The steam room is the main room in the bath, but certain requirements are imposed on its arrangement. A project before construction is created for the competent planning of rooms and functional areas. The owners do the work on their own so that the room emphasizes its individuality, meets the standards, fire and sanitary requirements. The steam room in the bath, aesthetically decorated with your own hands, creates an atmosphere for psychological relief and purification of the body.

- General information about the steam room

- Steam room design

- Requirements for the premises

- Optimal dimensions

- The location of the stove, windows, doors

- Preparation of tools, materials

- Warming the room

- Installation of electrical wiring

- Furnace installation

- Construction of regiments

- Door assembly

- Finishing the premises

General information about the steam room

The steam room is heated hot, hygienic water procedures are carried out in it. Visitors wash with body warming in hot air, while the amount of warm water used is limited.

Paired are divided into types:

- sweat;

- cervical;

- steam.

A sweat room is where people sweat to cleanse themselves. After warming up and the appearance of sweat, the visitor rubs the skin, whips the body with a broom, and rubs it with hairpads. This type also includes standard Finnish saunas.

Shaech (washing) baths are distinguished by the technology of washing in a hot room. The liquid is poured into small vessels, for example, troughs, basins, bowls, barrels. To wash the body, use soap, alkaline agents. After dousing it becomes cold, so the air in the room is heated to high temperatures.

Steam baths are distinguished by the fact that washing occurs when condensation appears on the skin, due to high humidity and steam. Evaporation in the form of bath mist and smoky clouds is obtained by pouring water over hot stones.

Steam room design

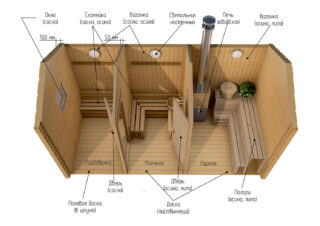

As a result of the design, the functionality of the steam room in the bath is optimized. Correct development at this stage contributes to the organization of effective recreation, saves money on construction, arrangement and decoration. The project of a private steam room in the country takes into account the number of visitors, the dimensions of the building depend on this. Sometimes a bathhouse is attached to the house, but this arrangement has its drawbacks.

The project and documentation for the construction includes sections:

- plan of the foundation, walls, roof;

- layout of internal rooms, their convenient location;

- water supply and sewerage construction system;

- electrical wiring, connection diagram to the main source;

- ventilation system plan;

- the procedure for installing heating equipment, a water heating boiler.

Steam rooms can have one room with a dressing room, but modern projects involve bath complexes with a designated resting place, massage department, hairdresser, and nail salon. They provide terraces with access to nature or to the pool, make a room combined with a barbecue or barbecue for barbecue.

Requirements for the premises

In the steam room of the bath, effective ventilation or a scheme with air recovery and purification is required. The system is regularly cleaned, once a year, disinfected.

GOST 32.670 - 2014 contains general requirements for couples:

- if the sewage system is not connected to a common collector, provide a local drainage and collection scheme;

- the water supply system must regularly supply water of appropriate quality;

- lighting must be installed in the steam room, the number of points is calculated according to the norm

- before visiting the steam room, a person should be able to leave things in the dressing room or dressing room;

- hair drying units, scales, foot baths, wash basins are placed in a room that is located separately from the steam room;

- quick removal of water is organized from the floor so that it is not slippery.

The steam room uses materials that can withstand strong heat and high humidity, while not emitting components harmful to health into the atmosphere. Indoors, single-tier benches, two-tier shelving made of timber, hewn logs with wooden shelves are placed to make it convenient to rest.

