Panel cladding made of vinyl, steel, wood is used to protect wall structures from wind, rain, snow. Siding of a wooden house is done on a frame, therefore, it is combined with the installation of insulation. The material is produced by forcing the raw mass through extruder machines, followed by cutting to size. The panels are distinguished by high consumer qualities.

Varieties of siding for a wooden house

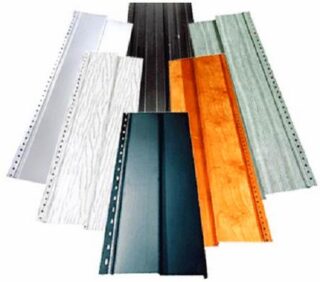

The material is divided into vertical and horizontal according to the type of installation on the facade of a log house. The first type is rarely used in housing construction technology, more often for cladding social and industrial facilities. Horizontal stripes imitate different types of façade finishes, ranging from wood planks to masonry or brickwork.

By cladding a wooden house with siding, the following issues are solved:

- increase the attractiveness of the appearance of the structure;

- extend the life of the house;

- reduce heat transfer from walls.

With the help of siding, they advantageously beat the basement of the building, while the installation is simple and quick. The panels are installed on the frame, resulting in a ventilated facade. The material does not rot, does not absorb moisture, the surface is not interesting to fungi, microorganisms, rodents do not settle inside.

Environmentally friendly siding does not emit harmful components into the atmosphere, and the maintenance of the finish is simple. The surface is washed with water from a hose; detergents are used for dirty places. The damaged panel is replaced with a new one by disassembling and reinstalling.

Basement

For cladding the lower part of the walls, cast facade panels are used, which are made of steel or vinyl. Other materials are used, but they must meet certain requirements, such as impact resistance, abrasion and moisture resistance.

Basement finishes are of high quality and reliability. The plinth is close to the surface of the ground, it is exposed to loads from kicks and other objects.

Negative factors act on the cladding:

- dampness and moisture;

- temperature difference with the outer and inner sides of the foundation;

- dust, dirt, vehicle exhaust.

If the walls of a house made of logs are finished with ceramics, artificial or natural stone, then a plinth with a pattern of a wooden board will look weak. The basement material is often chosen with an imitation of stone, brick, so that the pedestal of the house looks reliable.

Plinth panels do not crack, they do not have the effect of peeling and delamination, they do not conduct electricity. Thanks to the ventilated space, condensation is drained from the wall surface.

Vinyl

The profiled material is made from polyvinyl chloride. The matte surface of vinyl siding has a convex texture image, the plane does not require painting after installation.

Properties of vinyl siding panels:

- do not support combustion in case of fire;

- resistant to chemicals in the atmosphere;

- relatively cheap;

- do not absorb moisture, salt.

They produce vinyl panels of different thickness, which differ in characteristics.Modern slats are made from two or three layers. In the composition of the material, more than 80% is polyvinyl chloride.

In addition, they include stabilizers, modifiers, dyes:

- calcium carbonate makes up 15% of the bottom layer and fills the panel structure;

- titanium dioxide stabilizes the top layer (10%), retains color under the influence of rays;

- butadiene in the amount of 1% prolongs service life, increases durability.

Additives are added to the composition to increase the strength against impacts. Lubricants prevent the surface from sticking during release and transport, and concentrated dyes provide color.

Aluminum

Strong strips are lightweight, the square of the cladding, excluding the frame elements, weighs 1.6 - 1.7 kg. Metal lamellas are used to decorate a large country house with siding, while the load on the foundation increases slightly. The aluminum fins are colored with an epoxy powder coating. The spraying is melted in thermal chambers, resulting in a strong layer that is reliably connected to the surface of the panel.

Aluminum siding properties:

- durable, does not burn;

- has color fastness;

- used in humid conditions without loss of quality.

When installed, the strips are easily fixed on a hidden frame, resulting in a surface with the texture of various natural and artificial materials.

The disadvantage of aluminum lamellas is that they have low plasticity, therefore, they use a special technology that takes into account the change in size with changing temperatures. Scratches and abrasions during transportation, unloading and storage are dangerous for the material.

Steel

Previously, such panels were installed on industrial buildings, used to decorate fences, kiosks, and stalls. Modern metal siding is distinguished by a variety of embossing, color, conveys the pattern of wood, the texture of natural materials. You can finish the house with siding under a stone, while from afar such a structure will look powerful, it will be difficult to distinguish it from natural material.

Hot-dip galvanized cold-rolled steel strips are produced. The layer is applied from one or two sides. Perforated edges and a lock are used for assembly during installation, the shape of which balances expansion when heated.

The metal siding is fixed to the supporting frame through oval slots in the lamellas so that there is a possibility of slight displacement to prevent deformation. Steel panels are of significant weight, which must be taken into account when designing and laying the foundation of a house. Impact dents remain on the surface of the strips, which cannot be repaired without removing the lamellas.

Copper

Copper did not decline in popularity even after the discovery of iron. The material is used in design and construction projects, it is successfully used to decorate the walls of a residential building from a bar or sheathe a dacha with siding.

