If it is not possible to connect to central heating or bring a gas line to the house, you have to organize an autonomous heating system using solid fuel. An excellent solution to this problem is a brick wood-fired home stove with water heating. Thanks to the design of this type, it is possible to maintain heat in all rooms, regardless of the location of the fireplace.

Brick stove with water heating in the house

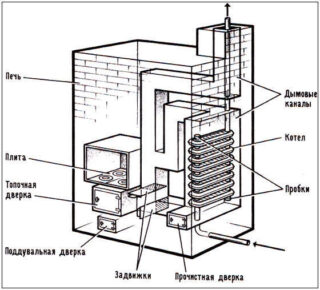

The construction of stone kilns has a long history. The products were used to heat private and public buildings. Firewood was used as fuel, which was easy to get in any area. During the construction, fireclay and refractory red bricks, special masonry mastics, cast iron doors, grate bars, chimney valves are used.

The brick oven with a water boiler is a modification of the standard type device. The structure itself remains the same, but a container and pipes are added to it, through which the coolant flows. Usually this is water, but antifreeze is poured in buildings that are visited periodically. Thanks to this, not one is heated, but all the rooms into which the circuit is brought out.

Features of brick ovens

A stove for a brick house with water heating is expensive; only an experienced stove master can cope with its construction. In addition to work, you will have to pay for special materials - fireclay stone, clay, cast iron and stainless steel fittings. In addition, an effective and safe chimney with a height of at least 400 cm will be required. A characteristic property of the structure is long heating followed by prolonged cooling, which can last several hours.

What is a heating circuit for?

A classic Russian stove is usually installed in the far corner of one of the rooms of a house or dacha. Usually this is a kitchen-dining room, where people are occasionally. When the fuel burns, heat is released, which is transmitted through the walls and the chimney into the room in the form of warm air.

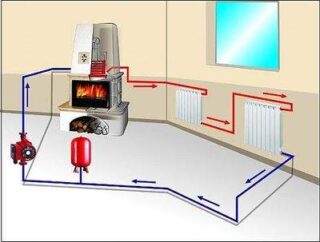

The heating circuit is designed to transport the heated coolant through the rooms, where it is necessary to maintain heat in the cold season. The device consists of a metal heat exchanger, underwater and outlet pipes, piping and radiators. In fact, this is an analogue of autonomous gas boilers installed in buildings connected to central communications.

Principle of operation

The heating element, depending on the design, is located in the firebox or in the area of the chimney pipe. In both cases, it is affected by the high temperature generated by the burning fuel.

The water heated in the element expands and becomes less dense. The cold liquid in the system is heavier and squeezes the heated media out of the oven. It enters the pipes, passes through the system and returns to the heat exchanger in a cooled state. In houses with a large area or for heating the second floor, a circular pump is installed. Thanks to this, the liquid moves continuously, which prevents its stagnation, boiling and metal burning.

Advantages and disadvantages

The stone stove has the following advantages:

- High efficiency.Depending on the design, it is 0.7-0.85. This indicator is achieved due to the well-thought-out design of the structure.

- High heat resistance. Stones, unlike metal, do not burn out for decades. There is no deformation from exposure to high temperature and contact with water.

- Appearance. The patriarchal atmosphere created by the hearth contributes to the creation of comfort and coziness.

- Versatility. A heating and cooking stove with a heat exchanger can be used for cooking, drying things, heating the entire building.

- Possibility of placing large heat exchangers, both in the firebox and in the chimney ducts for heating water from heated gases.

Disadvantages:

- Great weight. As a rule, you need to make a separate foundation.

- Solid dimensions. The object takes up quite a lot of space.

- Considerable investments in construction. The laying of the hearth takes a long time.

If you make a water circuit for the stove with your own hands, this will bring significant savings on heating.

System characteristics

A heating system based on a brick wood stove is designed in advance. The following characteristics need to be determined:

- the size;

- the number of turns in the exchanger (two-, three-turn);

- produced capacity;

- length and outline of the contour;

- the capacity of the pipeline and radiators;

- temperature Range;

- fuel used;

- additional options (oven stove).

When planning the installation of heating in a wood-burning hearth, you need to correlate the dimensions of both devices and their compatibility.

Stages of work

The installation of water heating in a Russian stove begins with measurements, calculations and drawing up a drawing. At this stage, you need to think carefully about everything, without missing any details.

After that, the work is carried out in the following sequence:

- Making your own foundation for the hearth.

- Laying out the order.

- Heat exchanger installation.

- Connecting pipes.

- Manufacturing of piping and radiators.

- Expansion tank connection.

If there is a possibility that the room will be idle in the cold season without owners, a backup electric boiler should be installed, which will prevent the water from freezing in the absence of combustion in the firebox.

Heat exchanger for oven

A do-it-yourself water jacket for the oven is made for specific requirements and conditions. A place is allocated for the heat exchanger at the construction stage or already in the finished device.

The heat exchanger has the following features:

- the number of turns - 2-4;

- wall thickness - 4-5 mm;

- pipe diameter - 5 cm or more;

- material - stainless steel, copper, cast iron.

During installation, gaps are left between the register and the walls so that there is room to compensate for thermal expansions and efficient heat transfer. There must be access for maintenance, replacement and cleaning of the coil.

To ensure a constant flow of fluid, a pump is installed on the return line. But even if it is present, a slight slope must remain so that an air lock does not form.

For installation, you will need the following tools:

- a hammer;

- chisel;

- Master OK;

- roulette;

- level;

- soldering iron;

- adjustable wrench.

To avoid injury, you need to use a protective mask and gloves.

Heating and cooking oven with a water circuit

For installation, you need to prepare consumables:

- stones and bricks;

- ingredients for the solution;

- plastic pipes;

- clamps;

- radiators;

- coil.

In accordance with building codes, a square meter of the hearth provides heating for 35 squares of the room. Based on this, the dimensions of the furnace are calculated, and the register is already selected for it. Extremes must be avoided here: a small hearth will not be able to develop sufficient productivity to generate the required amount of heat.A furnace that is too large will take up a lot of space, and its operation will be associated with excessive consumption of fuel.

The process of installing the water circuit itself is carried out in the following sequence:

- Carrying out markings in accordance with the developed project documentation.

- Partial dismantling of the structure. This must be done carefully in order to reuse the removed fragments.

- Cleaning the firebox, installing support brackets. Coil installation and alignment.

- Connection to the register of pipes made of heat-resistant metal. Couplings, adapters or welding are used.

- Closing the firebox with removed or new stones.

- Installation of an expansion tank, piping and radiators. Pressure testing of the assembled system.

The control firebox is carried out with a filled system after the solution has completely solidified. The first time newspapers and brushwood are burned, then wood chips and only after that firewood.