Brick house is a reliable, practical and durable construction. But no matter how excellent the building stone is, it must be protected, especially in areas with severe weather conditions.

Requirements for finishing a brick house outside

Not all possible finishes are suitable for facing brick facades. Their purpose is to protect walls from rain, snow and wind.

Requirements for finishing a brick house:

- Resistant to moisture. Porcelain stoneware or clinker are low porosity materials. Sheathing with such a stone does not absorb moisture and does not let it through to the brick walls.

- Repairability - if the entire facade needs to be disassembled to replace a damaged defect, this option is difficult to consider as successful.

- Decorativeness - they decide to sheathe the facade in order to give it a beautiful look.

Finishing also solves minor problems, for example, braves rodents and insects, allows you to additionally insulate the house.

Plating options

The finish is chosen for its attractiveness and moisture resistance. The latter is important for buildings made of porous materials, like sand-lime bricks.

Tile

- Clinker - differs from brick in small thickness, but has other advantages of clinker. The material does not absorb moisture at all, is not afraid of the most severe frosts or heat, and is resistant to aggressive chemicals.

- Terracotta tiles are durable for me, but they are also moisture resistant and are not afraid of the most severe frosts. The material looks more like ceramic in color and texture, so it looks interesting on the facade. Ceramics are durable, beautiful, and weigh less. The disadvantage is complex installation.

- Decorative - cement or concrete. The material is lightweight, hard, although inferior in strength to clinker. The main advantage of finishing is a variety of textures and colors. It imitates any natural or artificial stone.

An interesting option is flexible tiles. It is glued to the facade and allows you to change the appearance of the building in a couple of days. However, it does not differ in high moisture resistance or strength.

Thermal panels

This is the name of a building element that includes all layers of conventional cladding: insulation, hydro and vapor barrier and decorative tiles. Some also include an additional backing of refractory material to reduce the risk of fire.

The top layer of the panel is made of clinker, decorative tiles, porcelain stoneware. The assembled panels form a normal wall surface, which in appearance cannot be distinguished from clinker or artificial stone cladding.

Siding

- Metal - steel or aluminum. The lamellas are durable, lightweight, and do not corrode. Steel should be painted and protected from rust. Aluminum does not rust.

- Vinyl - the material is produced both in the form of lamellas and in the form of facade panels. Plastic is lightweight, but provides wind protection, does not allow moisture to pass through, but fears severe cold weather. Vinyl siding imitates wood, stone, ceramics.

- Wooden - made from wood chips, so it is much more resistant to water than lining.

- Fiber cement - not afraid of water, sun, cold, rust. Non-flammable, resistant to mechanical damage.The siding is quite heavy, so the cladding takes a long time.

When decorating a brick wall, only the degree of protection from water and wind that siding provides is important.

A rock

Slabs made of artificial stone weigh much less. In terms of strength and durability, they are not always inferior to natural ones. Porcelain stoneware is stronger and less moisture-absorbing than real. Concrete conglomerates are more fragile, but easier to replace.

Plaster

The simplest finishing option is plastering. Since the facade has a large area, smooth plaster mixes are rarely used - they are too simple. Structural plaster is preferred, which, due to the displacement of the granules during application, forms an unusual relief surface.

Impressive mosaic plaster for outdoor use. This mixture contains small colored stones. The solidified layer is, as it were, formed from them.

Thermal insulation and rough finishing

Insulation from the outside is often a more profitable solution than from the inside. The brick wall and cladding do not prevent this.

There are 2 options:

- Frameless - slab insulation, like polystyrene or polystyrene foam, can be simply glued onto a flat brick surface. Such a wall is easy to plaster, tiled.

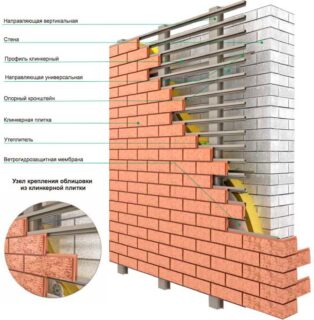

- Frame - for cladding with siding, clapboard, natural or artificial stone, a metal frame is often mounted. Its structure forms an excellent basis for insulation. Plate heat insulators are mainly used, but you can also take mineral, basalt wool.

When sheathing with thermal panels, additional insulation is not carried out. If the house is finished with clinker, all insulation work is done inside.

Required tools and materials

Different methods require a wide variety of materials and tools. The most popular option is siding. For this you need:

- vinyl, metal, wooden slats;

- steel profile;

- self-tapping screws, dowels for fasteners;

- drill, screwdriver, hammer drill;

- metal scissors, hacksaw, hammer, pliers;

- tape measure, plumb line or rule.

Additional materials may be required, such as reinforcing mesh, polyurethane foam.

Finishing technology

Procedure:

- Attach the starting and corner profiles. Then they put the finishing bar. The self-tapping screws are not tightened by about 1 turn to compensate for the expansion of the material.

- A vertical H-profile is fixed according to the marks in increments of 30-40 cm.

- Sheathing begins from the bottom. The panel is inserted into the starting plate, fastened with self-tapping screws to the profile. There is a 5 mm gap between the head and the material.

- The next lamella is inserted into the groove of the previous one, snapped into place, and also fixed with self-tapping screws.

- The last element is inserted into the finishing strip until it clicks.

A wooden crate is not placed on a brick wall.

General rules and recommendations

It is worth choosing the finishing material taking into account the advice of professionals:

- If the weight of the finish is important, the lightest materials are preferred: vinyl and wood siding, plaster.

- If durability is not important, use plastic panels, concrete tiles. plaster. If it is important to protect the walls of the building for a long time, cladding is made of clinker, brick, natural stone.

- With a complex structure of the wall cake, it is important to choose a finish so that its vapor permeability exceeds the vapor permeability of a brick wall. Fiber cement siding, plastering compounds are suitable for this, but artificial stone, clinker or vinyl siding are not suitable.

A brick building is decorated with many different materials. The main criteria here are moisture resistance and decorativeness.