Natural copper is becoming an elite type of facade decoration, emphasizing the individuality of the building. The material has a wide range of applications in terms of different climatic zones. Panels are made for wood from roofing copper 0.55 - 0.65 mm. The surface color is usually dark brown, but differs in many shades depending on the type of raw material.

Copper properties:

- moisture resistance;

- lack of corrosion during temperature changes;

- does not rust, protects the facade from fire;

- long service life.

Installation does not differ from the installation of siding lamellas from a different material. The lamellas are snapped onto the locks, fixed with self-tapping screws to the frame elements. The base is made of metal or wood.

Wood

Cladding panels are made of wood by pressing fibers under pressure.Manufacturers develop their own technologies, use different modifiers to give the original pattern and color. A house covered with wooden siding from the outside imitates a wooden building, houses made of shell rock, aerated concrete, etc. are sheathed with material.

The material has many advantages:

- ecological cleanliness;

- strength, resistance to loads;

- high rates of heat and sound protection;

- resistance to sudden changes in temperature.

The disadvantages are that the wood is highly flammable and does not stop burning. Natural material rots, absorbs moisture, bugs, fungi and microorganisms destroy it. Before use, the parts are impregnated with antiseptics, anti-rot agents. Such processing should be done after about 2 years.

Cement

Fiber cement siding serves as a wall covering for up to 50 years. It is installed on residential buildings, summer cottages, finishing temporary buildings, gazebos, attics. The panels contain wood or cellulose fibers, which are bonded together with cement. It has the advantage over other types of siding in that the fire begins only after half an hour of exposure to high temperatures (+ 500 ° C).

Cement fiber strips do not corrode, there are no moisture spots on the surface. Facade coating is successfully used in the south and north of Russia, since temperature changes do not affect the material. The shape and color of the panels does not change over time, dyes are introduced into the mass during production, so the surface does not fade.

The disadvantage of cement panels is that they have a lot of weight and considerable thickness; a square of the finished area without a frame weighs 7 - 15 kg. The base for the cladding is made strong, reinforced slats of 50 x 50 mm are used or metal reinforced profiles are installed.

Calculation of materials for finishing a wooden house

Step-by-step calculation instructions:

- the area of all walls is divided into plots, then the area of each individual site is calculated, the values are added and the square of the facade is obtained;

- the area of windows and doors is subtracted from the obtained indicator to get the size for the wall cladding;

- calculate the area of the basement of the house if two types of material are used for cladding;

- calculate the squaring of the under-roof overhangs, if panels also need to be installed there.

The resulting value is multiplied by a factor of 1.1 to take into account the overlap of the strips along the length of 15 cm.To calculate the rails, the height of the walls is taken into account, as well as the fact that they need to be installed every 0.6 m, and at the corners they put racks on both sides ...

The corner elements of the siding system are taken along the height of the corners of the house, window slats are taken along the perimeter of the openings, the final and starting strips are taken along the length at the installation site. Brackets for fixing the rails are taken so that there are 4 - 5 pieces for each rail, depending on the height of the facade.

Preparatory work

Before starting work, gutters, hanging lamps, other devices and devices are removed from the outer surface of all walls. If wooden slats are chosen for the frame, they are impregnated with ready-made antiseptics or linseed oil heated to + 60 ° C is used.

They check the integrity of wooden walls, dismantle and replace deformed boards, repair the surface of beams, logs, and strengthen loose elements. Good preparation will help you install the siding so that the finish looks attractive and tidy.

Before installing the frame racks, a heater is mounted on the wall, which is fixed with self-tapping screws with large caps.The slats are fixed with staples over the insulation, then a waterproofing film will be installed on the slats. This will create a ventilation gap between the membrane and the insulation, and the condensate will not wet the insulation layer.

Required tools and materials

To cut the siding, use a jigsaw, grinder, metal scissors or a hacksaw for wood or metal. The tool depends on the cladding material. The panels are fixed to the profiles with self-tapping screws.

For cladding a house with siding, tools are used:

- electric drill, screwdriver;

- laser or water level, square, tape measure from 10 m, plumb line.

Cement slabs are cut with a grinder or circular with a diamond disc. To work with cement-fiber siding, copying machines are used, taps and drills with a victorious nozzle are used.

Materials are prepared for isolation:

- vapor barrier film;

- mineral wool or slab insulation;

- protection from wind and moisture;

- lathing elements.

The brackets are fixed to the wooden wall with self-tapping screws, the steel elements of the frames are fastened to each other with rivets or a self-tapping “flea” screw.

Decorating a wooden house with your own hands

First, they make a crate on the walls. The correctness of the installation is coordinated by level, plumb line and square. A waterproofing film is attached to the profiles, which additionally protects the facade from the wind.

Phased execution of work:

- fixing the guiding elements of the system;

- installation of panels around windows, doors;

- installation of ordinary strips.

First, they put a basement ebb, then move on to the corner elements. They are set exactly in level, on two slats on both sides of the corner. Mount the starter bar so that it is 5 cm higher than the bottom edge of the corner piece.

J-profiles are placed around the openings. The corners of the elements are cut at 45 ° or overlapped. When installing the H-profile, a gap is left up to the base and cornice so that the strips do not deform when heated from the sun.