Optimal dimensions

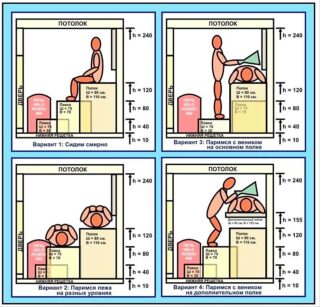

The device of a bath with a steam room assumes compliance with height standards. The parameter does not go beyond 2.1 - 2.4 meters to ensure high-quality heating of the internal space. The width is planned depending on the number of shelves and their location. There may be a stove in the steam room, or it is taken out to the dressing room. If the heater is located in the steam room, this should be taken into account when drawing up the room plan.

To save space in the steam room, multi-tiered shelves are installed to accommodate more people. The stepped shelves are made of such a height that the person sitting on the upper bench can rest his feet on the lower one, and also the person climbed the steps to the upper tier. A separate bench is made for the bathhouse attendant, the height of which is planned to be 70 - 90 cm.

The first level of the shelves is placed 40-50 cm from the floor. The benches for sitting are made 60 cm wide, and a comfortable lying is provided by a width of 91 cm. The length of the shelves is provided from 1.5 meters and more so that you can stretch your legs. In the sauna, the seats are 50 cm wide.

The location of the stove, windows, doors

The stove is placed in the dressing room to provide continuous heating if the steam room is in operation. Garbage with fuel is not brought into the room; it is possible to organize drying of firewood next to the hearth. There is clean air in the sauna, since there is no carbon monoxide, and space in the steam room is saved. The stove draws in air from the dressing room, so supply ventilation is installed there.

The windows in the steam room are not always made, but the opening can increase comfort if it has a panoramic view function. Special designs of double-glazed windows with tempered glass are used, and a rubber or wood pad is placed on the handle so as not to burn yourself on the hot metal.

The door to the steam room is provided from the dressing room, sometimes they make an entrance to the washing department. For the steam room, according to the safety instructions, it is mandatory to open the door outward, away from you. The flap in the box is placed tightly, without gaps, while there should be easy opening. On the porches, insulating gaskets are used so that warm air does not leave the steam room.

Preparation of tools, materials

For the floor, bars are prepared on logs with a section of 50 x 50 mm, boards are chosen with a thickness of 30 mm or more. If a pouring floor is arranged, the elements should not contain grooves and spikes on the sides.

Racks of shelving with benches are made with a section of 100 x 100 mm, bearing girders are arranged from material 80 - 90 mm. For sitting, take boards from 30 mm thick, the step of the crossbars depends on this.

Use the tool:

- tape measure, level, plumb line, carpentry square, marking pencil;

- drill, screwdriver;

- hacksaw for wood, grinding machine, emery machine, chisel, plane;

- hammer with metal and wooden head, pliers.

Use wood with low thermal conductivity so as not to burn yourself. It is preferable to use larch, aspen, birch, fir with high density and moisture resistance. Coniferous pine and spruce are not used for interior decoration and bathroom furniture, since resins are released, which the breed contains in large quantities.

Warming the room

It is better to insulate a steam room inside than to put an insulator outside. The peculiarities of the room are such that steam and high temperature must be kept in the room, and with external cladding, part of the energy will be spent on heating the wall. Condensation that appears on vertical fences will lead to their deterioration and gradual destruction from rot.

Insulation is used:

- mineral wool, stone wool, slag wool;

- foil-clad polystyrene, penoizol;

- extruded polystyrene foam.

Mineral wool is quickly saturated with moisture from condensate and steam, therefore, for its operation, a counter-grill is required to create ventilation. This design reduces an already small space. Foil-clad material that is not moistened and has a small thickness acts more efficiently.

A layer of foil reflects infrared rays into the steam room, but this is important if there is a stove in the room. The insulation is combined with the waterproofing of the steam room. Roofing material, special vapor-permeable membranes, or thick polyethylene are used as an insulator.

Installation of electrical wiring

Before you make a steam room with your own hands, you need to remember that due to the humidity and high heating of the air, certain fire safety requirements are put forward to the wiring. In the steam room, the wire insulation must withstand up to + 170 ° C.

