The water drainage system from the roof of the building is a complex of elements that are sequentially mounted outside the building on the walls and roof. The drain protects the foundation and the facade of the house from getting wet in the rain, collects precipitation in funnels and directs them to the place where the drains are received. Ebbs for the roof are included in the set of elements, they are made of various materials, the location is indicated in the design drawings of the roof.

Installation of roof drip system

It is possible not to organize the diversion of flows at all, to make an internal drainage network (flat roofs) or to form an external intake system by arranging rainwater drainage from the roof. In the first version, water falls from the eaves around the entire perimeter, falls on the area of the blind area, and the walls of the structure get wet from it. This was done on houses built in previous years. Modern construction methods provide for an organized system.

Internal drainage is done in multi-storey buildings when the roof has a large area and a small slope (up to 12 °). Vertical risers are installed in the middle of the building, they are located in the space of the staircase for possible access during maintenance. Horizontal bends run under the basement ceiling, through which flows are directed to the street behind the blind area of the building.

The roof drainage system consists of the main and connecting parts:

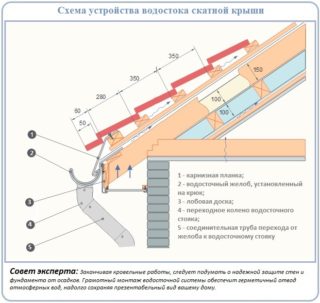

- a gutter in the form of a channel for receiving flowing rainwater and directing it to the place of discharge;

- gutters facilitate the ingress of jets into the collector funnel;

- receiving funnels collect melt and rainwater into the riser pipes;

- vertical collectors in the form of a prefabricated structure on the facade conduct flows downward;

- gutter plugs, installed at the ends of the drainage channel;

- tees are used for routing a system of pipes, risers;

- contours in the form of knees are made when the collectors bypass architectural protrusions on the facade;

- the grate-catcher is placed in the mouth of the funnel-receiver to protect it from foliage and debris.

The gutters are attached to the roof structure using metal brackets. There are short and long options for brackets so that it is convenient to support the gutter, create the required direction and slope of the drain. Sheer risers to the walls of the building are fixed with clamps, ensuring a correct and stable position. The fastener is a ring along the diameter of the collector with a pin driven into the vertical fence of the house.

Calculation and design rules

To calculate accurately, you need to subtract the lengths of connections, angles, tees from the total length. But more often they do not do this, leave the resulting length value, taking into account small waste when cutting to size. Count the number of turns, contours, knees and other elements.

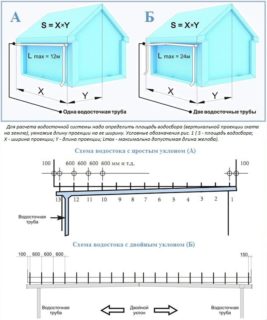

The number of funnels is taken depending on the cross-section of the drain channel, so that the water has time to go into the vertical risers, and not overflow during a heavy downpour.As a standard, they are placed every 8 - 10 meters around the perimeter, the initial acceptance points are provided at the corners of the house.

The rules for calculating the diameter and section:

- the square of the roof covering is less than 50 m² - the optimal installation of a gutter with a width of 100 mm and a collector with a diameter of 75 mm;

- area up to 100 m² - gutter 125 mm, riser section 90 mm;

- the value exceeds 100 m² - a channel of 190 mm is accepted, pipes with a diameter of 120 mm.

One receiving funnel with a cross section of 150 x 150 conducts water from 150 m² of surface or from 15 m / s along the perimeter of the roof. Plumb pipes are counted according to the number of funnels. The number of fixing holders is taken so that the step between them is 0.5 - 0.6 m. In the places where the receiving funnels, connectors, tees, bends are installed, a pair of elements is placed. Wall fasteners for roof drain pipes are counted every 0.8 m.

Varieties of ebb

The roof gutter includes main parts and auxiliary elements. All parts and assemblies must be strong, resistant to loads and not deformed from sudden snow falls or wind. The surface is coated with anti-corrosion properties against harmful substances in the atmosphere, with the help of color they give an attractive appearance.

The cross-sectional shape of the gutters is:

- round;

- rectangular.

