sizes 90, 120, 160 mm.

The insulation is attached to the wall so that there are no gaps and gaps, and the brackets are held through the incised sections of the insulator. If necessary, fill the slots with foam. The film membrane is pulled over the slats so that it does not allow external moisture to pass through, but removes internal steam.

The strips are laid tightly connected to each other. Hammer the elements with a rubber hammer so as not to flatten the surface of the lamella. Docking along the length is carried out by installing vertical dividers against which the ends of all strips abut. Sometimes an exact fit of panels is used, the ends of which are cut at 90 °.