Slopes are parts of a window opening that frame the window inside and outside the room. They are located at the top and sides of the structure. After the completion of construction, finishing of the slopes in a wooden house is required. The procedure will keep the rooms warm, prevent drafts and dew loss. They are engaged in the design of these parts of the wall if they have not been repaired for a long time and have lost their presentability, cracks appear on them, the paint has burnt out. This procedure is mandatory after replacing the window.

Features of the classification of slopes

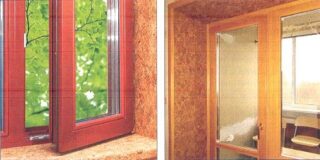

The facing of the slopes is needed to make the interior of the room complete. Window decoration is different in material of manufacture, size and shape. They also classify it by location.

By size

Depending on the dimensions, the slopes are narrow and wide. The second option is suitable for structures that are built from logs. What matters is the actual size of the window block. If it's small, narrow trim doesn't look good on it. Several finishing strips are fixed on a wide area, but the joints between them should not be noticeable.

By location

Slopes in the house are divided into internal and external. The first type is not exposed to the aggressive influence of precipitation. It must ensure the decorativeness of the window opening, eliminate the risk of drafts. In this case, use any finishing materials, even softwood. Antiseptic treatment of the base and facing is mandatory. For work, drywall is suitable, which after installation of the structure is covered with acrylic paint.

Outside slopes must be made of durable material that is resistant to mechanical stress, the influence of wind, precipitation, and sunlight. It is better to use durable plastic or wooden lining, which is covered with a protective varnish. Cement plaster is suitable for finishing. After hardening, it is painted.

By form

Window slopes are not always straight. There are also oblique options. They are installed if it is necessary to ensure an increase in the flow of sunlight into the room. At the same time, the glass is protected from freezing and condensation. Oblique slopes are used for roof windows. Direct finishing is used with standard insulating glass units.

Rules for choosing slopes in a wooden house

The cladding of the slopes protects the frames from the influence of moisture, closes the assembly foam, and increases the operational life of the window. The choice of material for finishing the sidewalls is necessary taking into account the following requirements:

- decorative material;

- resistance to direct sunlight;

- mechanical strength;

- ease of installation and ease of maintenance (it is difficult to attach a solid board to a large slope yourself).

The design should be combined with the material of the window, as well as the general interior.

Plastic

Plastic is a synthetic material that is often used in the decoration of a wooden house. It has a low cost, it goes well with PVC double-glazed windows. This finish is characterized by a sufficient level of durability.

There are 2 cladding options:

- Thin jumper panels.They do not provide reliable thermal insulation, since they have a small thickness. They are cheap, they can imitate natural material, but their strength is low.

- Sandwich panels. The structure contains insulation, which is placed between PVC sheets. Since they are used in a wooden house, it is important to choose a suitable insulator. The panels can be cut depending on the size of the slopes. To decorate the surface of the panels, a colored laminating film is used. You can choose a material with imitation of natural wood.

Plastic slopes are easy to install and easy to care for.

Wooden

Wooden slopes emphasize the beauty of the interior, its naturalness. For work, they use cedar, oak, beech. Pine is an inexpensive option, but it is used to decorate the opening from the inside. The most suitable option is larch. If possible, the same material from which the wall and window frame were erected are taken for cladding.

Wooden slopes have the following advantages:

- environmental Safety;

- reasonable cost (for the most common wood species);

- natural beauty;

- good performance of thermal and sound insulation;

- the ability to choose the texture and color of the material.

If necessary, paint the surface. The disadvantage of the material is the need for processing with protective compounds, antiseptics. Wood goes well with PVC and is more expensive than plastic.

Do not use oak for outdoor decoration, as it can warp under the influence of direct sunlight.

Cork

For cladding window slopes, it is important to choose high quality products. Cork slopes have the following advantages:

- ease of installation, ease of maintenance;

- the material does not accumulate static electricity, therefore it does not attract dust;

- good sound insulation;

- long term of use.

The cork provides unique decorative qualities. However, the material is too soft and expensive. The product is imported, so there is a risk of acquiring a fake.

Plastering

Plaster is often used for finishing slopes. This is an inexpensive cladding option. Mixing the solution requires water, with which the wood does not interact very well. Before applying the plaster, the tree is treated with a primer. If used before natural shrinkage at home, it will crack.

Required tools and materials

Installation of slopes requires preliminary preparation of the tool. To work with wood you will need:

- drill and special drill;

- screwdriver;

- measuring tape and a pencil for marking;

- a hacksaw for wood or a jigsaw with a special blade;

- self-tapping screws, sandpaper;

- sealant;

- polyurethane foam;

- wooden blocks;

- inner and outer corners.

Before fixing the slopes, it is determined how correctly the window block is installed. Any inaccuracies in the installation must be eliminated before finishing.

Do-it-yourself installation of slopes in a wooden house

Before installing the slopes in a wooden house with plastic windows, the surface is prepared. It should be smooth, free of dust, and residues of polyurethane foam. If necessary, the tree is trimmed.

The work on installing slopes involves the following stages:

- Base marking. On the opening, it should be noted where the mounting rail will be located. If the finishing panels are 1.5 cm thick, the distance between the elements of the lathing does not exceed 50 cm. Thus, it is possible to achieve rigid adhesion of the finishing panel to the base and prevent it from warping under the influence of temperature extremes and humidity.

- Finishing preparation. The material must be cut according to the dimensions of the base.

- Fixing the lathing. The slats are screwed on the markings. If the opening is not very even, substrates are placed under the bars.The slats are fixed with self-tapping screws. During the work, it is necessary to constantly monitor the location of the corners: they must be the same along the entire perimeter of the slope. If the panels are fixed vertically, then the slats are screwed horizontally.

- Installation of finishing materials. Installation of panels starts from the frame. However, do not fix the cladding tightly to it: a deformation gap of 5 mm must be left. If the slope is wide, the indent is 1 cm. The ceiling elements are fixed first, and then the side ones. A deformation gap is also left in the corners.

The distance between the frame and the finishing material is blown out with polyurethane foam. It should be borne in mind that it is expanding. All connections are closed with glazing beads or a decorative corner. It is fixed with glue, small carnations. The paint and varnish material is applied to the panels before or after installation. Before this, the surface of the slope is sanded with fine sandpaper.

Plastic panels can be fixed with glue or foam. The slopes are pre-primed to improve adhesion. It is also allowed to use special brackets to fix the elements. Wood trim is often set on polyurethane foam. The installation process involves the following work:

- Preparation of panels. First you need to cut the elements to the appropriate size. The corners must be even.

- Securing decorative elements. Fix them with self-tapping screws. At this stage, the level of the corners is also checked.

- Filling the gap with foam. At the same time, do not forget that its volume is increasing. Excess foam is removed after it has set. It is necessary to blow out the gap so that no through holes remain.

The decoration of the slopes provides a decorative attractiveness of the window opening, protects it from the formation of a draft, the influence of negative factors on the base. It is important to choose the right material for cladding and correctly perform the installation.