Hinged gates with an upper suspension are a sliding structure, which has a number of advantages over a swing gate. Such systems are becoming more and more popular in the private sector. This is justified not only by the functionality of the products, but also by the completely accessible possibility of assembling by hand, which allows you to save a lot on the services of professionals. To make a beautiful and reliable sliding gate with an upper suspension, you need to familiarize yourself with their device, make a competent project and, in accordance with it, carry out the installation.

The principle of operation of a suspended gate

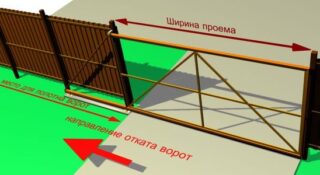

Structurally, suspended sliding gates are a structure designed to close the passage to the courtyard of a summer cottage or a private house by moving a blank canvas along guide profiles. The movement of the mobile part is carried out along the surface of the fence due to muscular effort or an electric drive.

General structure of the structure:

- Canvas. Consists of horizontal and vertical pipes, forming a rectangle and diagonal reinforcement profiles, which serve to stabilize the shape of the gate. On the outside of the frame, sheathing is attached - a picket fence, wood-composite slats, polycarbonate or corrugated board.

- Upper suspension beam (console). It is a steel profile with an opening for placement and movement of roller blocks. Serves as guides for moving the canvas.

- Brackets. L-shaped products connecting the upper beam with the support posts.

- Suspended carriages. Blocks of 4-6 rollers fixed to the frame of the canvas, providing smooth and smooth rolling along the guides.

- Support pillars. Depending on the width of the opening, 2-3 racks are installed, concreted in the ground at a depth of at least 150 cm.

For the convenience of using the entrance group, the gates can be equipped with an electric drive, automatic equipment, and a signal lamp. To protect the guides from debris and water, a ridge is installed above them.

Advantages and disadvantages

Like any engineering structure, suspended sliding gates have pros and cons.

The advantages include:

- Reliability and durability. The system is simple and has few details. This determines its strength and resistance to external factors.

- Save free space. For the installation and operation of the gate, a little space is required along the fence, which is important for houses located on narrow streets.

- Resistant to strong gusts of wind. The sash will never open by itself and will not cause damage to the fence or equipment standing next to it.

- The minimum amount of work to free up space for the gate to move after snowfalls.

Disadvantages of the structure:

- Travel height restriction. The supporting beam is located above the opening in the fence. Because of this, trucks and tall jeeps will not be able to pass under it.

- The need to maintain a clean strip of terrain along the fence under the sash. Grass, bushes, snow - all this stops her.

- Difficulty of maintenance of the guide. Debris, snow gets into the cavity of the upper console, water can freeze in winter, which is typical for cold regions of the country.

In practice, the negative aspects are easily overcome. The main thing is to draw up the correct scheme, carry out the installation according to the instructions and regularly service the sliding system.

Materials and components

The device of cantilever gates is not complicated. For their manufacture, a set of devices is enough, which is in the arsenal of any master. A wide range of materials are presented in hardware and specialized stores.

The following tools are required:

- grinder with cutting and grinding discs;

- electric drill or powerful screwdriver;

- spanners;

- screwdrivers;

- riveter;

- roulette;

- level;

- core;

- clamps;

- magnetic clamps;

- vice;

- paint brush;

- goggles, gloves, respirator.

Materials:

- profile pipe 40x40x2 mm;

- wall corrugated board 200 cm high;

- steel smooth rod 10 mm;

- iron corner 30 mm;

- ladder;

- sheet steel 3 mm;

- rivets;

- self-tapping screws;

- bolts with nuts;

- ball bearings (8 pieces type 300);

- solvent;

- metal brush;

- metal primer;

- acrylic paint;

- rags.

Purchases should be made only from reliable retailers, preferably in trusted retail outlets working with well-known manufacturing firms. It is not recommended to purchase goods on the street or through advertisements - you can run into a fake of low quality.

Step-by-step instructions for the manufacture and installation of suspended gates

Workplace preparation includes the following activities:

- Marking. The perimeter where the structure will be located is being specified.

- Removal of grass, bushes, small objects of house building.

- Leveling the plot. Removing the top layer of soil, laying sand and gravel bedding.

- Placing a concrete post in a ditch or casting a strip of grout.

The manufacture of a reinforced concrete substrate will prevent deformation of the base during heaving of the soil, the growth of grass and bushes, and will facilitate the cleaning of the area from snow and debris.

The procedure for mounting the frame and installing the support pillars:

- A fragment of holes up to 150 cm deep.

- Bottom ramming, backfilling of crushed stone and sand cushion, leveling and compaction of the mixture.

- Anticorrosive treatment of pipes.

- Lowering supports into pits, leveling with stones and props.

- Mixing and pouring concrete.

It is better to use profile pipes with a cross section of 10 cm as supports for the console. Another option is to use reinforced concrete products with embedments, to which brackets can be welded. The mortar must withstand at least 28 days, after which you can use the pillars.

For the manufacture of sashes, corners or shaped pipes are usually used. The advantage of the latter is that by using cuts and curves, an almost monolithic frame with one seam is created. It can be done not in the corner, but in the middle of the span, where it is possible to strengthen the joint.

- Marking and cutting out blanks.

- Laying and fixing parts on a flat surface.

- Welding. First, the vertical and horizontal parts. After checking the correctness of the dimensions, diagonal amplifiers are installed.

- Metal treatment against rust.

- Fastening the cladding board.

The automation for suspended sliding gates is supplied as a set and includes mechanical and electronic parts. First, the drive and toothed rack are installed. Then the control unit is connected and the setting is performed. All you need to do is follow the manufacturer's instructions.

Installing the rail and rollers includes:

- Sawing a 15 mm wide longitudinal hole in the beam.

- Manufacturing of a suspended carriage from sheet steel, pins and bearings by crimping in a vice.

- Brackets are first welded to the supports, and the console is already attached to them.

Installation of roller carriages to the channel:

- Roller carriages are welded to the canvas frame.

- The bearings are inserted into the end hole of the console, after which it is plugged.

- The canvas moves to the stop, catchers and shock absorbers are placed at the junction with the supports.

Finally, the structure is equipped with handles and locks.

Sliding gates are made for years, so you need to immediately choose the optimal size and design for them. It is advisable to draw up several sketches, from which to choose the most successful one.

In order not to face the problem of transport dimensions when entering the courtyard, you can make a removable version of the beam. If necessary, it is enough to remove the blade from the guide, and then pull out the console. The bolts should be covered with decorative caps to protect them from moisture and corrosion.