Frame construction has become a common technique in the construction of multi-storey or hangar buildings, private houses. The technique attracts with its simplicity and speed of construction. However, the walls and the cake of the floor of a frame house have special features.

The device of the pie of the floor of a frame house

Frame technology most often refers to the Canadian technique. It differs from other options in that here the floor, and not the foundation, acts as the basis for the frame and walls. During construction, floors are first laid on the foundation, and then vertical posts are installed on them.

This feature determines an unusual floor structure, which is being erected in stages:

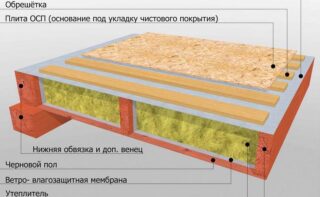

- Most often, floors are arranged on logs - wooden beams or planks mounted on a foundation. Lags are the first layer of such a pie.

- A rough floor made of unplaned boards, slabs, less often plywood is fixed on logs or sheathed them from below. Each option has its own pros and cons, so this point is discussed in the project.

- The structure is waterproofed with moisture and windproof membranes. It is not recommended to save money and use polyethylene film, since the latter does not allow steam to pass through, which increases the risk of condensation occurring directly in the thermal insulation layer.

- If the lags are sewn up from below, cavities remain between the beams, into which the insulation is laid. If the flooring is placed on top, a crate is placed on the waterproofing, and foam plastic plates, mineral wool mats are placed in the resulting cells, expanded clay is poured.

- The insulation is protected with a vapor barrier film - it does not allow steam to pass through and prevents the formation of condensation.

- The next layer is a substrate for the finishing floor. It is chosen taking into account the characteristics of the finishing flooring.

- The cake is completed with laminate, planed boards, parquet, linoleum or other flooring.

General scheme. Depending on other features - the type of foundation, insulation material - the design can be changed.

Features of the frame structure

Frame technology determines a number of factors that must be considered:

- The structure is very light. A light foundation is being built for him. In areas with a low groundwater level, a columnar base is sufficient, for more complex ones, with heaving soils, a pile base. Rarely use tape shallow. The type of foundation affects the construction of the subfloor. In a building on a strip base, you can lay the floor on the ground.

- For insulation, you can use any materials, however, preference is given to non-combustible, since a wooden frame and plywood-based sheathing already make the house fire hazardous.

- For the frame and for the logs in the frame house, only well-dried wood is taken. Thus, shrinkage and drying out of the tree is prevented.

- The subfloor is laid before the construction of the wall frame. This is a feature of Canadian technology.

- When arranging the subfloor of the second floor or attic, the pie includes sound insulation, for example, a layer of acoustic wool. The frame structure conducts sound well, to get rid of excess noise, additional measures are needed.

Before using boards and beams, the material should be treated with antiseptic impregnations.

Methods for arranging the floor of a frame house

Depending on the type of foundation, it is possible to arrange 2 types of floors: on logs and on the ground. The first option provides a ventilated subfloor. It protects the house from freezing and condensation. Rodents have nowhere to start here.

Ground floors offer greater strength and reliability, especially if it is decided to build a concrete screed. However, floating floors cannot be made here: they are the base for the frame, not the foundation.

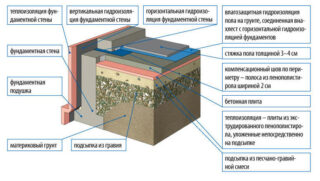

Monolithic floor

For this option, a trench 30-50 cm deep is dug within the foundation, covered with sand and crushed stone, and this mixture is tamped at the bottom. In most cases, this area is already the first layer of the subfloor. In case of high groundwater, it is recommended to lay waterproofing on the layer of sand and crushed stone and arrange a second layer of fine stone and river sand. Instead, you can make a concrete rough screed.

After waterproofing the base, a heater is laid. The easiest way is to fill the site with expanded clay and pour concrete. You can also take plates of expanded polystyrene or foam.

A "warm floor" heating system is installed on a concrete screed.

Frame floor

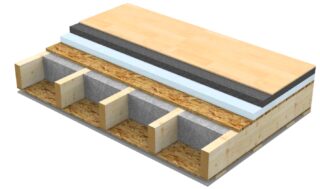

Flooring on joists or beams involves laying wooden beams or planks on a foundation. The use of boards is more rational. They are fastened to the lower harness or to the bed, which is also advised to be made of boards, and not timber. Then the lags are installed. If necessary, it is allowed to build up overlapping logs.

The remaining layers of the cake depend on the material used.

In rainy regions, strapping is often installed. The logs are fastened, and they begin to arrange the subfloor only after installing the roof. It is assumed that this way the flooring materials will not be affected by rain and snow. In fact, it is better to build a rough base and cover it with a film or roofing material.

Choice of materials

- Since the insulation is quite light, boards up to 20 mm thick are taken for the lag. Their height does not exceed 30 cm.

- For waterproofing, it is best to use special diffusion membranes. They do not allow moisture and condensation to pass through, but allow steam to pass through and prevent it from accumulating inside.

- For filing, OSB, chipboard or plywood 10-15 mm thick are used.

- If the floor suits on the ground, then for the rough layer they take crushed stone from 5 to 20 mm in size and river sand. For pouring on the bottom, you can use a ravine.

- Insulation is chosen taking into account climatic conditions.

- For the screed, concrete of the M200 grade is required. Reinforcement with metal mesh may be needed.

The choice of flooring with a good quality rough pie is not limited.

Heat insulating materials

Almost any materials are used to insulate the frame structure:

- Bulk - expanded clay. Particularly useful when laying on the ground.

- Roll - mineral and basalt wool, foam plates, polystyrene foam.

- Sprayed thermal insulation - polyurethane foam sprayed from a spray can. Expensive but effective material.

In mid-latitudes, if a "warm floor" system is installed, it is allowed to do without thermal insulation on the 1st floor.

DIY installation technology

It is not difficult to equip a rough floor with your own hands. Knowing the design of the cake and following the step-by-step instructions, you can do it on your own.

- A harness or a plank bed is installed on the waterproofing foundation.

- Fasten the lags. Fix with self-tapping screws and metal corners.

- Sheathed logs from below or from above with boards.

- Lay a waterproofing film. The material is overlapped by 15 cm and secured with tape. Each beam is wrapped with a film.

- Mats made of mineral wool or polystyrene boards are placed in the resulting cavities. The joints are sealed with tape or filled with polyurethane foam.

- The next step is to install the bars on the logs. A vapor barrier membrane is laid on them so that a gap remains between the film and the lags.

- They put a backing made of plywood, chipboard or OSB.If the floor is made of planks, they do without a backing.

The subfloor in a frame building is somewhat different from the usual one. They build it immediately after the foundation is erected, they must be insulated. Materials and construction are selected depending on the type of foundation and weather conditions in the region.