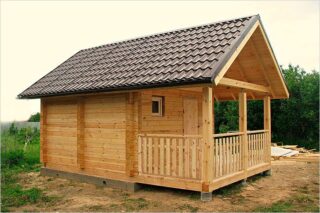

The walls of the bath experience temperature changes, they are affected by moisture and internal steam. When choosing materials for external cladding, take into account resistance to these factors, durability and strength. The outside cladding of the bathhouse should be combined with the style of the building and the surrounding landscape, and should be inexpensive. The cladding technology is simple, so that the owner can sheathe the facade with his own hands.

What is the lining of the bath for?

A new building made of bricks, wooden beams or logs does not require external cladding, as it looks beautiful. Over time, the wood darkens, becomes unattractive, begins to deteriorate from weather factors. The brick surface is also aging, the mortar in the seams cracks, falls out. To update the facade, modern materials are used that emphasize the individuality of the building.

If the bathhouse is built from a foam block, cinder block or aerated concrete, the structure must be finished immediately, since the stones have a gray and boring look, such a building will not be able to decorate the site. Foam concrete is characterized by increased resistance to moisture, which cannot be said about aerated blocks. This wall material requires external waterproofing against rain, which is always combined with different finishing options for the bath outside.

As a result, it becomes possible to set layers:

- heat insulating material;

- waterproofing pad;

- windproof film;

- soundproof membrane.

Sheathing on a frame made of slats or profiles helps to solve the problem of thermal insulation of the outer surfaces of the walls. The task of the outer cladding is to obtain the effect of a thermos; without this result, the bath will not provide the required functionality.

Materials for exterior decoration of the bath

The material for work is selected so that it can provide external attractiveness and make it possible to apply insulation. Finishing layers are suitable, which are mounted like a curtain facade on a crate. This technology makes it possible to combine the cladding with insulating materials.

The outer version of the cladding saves usable space from the inside of the bath; the types of finishing layers are used for work:

- siding;

- tiles made of natural or artificial stone;

- wooden cladding with a board;

- facade metal corrugated board, plastic;

- lining for outdoor use;

- block house with imitation of logs.

There is also a wet processing method. Modern plaster is called warm, because layers of foil-clad foam, polyurethane foam, and polystyrene are placed inside. On their surface, a plaster mesh is glued, then finishing layers are applied. They make a simple smooth surface for painting or create a decorative surface with imitation of various textures.

Vinyl siding

Siding is used for brick, foam concrete, aerated concrete surfaces. Wood wall structures need to breathe, and vinyl material does not create this effect. To obtain a ventilated gap in the finish, use the counter-grill installation method.

Positive qualities of the material:

- withstands the temperature range from -50 ° С to + 50 ° С without loss of quality;

- vinyl siding contains modifiers that strengthen the color, so it does not fade in the sun;

- serves for up to 40 years, is easy to clean, washable, non-toxic.

The panels are produced in various colors and shades, it is possible to obtain a surface with an imitation of natural stone, expensive wood species. It is placed horizontally or vertically. The supporting frame for siding is made from a galvanized profile from a drywall system or wooden slats are used.

For the installation of siding, you will need docking elements that are supplied with the base material and correspond to the selected color. For fastening the strips, corners, initial, final and window strips, basement drains and various brackets are used.

Slab materials

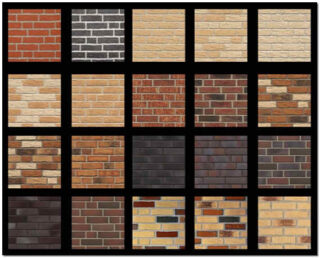

The advantage of facade tiles is reliability and durability; such a finish will last a long time and protect the surface of the walls from destruction. On sale there is a variant of facade elements with fastening plates for ease of installation. Galvanized parts are used for fastening to the frame with self-tapping screws.

Pros of using ceramic tiles:

- the material does not burn, does not emit harmful substances during heating, belongs to the category of environmentally friendly finishes;

- differs in a quite acceptable cost;

- a wide range of textures, patterns and colors;

- does not fade over time, firmly endures changes in heat and cold;

- fast veneer.

The lath tile finish evens out the wall surfaces. If the ceramics are dry-mounted on the frame, a ventilated space is obtained for the installation of a thermal insulation pad. Mount the material from the bottom corner, then put it in horizontal stripes. The first tile in a row is fixed with four self-tapping screws. For the next one there is a groove in the form of a lock on the previous element, so 2 hardware is enough for it.

Before sheathing the bath outside with ceramics, it should be remembered that the installation of the frame and the hinge of the tiles can be done only after the structure has completely shrunk, for which a period of 1 year is approximately calculated.

Wood cladding

The outside walls of the bathhouse can be finished with a board. To do this, take edged or unedged sawn timber with a thickness of 10 - 15 mm, a width of 100 - 150 mm. For exterior decoration, coniferous species are used, since the material resists moisture well. The covering from the boards requires preliminary treatment with antiseptics against microorganisms, preparations against rot, mold. Impregnation is used against the rapid ignition of wood in a fire.

