Profiled sheet is a multifunctional material for construction, which is used for different purposes. Modifications are made that differ in the type of coating, size and pitch of the wave. The shape of the corrugation is wavy and trapezoidal. The thickness of the profiled sheet for the fence is required to be minimal, and the wave has a U-shaped appearance, since the fence does not carry loads, except for the action of the wind and its own weight.

- What is a professional sheet

- Advantages and disadvantages of corrugated board

- The main parameters of the profiled sheet for the fence

- How to determine the parameters of the fence

- Varieties of coatings for corrugated board

- How to choose the thickness of the material

- Differences in marking sheets

- The color of the corrugated board for the fence

- Recommendations for choosing a quality professional sheet

What is a professional sheet

Facing, roofing and structural materials have been used in the construction of fences for a long time, while the popularity of filling is only increasing. Metal sheets are produced from steel by cold rolling on bending machines.

The material for fences, gates in the country and in private houses is made of a small height, which gives significant savings due to the lack of cutting to size. Wall varieties that are used for sheathing fences are produced painted on both sides.

In the process, the material is profiled (they give waviness of various shapes). This surface shape gives the sheets additional rigidity and strength.

Raw materials for production:

- galvanized metal in a roll;

- coiled steel with a spraying in the form of a polymer layer;

- aluminum sheets with a decorative layer.

Metal profiles in rolls are supplied by South Korea, England, China, Slovakia, Ukraine, Germany. The automated line profiles sheets 1.25 m wide, 0.4 - 1.5 mm thick. The unwinder drum feeds the plates to the rolling mill, where cutting is performed using a hydraulic cut-off knife. The formed sheets are fed to the receiving table for further cycle.

They produce types of corrugated board for a fence with increased resistance to ultraviolet light, while the color does not fade. This material is highly resistant to corrosion.

Advantages and disadvantages of corrugated board

To understand which professional sheet is better to make a fence, you need to study the general characteristics of the material.

Advantages of using a profiled sheet for sewing fence sections:

- quick and easy installation, long sheet length (up to 12 meters);

- surface corrosion protection;

- variety of colors, attractive appearance;

- light weight.

The profiled sheet weighs a little, so the construction of the fence does not imply the device of a strip base, such as under a stone fence. Only the pillars are dug in and concreted. The steel under the layers of zinc and polymers resists collapse, since moisture does not enter it.

The coating is made in different colors and patterns. Profiled steel sheets imitate a fence made of various types of wood, natural stone, so each fence can have a different appearance and complement the architectural solution of the courtyard and facade.

The disadvantages include the increased sound of the material when raindrops hit, but such a disadvantage manifests itself when the roof is installed, and does not really matter for the fence. The second disadvantage is the loss of corrosion resistance if the protective layer is damaged. All types of corrugated sheets for a fence can be cut with a circular saw; it is not recommended to use a grinder. The circle breaks the integrity of the coating at the cut.

The main parameters of the profiled sheet for the fence

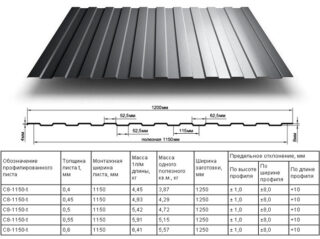

The length of the sheets can be changed and adjusted by the customer, but the width always depends on the size of the wave in height. Better for a fence corrugated board with fine profiling. Wall varieties include material with a corrugation height of 8, 10, 15, 20, and 21 mm.

The corrugated board for the fence experiences the "sail effect", therefore, for its attachment, a reinforced frame is made or an optimal wave height is taken.

Dependence of the useful and total width depending on the height of the corrugation:

- height 2.5 mm - useful width 1200 mm, total - 1240 mm;

- 8 mm - respectively 1150 and 1200 mm;

- 10 mm - 1150 and 1190 mm;

- 20 mm - 1080 and 1130;

- 44 mm - 1010 and 1080 mm;

- 57 mm - 965 and 1025 mm;

- 60 mm - 860 and 930 mm.

The calculation of the required number of sheets is carried out according to the useful width. The most popular is the length of the metal profile 1.8 - 2.0 meters, so manufacturers produce the material according to the application standard.

Which professional sheet to choose for the fence depends on its weight. The weight of the sheets depends on the thickness of the rolled product. One running meter of the widespread brand HC 35 x 1000 with a thickness of 0.6 mm weighs 6.4 kg. Increasing the thickness to 0.7 mm increases the weight to 7.4 kg, and sheets with a thickness of 0.8 mm weigh 8.4 kg.

How to determine the parameters of the fence

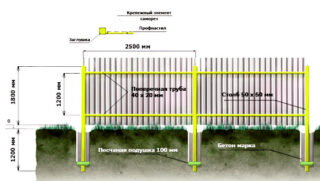

For the fence, you need a corrugated board that will organically fit into the parameters of the future fence, therefore, the arrangement of the pillars and the length of the sections are drawn on paper in the form of a sketch in order to visually see the need for material.