Use cable brands:

- flexible stranded copper wire of the category PRKA, PVKV, RKGM, PRKS;

- stranded and single flexible wire PMTK (works up to + 200 ° С);

- imported wire OLFLEX HEAT 205 (can withstand up to + 200 ° С).

In steam rooms and saunas, wiring in iron pipes and sheaths is not permitted; hidden wiring in safety hoses and ducts is recommended. With open wiring, asbestos is placed under the cable so that 10 cm of the lining material looks out from both sides.

Do not install plug-type sockets, switches, junction boxes in wet steam rooms. The luminaires are mounted in protective housings against moisture, protection class IP24, they cannot be placed on the ceiling, but only on the wall.

Furnace installation

Most often, the stove is connected to the steam room by the channel of the firebox, while the doors of the hearth are taken out into the dressing room.

How to put the stove in the steam room with your own hands:

- make a foundation or a separate reinforced concrete base;

- a channel is formed in the wall adjacent to the steam room;

- the stove is mounted so that the ceiling is at least 1.2 m before the ceiling;

- the smoke exhaust pipe is placed vertically so that it does not touch the wooden parts of the ceiling.

The place for the stove is chosen so that it is convenient to dismantle part of the wall under the channel in the steam room without prejudice to the placement of stepped shelves. The foundation is trimmed from above with a heat-resistant material, a sheet of metal is placed on top.

Use asbestos-cement panels, foam glass. A sheet of iron is stuffed in front of the door of the stove vent so that it protrudes 10 cm from both sides of the stove. The channel in the wall leading to the steam room is finished with red brick.

Construction of regiments

The device of a Russian bath assumes a comfortable sitting or lying during the procedure. Single-tier shelves put a bulge between the walls, if convenient, make a structure in the corner. The benches on the ground floor are mobile so that they can be dried outside. If the stove is located in a steam room, make at least 80 cm from the nearest shelf to it.

Instructions for assembling a single-tier bench:

- cut lumber into racks, crossbars, struts;

- seating boards are sanded, laid out top down;

- at a distance of 200 mm from the ends, transverse bars are attached;

- spacing is fixed to the racks at a height of 150 mm;

- legs are attached to the crossbars, rubber pads are nailed to the ends;

- make a back.

Wooden pins are used for connection. The use of steel hardware is allowed, but they are driven inside so that the hats do not protrude on the surface of the tree, otherwise the visitor will burn when touched.For shelves in several tiers, racks are attached to the wall, girders are placed on them and boards for sitting are mounted. The structure must be stable and securely fixed to the vertical plane.

Door assembly

They use doors made of wood, choose dense and durable species in which hinges and handles will hold well.

Stages of door installation:

- assembly of the box, canvas;

- marking and inserting parts of the hinges separately on the sash and sash;

- installation of the box in the opening with spacers before foaming;

- hanging the canvas on the hinges;

- trimming foam;

- installation of a vestibule, seals;

- fastening platbands on both sides of the door.

In wooden buildings, when installing the fillings of the openings, a casing is made, which does not allow the door to warp along with the shrinkage of the bath. This design works apart from the walls, so it is not rigidly attached to the ends. The casing of the T-shaped or C-shaped type is made on the lateral surface, respectively, elements are cut out at the ends of the walls to match.

Finishing the premises

In the finishing of the floor, walls, in the construction of benches, polished lumber is used, therefore, after installation, it is enough to walk with sandpaper. This is how the raised villi that appeared in the process of working with wood are removed. For finishing, compositions are used to give attractiveness, emphasize design elements.

They purchase natural-based products for processing wooden floors, walls, benches. Coloring is carried out when the steam room is not working, so that the products dry in natural conditions. Synthetic dyes and varnishes are not used for the steam room, since they emit harmful substances.

Surfaces are treated with linseed oil, special antiseptics and wax. Sometimes oil and wax are combined for better impregnation. Wait at least 12 hours between applying several layers for the product to be absorbed and dry.