Foil for a bath accelerates the temperature rise inside the steam room, since it retains heat, does not release it outside. The insulator is placed on horizontal and vertical surfaces to reflect infrared rays into the room. Which one is better to choose a foil for a bath is determined by the technical characteristics of various types. Use thin insulation, no more than 30 microns, or use a layer of aluminum based on a polyurethane foam lining.

- The principle of operation of foil insulation

- Advantages and disadvantages of the material

- Types of heat insulators with foil for a bath

- Foamed polyethylene with foil layer

- Mineral wool with foil

- Other types

- Sauna heater selection criteria

- The use of foil for warming baths

- Features of the choice of a foil layer

- Coating installation

The principle of operation of foil insulation

The insulator is based on a layer of foamed polymer particles, on which a foil coating is applied. The polished aluminum layer has a reflectivity of 97% and is glued by high temperature welding.

Thermal insulation qualities are based on the action of the effects:

- insulation of walls from internal steam;

- reflections of energy into the room.

Folgoizol absorbs noise easily, therefore it is often used for sound insulation. The rule that allows the insulator to reduce heat loss is to put the layer with the shiny metal side inside the steam room.

The material is not attached with an overlap, and construction aluminum tape is used for joining. There should be a small ventilated gap between the finish and the insulation to reduce heat transfer through adjacent hard surfaces.

One layer of foam foam will not be able to provide the required insulation efficiency. The material is used alone to reflect infrared rays or mounted in combination with traditional insulation. Thin foil insulation allows to reduce the thickness of the insulating layer. Use foil polystyrene foam inside and outside the bath.

Advantages and disadvantages of the material

The combined material is widely used to insulate not only the walls of the bath, it is used to insulate water pipes, drainage collectors and supply of drains to a septic tank.

Sauna foil has the following advantages:

- easy installation process;

- the coating is protected from water, sun, therefore it lasts a long time;

- relatively low cost without loss of performance;

- high elasticity allows you to put foil insulation on curved surfaces;

- products can be used to repair the old insulating layer, change if necessary.

If the canvas is dismantled during the repair of the walls, it will retain its characteristics and can be re-installed. The insulator does not react to the action of chemicals, which are always abundant in condensate droplets. Dust does not accumulate in it, microorganisms do not multiply.

The disadvantages of foil types are that they do not have rigidity, so they are not placed under a wet finish, such as plaster or putty. For gluing on a plane, special glue is needed, which increases costs.

Types of heat insulators with foil for a bath

During the heating of the stove in the bathhouse complex, more than 80% of the thermal energy moves with infrared radiation, only 20% comes from convection.Heat-reflecting foil material is becoming a popular material for the return of energy radiation.

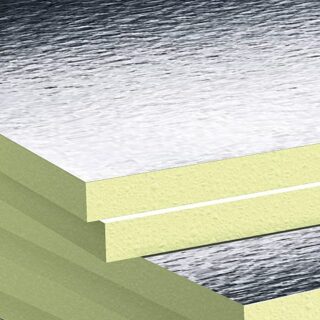

Combined aluminum foil for different types of baths differs in thickness, the material is produced in the range of 2 - 10 mm.

They produce types of insulators with aluminum foil:

- canvas with foil on one side;

- material with double-sided coating on the face and on the back;

- a layer of aluminum on the material with a self-adhesive layer.

Varieties of heaters are made, which differ in the base or insulating layer. The types of foil-clad material differ in the thickness and density of the aluminum film. Some canvases are made reinforced to increase strength and rigidity.

Foamed polyethylene with foil layer

It is better to use such foil in a steam room, since the material provides effective thermal insulation. Two or three-layer roll material combines the qualities of vapor barrier, waterproofing, thermal insulation and sound insulation. Produced in the form of polyethylene with or without an adhesive layer. It is called on sale Folgoizolone or Folgoizol, it is produced with different flexibility and density. In baths and saunas, it can be installed without an additional insulating layer.

Insulator technical parameters:

- heat conductivity coefficient - 0.031 W / mK;

- absorbs up to 68% of structure-borne noise;

- remains operational at temperatures from -60 to + 90 ° С;

- does not rot, does not undergo mold formation, resistant to chemicals.

The base contains closed air cells, which ensures obstruction for water and heat energy. Good damping characteristics allow the canvas to remain intact even when the log sauna building shrinks.

You cannot simply put the material under the boarding of the walls. It is imperative to make a lathing from a shallow lath, for example, with a section of 20 x 40 mm, under the finishing coating.

Mineral wool with foil

Practical insulation contains mineral (granite, basalt) wool. The material is designed to work in conditions of heat and high humidity. Cotton wool with foil stops convection flows, prevents the spread of infrared radiation.

Characteristics of aluminum polished mineral wool:

- the density of the material is 35 - 45 kg / m³;

- cotton wool can withstand heating temperatures up to + 225 ° С;

- the foil does not collapse in heat up to + 120 ° С;

- chemically inert material.