The first type is preferable, since the absence of corners reduces the resistance of the jets when moving, but square ones have a large throughput volume.

According to the material, ebb tides on the roof are distinguished:

- galvanized;

- copper;

- metal;

- plastic;

- aluminum.

Roof drains are chosen according to the quality characteristics of the material, which differ for each type. Some features are more pronounced, there are advantages and disadvantages.

They put more galvanized, plastic outflows because of the acceptable cost. Non-ferrous metal products are distinguished by long-term operation, but they have a high price.

Galvanized

Galvanized roof outflow is characterized by:

- low cost;

- strength, which depends on the thickness of the metal;

- resistance to temperature extremes;

- ease of cutting and installation in the mounting position.

Uncoated galvanized metal lasts longer than iron, but degrades over time from the atmospheric acids found in rainwater. Such gutters are not compatible with all types of roofing. If the material contains bituminous components, they can melt in the heat, get on the galvanized metal. When reacting with bitumen, the zinc layer is destroyed and rust is formed.

Galvanized products for draining are made of galvanized iron up to 1 mm thick with a top coating of polymer components (plastisol, polyester, pural). The finishing layer increases protection against negative factors, reduces the sound of metal when dripping and moving birds.

Copper

When installing a copper roof drain system, the following qualities are taken into account:

- corner, connecting parts, tees are made from a whole sheet without the use of welded seams;

- the length of the collectors and gutters can be selected in the range of 0.1 - 9 m;

- all elements have built-in gaskets.

Surface corrosion and oxidation stops after a few years and a patina appears, giving the copper a noble appearance. Manufacturers offer ebbs with an artificially aged surface with a green tint and an oxidized layer like brown copper.There are options with a tinned tin layer (silver color).

For installation, they invite experienced specialists who are familiar with the specifics of working with copper elements. During assembly, do not break the top layer of connections and other parts. If necessary, soldering is used instead of welding.

Metallic

Metal plums are popular for their qualities:

- high strength when loaded with snow, water, icing;

- resistance to temperature changes without surface destruction;

- long service life due to polymer protection;

- low cost;

- a large selection of shapes and colors of ebbs, pipes.

Such ebb tides are placed on slopes made of profiled sheet, metal tiles, slate tiles and other piece materials. In metal weir systems, there are no parts to compensate for the temperature increase, since the material has a low coefficient of expansion.

Plastic

Plastic products have established themselves as resistant systems to adverse factors, their surface is not subject to corrosion. PVC ebb tides withstand heat and do not bend under the influence of the sun. Drains are collected using rubber gaskets; installation does not require the use of powerful brackets, since the material is lightweight.

The inner surface is characterized by increased sliding, so plaque and dirt do not accumulate on the surface. Plastic dampens noise from falling rain drops, its use does not harm the surrounding space and humans. The cost of the plastic system is available to the average buyer.

Aluminum

The main advantages of structural metal:

- lightness and plasticity;

- resistance to negative atmospheric factors;

- ecological cleanliness.

The disadvantages include low strength, so a larger number of holders and clamps must be installed in the system. For hardening, aluminum is alloyed with copper and magnesium components, and duralumin is obtained.

The metal is painted with epoxy powder paint in ovens, so you can choose from different colors of aluminum shims.

Do-it-yourself correct installation

The brackets are fixed to the rafters, lathing or frontal boards. The first and second options provide for the installation of hooks during the installation of the roof. First, they put the extreme holders, then the rest, taking into account the slope of the gutter, fasten each bracket with two self-tapping screws. Pull the cord to maintain a straight line.

The system can be completely assembled on the ground, then installed on existing hooks if the overhang is short and there are several helpers. For large roofs, each element is connected in a suspended state at the place of organization of the drainage system.

The plastic elements of the drain are glued with a special compound, and plugs are also placed on the ends. In metal, one edge is bent, the element is joined, then the fold is returned to its original position. For vertical pipes, clamps are first attached, then a collector is placed and tightened around the perimeter.

To bend the plastic, it is heated in the right place, and the metal drainage is bent with pliers. The cuts are made with a hacksaw for metal, the burrs on the plastic are cut with a knife, and a file is used on the metal. The place of the cut on the galvanized sheet is treated with a protective compound.