Motorists will always have a motor oil that has worked out its life. It is rational to use the used substance for heating the garage, shed, utility rooms. The owners of houses, plots that have a car, make a working furnace with a water circuit with their own hands. Sometimes they assemble the structure without connecting the line, put models with supercharging or drip oil supply.

- What is working off

- The scope of use of a homemade furnace for working out

- General principles of oven operation

- Varieties of working furnaces

- Waste oil pyrolysis furnace from a gas cylinder with a water circuit

- Homemade stove with forced ventilation

- Waste furnace from an old gas cylinder

- Supercharged working furnace

- Working furnace with a water circuit

- Drip-fed stove

- Sizing calculation

- Fuel consumption and economic feasibility

- Materials for making

- Pros and cons

- How to make a stove for working off with your own hands

- Security measures

What is working off

A run-off is engine oil that was previously used when the machine's engine was running. It lubricated the undercarriage and engine parts. In the process of use, the pure product of the distillation of oil is saturated with impurities of metal particles due to friction, salts, resin, soot. A waste product is not suitable for lubricating auto parts, but the substance burns well.

The oil used is good for lighting a fire, keeping the flame in the hearth. During combustion, harmful gases and volatile components of heavy metals, lead, zinc, manganese are released into the air, therefore, they do not take work off for a barbecue, a brazier. World practice shows that such a product is ideal as fuel for an oil-fired stove.

The scope of use of a homemade furnace for working out

When burned, used oil smells strong and unpleasant, the vapors are harmful to health if inhaled regularly. Carbon deposits and soot will invariably appear on the walls and ceilings. Because of this, an oil-fired oven is not used in a residential building.

An exception is the case when there is no other heating option. In this case, it is necessary to make an ideal system of forced ventilation of the room. In auxiliary and non-residential buildings, such heating devices are allowed to be installed.

Even a simple potbelly stove for working off with your own hands allows you to coordinate the burning rate of the oil mass, so all models are economical to work with. You can configure the unit to gradually heat up the air or provide the fastest possible warm-up.

General principles of oven operation

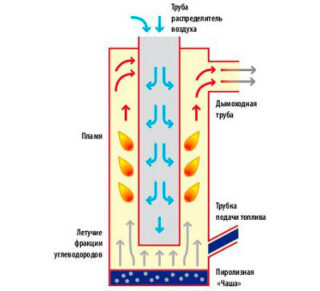

The oil itself does not burn, but fumes, therefore, the principle of ignition of the vapors that are released is used.

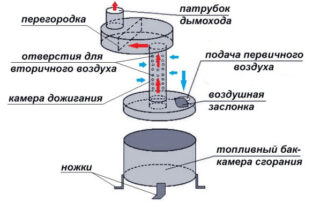

The construction requires nodes:

- tank for heating the oil mass;

- air supply system;

- afterburner compartment.

Up to 2/3 of the cubic capacity is poured into the fuel chamber. After settling, a sufficient volume of vapors is formed, they are ignited with a torch. Use a smoldering oiled rag, a torch. After that, the door is put in a closed position, do not open until the fuel burns out.

The evolved vapors also enter the afterburner, where they burn together with oxygen with a large release of heat. The process is regulated by dampers. The firebox and afterburner are of the same size. With the correct design, a blue-white flame appears.

Varieties of working furnaces

Waste oil pyrolysis furnace from a gas cylinder with a water circuit

Prepare two containers, which are connected with a perforated pipe. The lower one contains oil, here it is set on fire. Working out in the upper cylinder burns out, the temperature is regulated by reducing the intensity of vapor supply to the afterburner compartment.

Homemade stove with forced ventilation

A fan is built into the unit, which moves the air into the afterburner. It turns out more efficient combustion, uniform heated streams go into the room. Some models provide automatic control of fan start and stop.

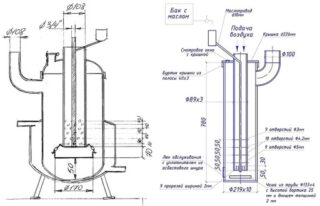

Waste furnace from an old gas cylinder

For manufacturing, take a cylinder with a cubic capacity of 50 liters. Tanks of Soviet models for storing propane work well. You can take oxygen, but it is more massive, it is more difficult to alter it.

For greater efficiency, a heat exchanger is assembled. A simple option provides for iron plates welded to the cylinder body in a specific order. For filling oil, a hatch with sealed doors is made.

The efficiency of furnaces made from a cylinder varies in the range of 85 - 90%. This is a good indicator in comparison with other homemade hearths for space heating.

Supercharged working furnace

The air supply is organized using a built-in turbine; it can be used from the furnace heating system of a VAZ car.

