A multifunctional hearth in a brick house is a complex structure. Previously, professional stove-makers were involved in construction. In the information age, there is enough information on the network about how a do-it-yourself brick heating and cooking stove is being built, the order of which with explanations can be taken from the Internet. Before work, you need to familiarize yourself with the construction technology, learn the intricacies of arranging a wood-burning hearth.

What is the order of the furnace for?

The order for different models is designed so that after the end of the masonry, the brick stove can work effectively. The smoke in the stove does not pass vertically or horizontally, but makes numerous turns. This is necessary for the heated air to contact the brick surface for more time and heat the wall.

In each row, the bricks are placed in a specific order to obtain such smoke paths. Hot gases may not find a way out, start moving back into the room, if you make a mistake when performing the order.

With the help of the scheme, it is easier to work, you do not need to think over the order of the masonry yourself, calculate the distances, intervals. In the general drawing, there are only the dimensions of the furnace, but there is no location of individual stones, the dressing of the seams is not shown.

Facets and parts of bricks

The end of the brick is called a poke, the wide flat side is called a bed, and the side surface is called a spoon. The ribs of the product are called trunks. The masonry is carried out by placing the product on the bed, which is considered a work surface. In the only version, the elements are placed on spoons, if the wall is erected in а bricks.

Parts of stones, other than full bricks, are intended for making corners, turns of walls, have conventional names:

- three-four (nine);

- four (quarter);

- half.

The brick is divided into parts with a pickaxe, hitting the spoon, and not on the bed, while the stone is held, resting on an edge. A small volume of incomplete prefabricated elements is ordered from the supplier.

Varieties of brick ovens

When choosing a stove model for a brick house with a stove, the need for cooking and heating is taken into account. At the dacha, only cooking tiles are more needed if the owner does not live there all year round. In the house, the area that can be allocated for the stove is determined, the size of the structure depends on it.

They take into account the possibility of installing a chimney, the way it is taken to the street, the option of passing through the ceiling. If the house is only in the project, the foundation for the furnace is provided in advance.

Common types of brick hearths for the home:

- construction according to Swedish technology;

- small oven for cooking;

- Kuznetsov's stove.

A small-sized design is suitable for a small kitchen. The height of the fireplace or stove with tiles depends on the room and model.

To extract smoke, use steel, brick pipes, put sandwiches, coaxial collectors.

Swedish oven

The variant is distinguished by its efficient fuel consumption and fast heating. It is used in small houses of year-round residence, or is placed for additional heating of distant rooms. The peculiarity of the structure allows you to heat the floor surface next to the structure.A boiler can be inserted into the Swedish one to organize the DHW circuit.

The building has a canal system, but it is also equipped with niches that work like hoods. First, the lower niche is heated, then the spacious upper cavity. The first, second and last heat is used to raise the temperature. Hot smoke flows down from the firebox, and instead of a chimney, a crossflow is built under the oven. If the wood is burnt out, you need to move the valve to the closed position.

Small cooking stove

A niche is built into a small-sized heating stove where the hob is located. An oven or container for heating water is placed in the second niche. A brick stove is used for drying food and clothes.

The structure includes departments:

- furnaces;

- two functional niches;

- smoke channels;

- blower;

- openings for maintenance of flue channels and pipes.

Doors for the firebox, latches, corners for framing are used factory-made, and the oven and heating water tank are welded from a metal sheet. The baby oven measuring 0.64 x 0.51 or 0.89 x 0.51 m can be placed in the corner or in the center of the kitchen. For heating adjacent rooms, such a structure is placed in a wall opening. The hearth is placed on a solid concrete or columnar foundation.

Kuznetsov ovens

Such furnaces are called bell-type furnaces due to the presence of voids in the structure for collecting hot smoke. There is a stove with a brick oven, a cooking stove and a stove bench are built in there. Variants with one cavity have been developed or two-bell furnaces are being built. Limited cavities have a specific shape and play the role of heat separators.

Hot air enters the bell, lingers for some time, transfers energy to the walls of the furnace. The principle of free redistribution of gases is used, while the cooled streams are lowered and fed through a short channel to the second bell. There, the smoke gives off the rest of the heat and is discharged outside through the pipeline system.

Pros and cons of brick ovens

When heated, the surface emits steam; when cooled, it absorbs it. The porous material helps to regulate the humidity in the room, in contrast to the gas equipment, which dries the air.

Advantages of brick hearths:

- the heat capacity of the material, therefore, fuel is less often placed in such furnaces;

- autonomy, energy independence, ease of maintenance;

- available type of fuel (coal, peat, firewood, briquettes).

The downside is that large rooms take a long time to warm up, so advance kindling is required. The massive structure requires a strong recessed base for support. Masonry errors lead to malfunction, which can only be corrected by disassembling and completely reworking the furnace.

How to choose a brick for a stove

Varieties of refractory bricks:

- refractory;

- fireclay (alumina);

- quartz;

- carbonaceous.

You cannot take sand-lime brick or any kind of hollow form, only solid stones are used. The material must withstand the temperature of +900 - 1000 ° C without destruction, not have chips and defects on the surface. A type that is resistant to the action of chemistry is chosen, especially for slag deposits. Tapping the element should produce a metallic-tinged sound.

Selection of sand and mortar

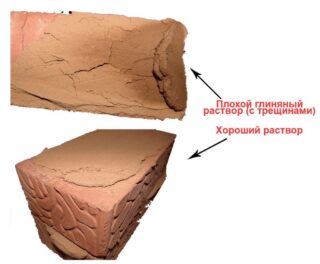

In the store you can buy ready-made dry mixes for laying ovens, which are brought to readiness by adding water and stirring.Heat-resistant and refractory types are used, which allow them to withstand an increase in temperature up to + 1000 ° C without irreversible deformations.

The solution must not react with chemicals. Do not use ordinary cement-sand mixtures, which are destroyed in difficult conditions, do not have plasticity.

Place to install the oven

Heating equipment is located at the inner walls of the room, where there are built-in smoke exhaust ducts. More often, the stove is put in an open way, when all the walls give off heat energy to the kitchen. It is so convenient to carry out inspections, maintenance and cleaning of canals. They try to place them near the entrance to reduce the distance for carrying fuel.

It is undesirable to install it against an outer wall with windows, with this arrangement the room is darkened, and the stove occupies the most illuminated area. If the structure is adjacent to one wall, that side is not used to supply heat. A gap is made between the partition and the stove to increase the heating efficiency.

Preparing the necessary tools

Other tools:

- trowel, pickaxe;

- tape measure, pencil;

- drill with a whisk;

- grinder with a stone cut-off wheel.

For even masonry, a device is used, which has the name ordering. This is a wooden or steel lath on which marks or notches mark the location of each brick.

A cord is used, which is pulled after installing the corner elements, it outlines the top of the stones of each row.

Popular bugs

Inexperienced craftsmen put dry bricks into the masonry, but it is better to soak the material. It holds better, adheres more firmly to the solution. This results in more accurate and even masonry seams. Use a wide bucket of water, where the elements are placed for 2 - 5 minutes before installation.

Narrowing the smoke channel in relation to the standard size reduces draft, and damp firewood will not burn. When installing the firebox door, often no gap of 0.5 cm is left around the perimeter to compensate for expansion. After installation, the gap is filled with asbestos cord or sand mortar.

Iron partitions are placed inside the furnace, but it is better to use a brick placed on the edge. This is due to the different expansion of the ceramic and metal.

The cavity of the oven should not be placed close to the firebox; it is better to place it above the heating chamber through the decks. This will heat up the bottom evenly, and the baked goods will be baked equally from all sides.