Quality characteristics of wood cladding:

- environmental safety of the material;

- availability for purchase, low cost, quick installation;

- resistance to damage, exposure to an aggressive environment (in the case of processing);

- beautiful appearance;

- a variety of species used for decoration;

- good insulation from the cold;

- the duration of operation with regular treatment with antiseptics, varnishes, paints (approximately once every 2 years).

The log house is sewn up horizontally to increase resistance to deformation and moisture ingress. The board is sewn directly onto even walls or the surface is leveled using a rack frame. Before installation, the lumber is sanded.

Warm plaster

The technology is used for finishing stone, block buildings, and is also used for wooden and frame walls. Traditional is a cement-sand mortar, but in modern conditions, modified ready-made dry mixes are used, which are dissolved with water before application.

There are formulations with fillers that create a relief pattern on the surface. A convex ornament is used with the help of crumbs of marble, granite, quartz, dyes and pigments are added. Then the area can be decorated with latex or oil paints. Plaster is combined with tiles, brick cladding.

The layer is warm, since first, slabs of insulation are glued to the surface of the wall, which is covered with a mesh, then plastered. Insulators are used that are highly hydrophobic, i.e. do not absorb water.

The advantages of the coating are its low cost, beautiful appearance, the ability to do the work with your own hands. The disadvantage is that the coating is heavy and loads the vertical coverings and the basement of the bath. The work takes a certain amount of time, since it is necessary to maintain the intervals for drying the primer, intermediate layers of the solution.

Facade panels

For finishing the bath outside, profiled flooring and plastic are used. The professional sheet is produced in the form of wide strips, on the surface of which there are waves of a certain size and shape. For installation, use wall types of corrugated board. The material is lightweight, easy to install, available in different colors and patterns.

The profiled sheet is produced in widths from 0.9 to 1.3 m, which speeds up the work. It is placed on a frame, so the finish is combined with insulation. The polymer coating of galvanized metal additionally protects the material from negative weather factors.

Plastic is also mounted as a finish; thick panels (from 10 mm) are chosen. The material has a low cost, does not rot, does not deteriorate from corrosion. The strips do not need to be treated with antiseptics, they tolerate frost and heat well, but ignite in a fire, the surface suffers from mechanical damage.

Lining for external work

Refers to budget cladding options, which looks good as a wall material on the facade. When choosing, take into account the moisture content of the lining, which should not exceed 16%. The raw material will dry out and there will be gaps between the elements. Boards are taken up to 150 mm wide, and their length is 3.0 - 6.0 m, which is beneficial for obtaining waste-free cutting.

For the bath, natural coniferous lining is used or MDF material is used. The second option is a product made up of wood processing residues. Fastened to each other in the groove-thorn type. The glued panels are characterized by minimal deformation and shrinkage.

Lining on the basis of MDF is distinguished by higher qualities in terms of operation compared to panels made of natural wood. On sale there is a profile with a different design of grooves, convexities on the surface, roundings. The panels have ventilation grooves on the back to prevent rotting.

Finishing the bath outside with a block house

The material is a type of lining of a higher cost with improved qualities. The finished surface looks like a round log of different sizes. Also pay attention to moisture when buying. You do not need to purchase raw and overdried material.

A block house is made from a log, while the central part is cut into boards, and the edge wane goes to the lining. Sometimes cladding is obtained by milling edged boards from four sides.

Depending on the quality, classes are distinguished:

- Extra;

- A, B, C.

The block house is mounted on a prepared surface. It can be a wall itself or a mounted frame. The cladding is placed from bottom to top, attention is paid to leveling the first board. For external cladding, the strips are mounted with the groove down to prevent water from flowing in the rain.

Features of the external design of the bath

To make the boards and lining look more solid, they are tinted with stain and varnished. Compositions based on ethylene glycol are used, the surface is coated in several layers, depending on the desired effect. Not all breeds require refining, for example, larch, birch, pear, apple are distinguished by a beautiful pattern, their cut is only covered with three layers of varnish.

Exterior decoration includes:

- arrangement of cornices;

- opening finishing;

- plinth trim;

- facing of the pediment.

For these works, materials similar to the main covering layer are used, or combinations of combining types are used. For wooden walls, carved elements are used, which are placed around windows, doors, on the ridge of the roof. The gable in front of the cladding is also insulated from moisture and heat loss.

The plinth is often made with a material that creates visual solidity as a plinth. For example, they use siding, corrugated board with a pattern of natural stone, while the walls at the top are trimmed with material with imitation of wood, they put a block house, lining.

External insulation

The wooden blockhouse needs to be caulked constantly to keep the walls warm. An analogue is external and internal insulation, in order to forget about such processing of seams for many years. Energy conservation plays an important role in fuel economy. It takes less time to warm up the steam room, as well as to maintain the required temperature.

If you do not make the outer cladding, there is a danger of constant condensation on the internal surfaces in the steam room due to the temperature difference inside and outside during winter. Drops lead to the destruction of the finishing layers, spoil the wood paneling of the walls. Perspiration falls on the floor, creating additional moisture, which must be removed so that the coating does not slip underfoot.

Exterior decoration with insulation contributes to the establishment of standard microclimate indicators inside the steam room.