Recommendations for the size of the fence:

- a fence is made in height, taking into account the height of a person (175 - 180 cm) plus 15 - 20 cm;

- the width between the supports is 2.5 - 3.0 m, so as to rationally use the pillars and prevent overspending of metal pipes;

- 2 posts are added to the installation of the gate, and double elements of turns are also taken into account, if necessary;

- the length of the pillars is chosen so that they are in the ground at a depth of 200 - 400 mm, and the tops should not protrude above the edge of the corrugated board.

If the height of the fence is up to two meters, one transverse piping is placed around the perimeter, a sewing height of more than two meters requires two transverse rows of pipes. For 1 square of corrugated board, 4 - 8 hardware is calculated for fixing.

Varieties of coatings for corrugated board

For a fence, it is better to have a profiled sheet that will resist weathering and will not rust from corrosion. Sheets are galvanized, with a double-sided and one-sided coating layer on the surface.

Types of coatings:

- Polyester, layer thickness of about 25 microns, resulting in a semi-matt smooth surface. The coating does not increase the cost of the material too much, it is popular in use.

- Textured polyester is 25-45 microns thick for durability. The coating has an attractive appearance.

- Plastisol. The coating material is applied in a layer of 100-200 microns, which distinguishes the corrugated board from other types. They are used for fences, since the profiled sheet is characterized by high resistance to corrosion.

- Polyurethane. Creates a textured semi-matt film on a plane, which is more environmentally friendly compared to other layers. Withstands severe frosts and summer heat.

It is better to choose a profile for a fence with a PVDF layer on the surface. The acrylic and polyvinylidene fluoride coating resists damage from ultraviolet radiation and mechanical shock.

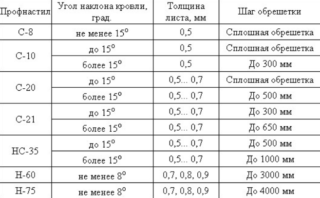

How to choose the thickness of the material

For fences, the optimal thickness is chosen, which will allow the material to be mounted at an affordable price, while the material will last a certain time without changing its qualities. The thickness of the corrugated board for the fence is taken without taking into account the decorative coating and the paint layer on the surface.

Recommendations for the use of sheets of different thicknesses:

- size 0.35 mm is used for temporary fences around construction sites, in areas protected from strong winds;

- a thickness of 0.4 - 0.45 mm is set to separate private yards, summer cottages, plots and industrial areas, a common and popular size;

- thickness greater than 0.5 mm is suitable for installation in open areas, high places where winds blow.

The thickness of the sheet and the height of the profile are dependent. If the wave parameter increases, the thickness can be taken less. Also, the choice of parameters is influenced by the number of transverse support bars.

Differences in marking sheets

For the construction of fences, sheets of a certain marking are taken. Letters and numbers show the width and thickness of the corrugated sheet.

Decoding of designations, for example, С8-0,50-1100-12000:

- different letters speak of strength, the letter H speaks of the bearing category, letter C indicates belonging to the wall group, NS - universal application;

- the number after the letter indicates the height of the wave, in this particular case - 8 mm;

- the second speaks of the thickness of the sheet - 0.50 mm;

- the third indicates the panel mounting width (1100 mm);

- the last number is the length of the sheet.

To sew the spans between the posts, use sheets marked with the letters C and HC.

The color of the corrugated board for the fence

Profiled sheet with colored coating has different shades. To choose the color of the future fence, use the RAL catalog. It has been used since 1927 in the production of paints, varnishes, building materials, where it is important to choose the right color.

Shades are denoted by numbers:

- 1 - yellow;

- 2 - orange;

- 3 - red;

- 4 - purple;

- 5 - blue;

- 6 - green;

- 7 - gray;

- 8 - brown;

- 9 - white and black.

The catalog helps to select and order accessories for the design of the corrugated board of the desired shade so that there is no difference in color against the background of the material. When choosing the color of the fence, the outer part must be made darker, and the inner part must be left light.

A combination of two colors is common so that too large and long designs of fences do not look boring and monotonous. Most often, green colors are taken for fences, which fit well into the landscape, combined with the walls of the house.

Recommendations for choosing a quality professional sheet

The material is selected from a well-known manufacturer, whose sheet quality will correspond to the declared characteristics. There are species that are produced by the artisanal method, so such products are not of a better quality.

Responsible manufacturers and their dealers always provide buyers with competent advice on the use of a particular type of profiled sheet, the quality of various types of coating and other parameters. Large manufacturers will not hide the thickness of the raw steel and zinc spraying.

The cost plays an important role when choosing a professional sheet for the fence. For the best price-quality ratio, you need to consider offers from different representatives so as not to make a mistake in your choice. Sometimes it is more profitable to purchase material directly from the manufacturer. When comparing prices, the distance of the warehouse location and the cost of delivery to the place are taken into account.