Finishing the facade of a building is important not only from an aesthetic point of view, but also to protect the walls from the negative effects of atmospheric phenomena. Facing a house with brick panels is an alternative to conventional bricks, characterized by good decorative effect, low weight, and the possibility of self-installation. Another advantage of using the material is the absence of "wet" processes. For the correct installation of the finish, adherence to technology is required, the correct choice of the type of panels and fasteners.

Varieties of brick panels

The cladding presented can be classified depending on the structure: some models are single-layer, others are combined with insulation. They can also be solid (large elements) or composite (the easiest to use).

With a homogeneous structure

This material contains polymer components, modifiers and additives. These elements prevent linear deformation of the product under the influence of temperature extremes and precipitation. Facade panels are resistant to fading and mechanical stress.

Combined structure

Brick house decoration often has a combined structure: it combines polymer and insulation. Polystyrene foam or polyurethane foam is used as insulation. Both layers are bonded to each other without the use of glue by means of hot bonding. The panels have a larger thickness parameter compared to the first group. They provide good thermal and acoustic insulation. The advantage of the material is the simplicity and high speed of installation, but it is expensive.

Advantages and features of the material

The brick facade is resistant to direct sunlight, moisture, changes in ambient temperature. It also has the following advantages:

- environmental and fire safety;

- the ability to withstand serious mechanical stress;

- reducing the time for finishing work (there is no need to use cement mortar);

- long service life;

- the absence of salt streaks on the surface of the cladding (a common problem when using brickwork);

- ease of installation: if the panels are mounted on a crate, work is allowed to be carried out in any weather;

- the ability to choose various textures and shades of the material, its combination in one project;

- light weight of the panels: the load on the foundation is negligible;

- no need for serious care;

- increased resistance to wear;

- small amount of waste;

- versatility (the material can be used for cladding buildings of various shapes);

- reliability of the lock connection.

The lack of brick panels for the exterior of the house is the high cost.

Manufacturer options

Before cladding a house with imitation bricks, you must choose the material for making the panels. Products made of PVC, cement, clay are popular. However, outwardly they do not differ from brickwork.

Clinker tiles

Such facing material is made on the basis of clay, which is fired. Due to the peculiarities of processing, it acquires high strength.The addition of oxides and fluxes to the production raw materials provides a glossy surface shine. The clinker panels contain insulation: mineral wool, penoplex.

The surface does not require complex maintenance: it is enough to rinse it with water from a hose under pressure. Use the finish to decorate new facades or restore old ones. At the same time, it makes no difference what the walls were erected from. The tile is resistant to atmospheric influences and temperature extremes. However, it should not be used for cladding those buildings that are built on a light foundation, since the material is heavy.

Brick siding

Among the plastic options for facing a house under a brick, the most popular is vinyl. It is practical and easy to use. The material is resistant to ignition and combustion, temperature changes. For finishing the facade, thinner plates are used than for cladding the basement.

The advantage of siding is a long service life, which reaches 50 years (with proper care). The mass of the panels is small, so the load on the foundation is negligible. Maintenance involves periodically washing the panels with a jet of water. The disadvantage of the material is the need to use an additional layer of insulation. The elements are fastened to the lathing made of wood or aluminum profiles.

Fiber cement panels

The facade can be clad with composite panels, for the manufacture of which mineral filler, cement, cellulose fibers are used. The components are thoroughly mixed, processed under pressure and dried. The result is a monolithic base on which a decorative layer and protection is applied.

Fiber cement panels are resistant to negative temperatures and can withstand up to 100 freezing cycles. They do not burn, do not succumb to the negative influence of moisture, and have a relatively small mass. Ceramics, acrylics, photoceramics are used as a protective layer.

Required tools and materials

After choosing the material for cladding the house outside, the necessary tool is selected under the brick. For work you will need:

- screwdriver, hammer drill (drill with impact function);

- jigsaw, grinder (for cutting panels);

- hacksaw, scissors for metal (the choice depends on the material used to make the lathing);

- building level (optimal tool length - 80 cm);

- plumb line;

- measuring tape, pencil and cord (for marking);

- hammer, screwdrivers, pliers;

- screws, dowels, screws.

For the manufacture of the battens, you will need wooden slats or an aluminum profile. The following components are also required: starting and decorative strips, outer corner, j-profile.

Facing the house with brick panels with your own hands

Before sheathing the walls with brick panels, you must leave them indoors for several days. The air temperature in the room should be 25 degrees. When carrying out work, you should follow the instructions:

- Preparation of the base. First, check the horizontal and vertical level of the walls. If there are drops of more than 1 cm, the surface is leveled. The base of concrete or brick is primed, and the wood is treated with antiseptic impregnation. An old layer of plaster and nails are removed from the surface.

- Installation of the lathing. In addition to wooden and metal elements, plastic ones can be used. They are suitable for attaching siding. When installing the planks, their level is strictly checked in all planes. The distance between the vertical elements is 30-40 cm. The correct level can be achieved by marking the base with a cord.

- Insulation of the facade. The insulator is placed before or after the installation of the battens. In the first case, first, a vapor barrier, suspensions are attached, a heater is put on them, which is covered with a windproof membrane. Nail the crate.If the frame has already been made, the space between the slats is filled with insulation, on top of which a vapor barrier film is fixed. A ventilation gap is left between the insulator and the panels.

- Fixing the starting bar. It is fixed along the designated horizon. The step between the screws is 30-40 cm. If the bar consists of several sections, a deformation gap of 3-4 mm is left between them. The outer corner can now be secured. It is also used as a cashing for window and doorways.

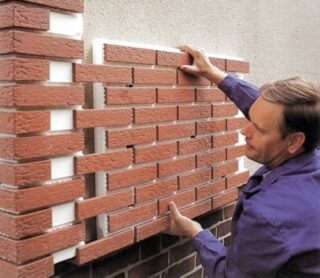

- Fastening panels. Work from left to right and bottom to top. Do not tighten the fasteners all the way. Leave 1-2 mm for the thermal expansion of the panels. The first element is inserted into the starting plate and fixed with galvanized self-tapping screws. Further panels are attached in the same way, snapping the lock connection. A deformation gap of 0.6-1 cm is left to the corner of the base. The elements are staggered, shifting them by ½-1/3 of the length.

If glue is used to fix the material, it is applied pointwise over the entire area of the panel. When joining the outer corner and trim, the latter is trimmed in a vertical position. To do this, it is better to use a hacksaw equipped with a fine-toothed blade. Plastic products are cut with a sharp knife.

Brick panels are the optimal solution for any facade, if you need to carry out the work quickly and as accurately as possible. With proper installation and operation, the finish will not lose its decorative qualities for many years.