For a residential building to be comfortable, durable and beautiful, a competent choice of facing material is important. House cladding with brick siding is an excellent option. The decoration faithfully imitates masonry and serves as an excellent protection of the building from external factors. In order not to be mistaken with the choice, you need to understand the features of the panels on sale and the rules for their installation.

Varieties of siding for outdoor decoration

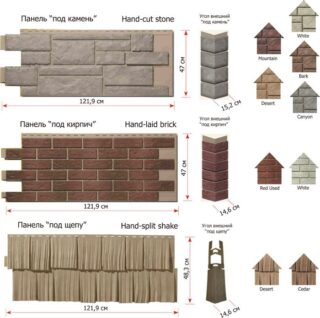

Manufacturers produce siding for the exterior of a house under a brick with a matte and glossy texture, with stones painted in white, red, gray and even beige. Quality models look so natural that imitation can only be recognized by close examination.

On sale are panels made of the following materials:

- Wood. Moisture-resistant breeds are mainly used - oak, larch, cedar. Spruce and pine are deeply impregnated and several lamellas are glued. The surface looks quite natural, but requires periodic restoration.

- Metal. The production of the coating is carried out by the method of cold rollers, followed by galvanizing and polymer spraying. The material is durable, resistant to external factors and fire safety. The disadvantage is the heavy weight, which implies additional stress on the walls and foundations. Also, fastening the sheets is fraught with certain difficulties.

- Vinyl. Real brickwork serves as a template for manufacturing. Thanks to this approach, the finished cladding has all the characteristic features of a brick wall. All small details are clearly visible on it - cracks, seams, roughness. The material is durable, resilient, easy to install and serves for decades.

- Fiber cement. It is a mixture of powder, water and cellulose fibers. Raw materials are heat-treated, in the finished form the plates acquire strength, fire resistance, resistance to moisture, ultraviolet light, temperature extremes.

Plinth panels can be distinguished as a separate direction. This part of the building is exposed to the strongest external and internal loads, therefore, a material of increased thickness and increased strength is chosen for its decoration. As a rule, the color and texture of such products does not differ from standard wall counterparts.

Advantages and disadvantages of siding

A house clad with brick siding looks natural, expensive and presentable. This choice is based on the following advantages of the material:

- Presentable appearance. Modern technologies provide a natural surface that sometimes looks even better than the original.

- No need for care, maintenance and repair. Panels only need to be washed and dust-free from time to time. Damaged fragments can be easily replaced.

- Resistance to external factors. The addition of special additives makes the coating impervious to dampness, insects and animals, cooling and heating.

- Long service life. Manufacturers give a 30-50 year guarantee for their products without any restrictions on operating conditions.

- The ability to decorate the house with siding with your own hands without the involvement of hired workers. The procedure is quite simple and does not require the purchase of special equipment.

- When using frame technology, the developer receives a closed space that can be used for hidden laying of communications and placement of thermal insulation.

- Affordable cost. House cladding under a brick is much cheaper than massive monolithic stone masonry.

- Lack of reference to the warm season. You can sheathe buildings with siding at any time of the year.

- A wide selection of materials, colors, textures and sizes, the presence of additional elements.

The main disadvantage is limited strength. No type of coverage will be able to resist intruders. A guarantee can only be a reliable base to which the finish is attached.

Dimensions of brick siding

Siding models made in Russia, Europe and Asia are on sale. The choice is wide, thanks to which the developer can choose the most optimal option for himself.

It is worth focusing on the following parameters:

- length - 1840-2060 mm;

- height - 210-240 mm, with a fastening edge add 50 mm;

- thickness - 0.8-2.5 mm.

Fastening of panels is carried out in side locks, which have a broken or even shape. From above, the parts are connected according to the thorn-groove principle. The joints are not airtight, but the joints are not visible. There is a feeling of real brickwork.

Siding selection rules

When choosing an imitation brick for the exterior of a house, one should not be guided by its cost. The cladding is done for many years and all this time it should serve properly, pleasing the eyes of residents, without giving them the hassle of maintenance and care.

When buying a product, you need to pay attention to the following details:

- Availability of accompanying documents. For quality goods, there are certificates and a waybill, indicating its origin.

- Completeness. The planks should be accompanied by corners corresponding to them in size and color.

- Integrity. Scratches, chips, cracks on slats and locks are excluded. Products must be flat, without distortions and deformations.

The calculation of the need for finishing can be done according to the ratio of areas or schematically, applying each detail to the diagram. In all cases, you should purchase the material with a margin of 10-15% based on its damage during transportation and installation.

Do-it-yourself outdoor home decoration technology

Siding installation presupposes the availability of such tools and materials:

- roulette;

- level;

- puncher;

- a hammer;

- screwdriver;

- scissors for metal;

- saw for metal;

- paint brush;

- marker;

- PP profile 60/27 mm for the frame;

- marker;

- insulation.

The work is carried out in the following sequence:

- Preparing the walls. Filling up cracks, removing nails and screws, grinding off protruding fragments, treating the surface with an antiseptic and hydrophobic primer.

- Installation of the frame. First, the markup is done. Then, every 60-80 cm, holes are made, dowels are inserted, suspensions are screwed on. Finally, the vertical and transverse profiles are fixed.

- Installation of insulation. The best option is to glue it to the wall, followed by fixing with dowels at five points.

- Installation of the bottom ebb and start strip, corner and dividing profiles. Securing locks on the guides.

- Installation of the first and subsequent cladding elements. First, docking is carried out into the lock, then the panel is screwed to the frame through the mounting plate.

- Fitting the finishing profile. This is done when attaching the last plank in the masonry.

- Installation of a drainage system. Covering window and door slopes with pieces of siding.

- Sealing joints. For this, a facade sealant is used.

In conclusion, the quality of work is checked, flaws are eliminated. The remaining material is put away for storage.