The air blowing device is selected with heat-resistant characteristics so that it does not deteriorate after several refueling of fuel. The chimney is made from a pipe with a diameter of 100 mm, it is welded at the top of the second cylinder, having previously formed a hole under the branch pipe. The inner walls should be smooth to reduce the deposition of soot and grime.

In pressurized units, the burner flame deflects and heats one place on the body, so it can burn out in this area.

Working furnace with a water circuit

A water heating circuit is connected to a self-made unit, which passes through adjacent rooms and heats them. A metal water tank is installed on the upper surface of the furnace, and the liquid is discharged into the system using a connecting pipe. The return circuit returns the used water to the tank.

An open and closed heating main is installed. For the first option, an expansion tank is needed to compensate for the thermal expansion of the pipes. The joints of the pipes with each other, with the walls of the water tank are hermetically welded or a threaded connection is used.

Drip-fed stove

A safe option compared to oil cylinder ovens, when the entire mass is loaded in one go. The fuel supply is coordinated more precisely, so there is a possibility of an even increase in temperature. A separate fuel tank is required, where the unused mining is located.

Drip oil supply is carried out using an automatic device. An oil pipe is laid between the fuel tank and the combustion chamber. The flow rate of drops is controlled by a valve.

The disadvantage of the dropper oven is the complexity of the design, which novice masters cannot always perform. The design is selected for specific conditions, so there may be several modifications. As a result, an economical furnace is obtained with a low consumption of oil fuel.

Sizing calculation

The volume of the firebox is found taking into account the quadrature of the room. Normally, about 500 watts are required for each square of the floor. The calculation involves correction factors that take into account the material of the walls, floors, the area of windows, doors, the average annual temperature in the region. The multipliers can be found in special tables for heating constructors.

The resulting value of the required energy and fuel consumption of a particular stove are used to find the volume of the firebox. More often they take a volume of 10 - 20 liters.

Fuel consumption and economic feasibility

The consumption, depending on the design and dimensions of the furnace, is approximately 1 - 2 liters per hour, while heat is released in the amount of 11 kW / hour for each liter spent. The components of the mining are burned by 85 - 90%. Used engine oil can be compared to diesel fuel in terms of efficiency.

Clogged mining works worse, in which solid particles, salts and other components are present. Such compositions are filtered before pouring into the oven. Consumption can be reduced if the unit is regularly cleaned from soot on the walls of the cylinder, at its bottom.

Materials for making

Take two gas cylinders to make a two-chamber installation with a vapor afterburner.

Materials required:

- metal sheets with a thickness of 6 and 4 mm. The dimensions depend on the dimensions of the stove, the details are in the drawing;

- iron pipe DN with a cross section of at least 100 mm, a length of 2 meters;

- fan;

- nozzles;

- bolts with nuts or studs not less than M12, washers for them.

For work, they prepare a grinder, welding, a drill, a device for bending metal into a cylinder.

Pros and cons

Used oil costs nothing to the owner of the car, and if it is not enough, fuel can be purchased at a cheap price. This type of heating is classified as an economically viable option.

Other benefits:

- the efficiency is comparable to the work of a medium power electric fireplace;

- operation is simple, does not require special training;

- the heating unit is assembled, if desired, independently from improvised and inexpensive elements.

The disadvantages include an unpleasant odor and the release of harmful substances during combustion.

How to make a stove for working off with your own hands

The container is freed from condensation, rinsed with water. The top of the cylinder is cut off at the mark, left for the manufacture of the cap. From the bottom of the container, a support is welded for stability from the corners.

A hole is drilled 10 cm from the top for the smoke to escape, a 40 cm bend is placed in it, where a plumb pipe about four meters high is welded and taken out of the room.

The metal is cut according to the dimensions of the drawing to assemble the casing, box, afterburner. If the afterburning compartment has a bend at the top, the pipe end is formed at 45 °. The cover is made of sheet steel.

In the fuel compartment, two holes are cut out for the outlet of vapors and for refueling with oil fuel. The pipe from the firebox is joined with the branch pipe of the afterburning compartment. Holes are made in the pipe in three rows with a diameter of 8 - 9 mm. A damper is made of steel to coordinate the air supply.

Security measures

During operation, the condition of the unit must be regularly checked. Joints, welds, bolted joints are sealed, and the room must have an inflow of fresh air. Sharp drafts that cause strong flames or torch detachment are not allowed.

During combustion, water should not get into the oil so that the burning oil is not ejected onto the surrounding objects and people. Any malfunction in operation requires stopping the unit and finding out the reasons. There must be a fire extinguisher in the coverage area.