The insulator is sold in rolls, mats, plates, the layer thickness is 20 - 100 mm. Not all foil wool is suitable for the bath, but only the one whose fibers are treated with special impregnations to increase the hydrophobic qualities. Use means that, when heated, do not emit toxic components into the surrounding space of the steam room.

Use types of foil film for baths based on mineral wool:

- ISOVER Sauna

- ROCKWOOL Sauna Butts.

For fixing, self-adhesive tapes are used, knitting wire, nails, as well as mounting nails are used.

Other types

Foil polystyrene foam is produced with one-sided or double-sided processing. The material can withstand from -170 to + 170 ° С. In the bath, they are often sheathed with a ceiling or placed in a warm water floor, if a concrete lower base is provided in the steam room. For insulation, a material based on expanded polystyrene with a density of 35 kg / m³ is used, since low-performance canvases are destroyed by the constituent components of the concrete mixture.

Foil on a paper basis for a bath is called kraft foil, foil paper, Izolar, Alukraft. A polyethylene film is added to the combined composition of the insulation, which protects the paper base from moisture. According to the technology in the bath, the material can be fixed on the buried surfaces of walls made of timber, logs without installing additional heat-insulating sheathing.Foil paper for a bath is produced with a thickness of 0.03 to 1.0 mm and can withstand heating up to + 100 ° C.

Fiberglass mesh (three-layer folar) includes a 4 x 4 mm honeycomb fiber reinforcement layer that is sandwiched between two layers of aluminum foil. This addition allows the material to work at temperatures from -60 to + 270 ° C. The coating does not contain allergens, carcinogenic substances, elastic, works well for bending, therefore it is used to sheathe the walls of the bath.

Rolled base foil is produced in the form of a thin film (0.007 - 0.2 mm), which does not work well for tearing. They are sold in rolls with a length of 10 to 20 m, a width of 1.0 - 1.5 m. In vertical structures of a bath, base material is glued over a standard insulator against cold. The material can withstand up to + 650 ° С, the reflectivity remains at the standard level (97%).

Sauna heater selection criteria

Determine the required thickness of insulation for a bath building in accordance with the thickness of the wall and the type of material for its construction. Depending on this, they choose, you need to install only a foil insulator or use an additional other type.

Selection criteria:

- brick, concrete with a thickness of 350 and more will require insulation with a thickness of 80 - 100 mm;

- concrete, brick 250 - 350 mm - insulation 100 - 150 mm;

- blockhouse made of wood with a thickness of 100 - 150 mm - insulation 60 - 80 mm;

- log wall 150 - 200 mm - cold insulator 40 - 60 mm thick;

- wooden blockhouse thicker than 200 mm - insulation 20 - 40 mm.

The indicators are applicable only for bath walls, taking into account that a foil layer will be used, which is directed towards the inside of the steam room. The best way to reduce heat losses would be the use of a combined combination of foil insulation and traditional expanded polystyrene, glass wool.

The use of foil for warming baths

The use of flexible canvases with a reflective film reduces the amount of fuel in the bath room, since it serves as a kind of mirror for sending heat rays from the archway back to the steam room.

It is believed that the finishing wall cladding reduces the effect and the foil for the steam room does not do its job. The approval does not work, because the lining reduces the percentage of reflection, but its reverse side near the foil heats up, and the cladding made of natural material becomes less heat conductive. The design of the thermos is changing, but the energy-saving result remains.

Heat-reflecting film evenly distributes the heated air over the plane of the clean skin and on the surface of objects, therefore, the cooling of the room slows down.

Features of the choice of a foil layer

On sale there is insulation based on expanded polystyrene foam, on top of which there is aluminum spraying. Such a metallized layer cannot reflect infrared radiation, does not work as a protective shield. It cannot be purchased for installation in a bath.

Roll types of glass wool of small thickness (10 - 40 mm) are well suited. They are glued to the plane of the wall or laid in the cells of the frame. In the first case, vertical slats are stuffed on top of the isolon for attaching natural lining or decorative boards.

For floor insulation, solid plates with a foil coating are placed, glass wool with an aluminum layer is chosen on the walls. Select the type to withstand at least + 100 ° C.

Coating installation

Before fixing the foil in the steam room, study the features of the installation of this material. Be sure to provide effective ventilation to prevent wetting of the finished wall cladding.

Other installation tips:

- correctly set the minimum ventilated gap along the entire plane of the wall;

- ensure the sealing of the insulator joints so that moisture does not get inside;

- the gaps between the rail and the foil are sealed with polyurethane foam;

- baseless foil without insulation can be placed on log walls, it is fixed with a stapler or staples;

- tears and damages are sealed with tape.

Neglect of even one of the rules leads to disruption of the functioning of foil insulation. Purchasing and installation efforts will be wasted and energy ray reflections will be reduced to zero.