The entrance of cars to the site is carried out through the gate, the optimal material for the manufacture of which is corrugated board. The metal profile is distinguished by its versatility and ease of use. It can also be used to make support elements of the railing. For the manufacture of fence posts from a profiled sheet, it is enough to decide on the type of installation and study the technology.

- Types of support elements for corrugated doors

- Racks made of asbestos-cement pipes

- Brick supports

- Concrete goods

- Screw piles

- Pillars made of wood

- Supports for corrugated metal pipe

- The procedure for calculating the posts for the fence

- Work algorithm

- Installation instructions for supports

- Pole concreting technology

Types of support elements for corrugated doors

Decking is a bent steel sheet that is widely used in household plots. The material is durable, easy to maintain and resistant to precipitation. On the market, professional sheet is presented in a wide color palette at an affordable price.

There are two main types of material for fencing posts:

- The round cross-section of the supports does not require large financial costs, it can withstand loads. For installation, you need to dig in the elements and fix them.

- Rectangular purlins are designed for mounting to a profile pipe. The flat surface makes the welding machine comfortable to work with.

When organizing the construction of a fence, it is important to determine which posts are needed for the fence. Good material has a long service life. Craftsmen recommend choosing metal products, since they are easy to install and durable. Any materials can be fixed to such a frame, for example:

- Rabitz;

- asbestos and cement chip sheets;

- cellular polycarbonate;

- wood;

- steel profiled sheet.

The service life of wooden poles is 12-15 years, metal structures will last 3 times longer.

A quality profiled sheet is a material coated with plastisol, polyurethane or PVF-2 film.

Racks made of asbestos-cement pipes

Supporting elements made of this material are an alternative to wooden and metal posts. This is due to the low price, resistance to decay and rust. The products do not require painting or treatment with antiseptic agents. However, the material is relatively fragile, labor-consuming to install and does not differ in aesthetics.

Brick supports

Brick as elements of the fence looks solid and reliable. In terms of cost, the material is in the middle segment, optimally combining quality and price characteristics. It is necessary to involve specialists for installation. Due to these factors, this option is gaining popularity among the owners of houses and summer cottages.

Concrete goods

Supports are purchased or manufactured independently. In the latter case, it is necessary to assemble a wooden frame, fill it with concrete and reinforcement. Therefore, the best option for a fence from a profiled sheet is to use ready-made posts.

Screw piles

A reliable type of support elements, but not popular. This is due to the fact that it is not always possible to buy screw piles. In addition, it is necessary to prepare the means of mechanization, for example, levers are used in private construction. Such work requires skills, assistants and equipment.

Pillars made of wood

Wooden posts for fencing made of corrugated board are chosen because of their eco-properties and low prices. Before installing the supports, it is necessary to treat the surface against bark beetle and decay.Installation is not expensive, but the service life of a tree is no more than 15 years.

Supports for corrugated metal pipe

The metal pipe of the fence posts made of corrugated board is light and durable. However, with increased physical activity, there is a risk of dents and holes forming. Thin metal-based profiled sheet is a popular type of fence support.

The procedure for calculating the posts for the fence

Making calculations reduces labor time and material costs. With an indistinct joining of horizontal girders, the entire structure loses its strength. The number of posts determines the reliability of the fence, therefore additional stiffening ribs should be installed.

The calculation of materials is carried out according to the formula: the land area is divided by the distance between the racks, including the section.

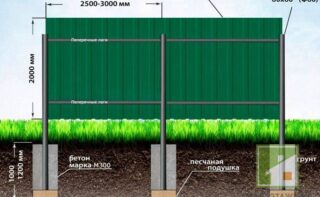

For a rectangular type, a gap of 2-3 meters is taken, for a round diameter - 2-2.5 m. The greater the weight of the structure, the less the distance is made. Fences made of mesh-netting and corrugated board mean the length between the elements ~ 5 meters.

Work algorithm

Profiled sheet is a light and thin material, therefore, it requires careful handling during installation. Scratches and severe abrasions can cause rust and deformation. Damaged sheets can always be replaced during operation, and corrosion can be prevented with special means and paintwork materials.

For the installation of pillars, it is necessary to determine the installation depth, which depends on three parameters:

- height and weight of the fence;

- type of fencing;

- feature of the soil.

The dimensions and weight of the structure, as well as the wind force, act on the supports. Together, these factors form the torque and upon reaching the peak there is a risk of the column breaking out of the ground. To strengthen the posts, you need to use concreting as a method of mounting the posts.

Installation instructions for supports

Having made a decision on the best way to install the pillars and the material for their manufacture, it is necessary to prepare the tools. Working devices for mounting fence supports are:

- manual or electric drill;

- shovel;

- sledgehammer;

- building level;

- plumb line;

- cords;

- container for mixing the solution;

- cement, sand and crushed stone.

The next step is to mark the perimeter for the future fence. The installation of jumpers and sections of the profiled sheet depends on the layout, since when shifting, it will be necessary to adjust the elements. As a result of an incorrect scheme, the fence may turn out to be uneven.

Algorithm for plotting a plot:

- install pegs around the perimeter in the places of future posts;

- mount the corner extreme supports, according to the level, then fill them with cement mortar;

- after hardening, tighten the cord, avoiding sagging.

- Place and fill the pillars consistently at the desired distance. The length between the supports depends on the size of the sheet, the weight of the structure and the type of soil. If the gap in the profile jumpers is 9-12 m, it is better to divide them into 3-4 sections.

- When finished with the assembly, treat the weld seams with an anti-corrosion agent, prime the surface and apply paint. It is recommended to use paintwork in the same tone as the profiled sheet.

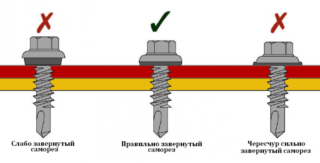

- The fixing of the corrugated board is carried out 4 days after the pillars are poured. This allows the solution to cure completely. The profiled sheet is fastened along each wave with self-tapping screws with a rubber washer.

If the ground level is different on the site, a stepped fence is mounted, the distance between the posts is reduced. Additionally, the structure is strengthened by installing auxiliary posts near the wicket and gates.

When filling the support elements with cement mortar, control the vertical level with a plumb line. Verify also visually in relation to other fence posts from the profiled sheet.

Pole concreting technology

For the correct installation of the pillars, you should choose the best option for fixing them in the ground. It is recommended to take into account the composition of the soil. For sandy and dense soils, the supporting elements should be concreted. The racks are screwed into the prepared wells or they use the driving method.

The concreting procedure takes place in several stages:

- Prepare a foundation pit 15-20 cm in diameter using a hand or power drill. Make a recess 0.7-1.5 meters. The exact parameter depends on the composition of the soil and the height of the fence. The higher the fence, the deeper the pit.

- Install the post in a vertical position - the area around you need to be concreted. While pouring, the mixture should be tamped.

The fences of their corrugated board are reliable and affordable designs. The best option for pillars is metal. This is due to the light weight, attractive appearance and the possibility of self-assembly.