The rapid spread of suburban private construction stimulated the development of new technologies, as a result of which the range of facade finishing materials has expanded significantly. At the same time, developers give preference to materials of natural origin, characterized by high performance and a presentable appearance. An example of such a material is planking boards for facade finishing. Original options for external design are also obtained when arranging combined facades "plaster and planken".

Description and varieties of facade planken

Front planken is a standard 4-meter board with dimensions:

- width in the range of 70-140 mm

- thickness - from 1.5 to 2.2 cm.

A feature of the planken is the original shape of its section, which may look like:

- parallelogram - profile beveled at an angle of 35-70 °;

- a traditional rounded rectangle - straight profile.

A straight profile with grooves is also possible.

Materials and their features

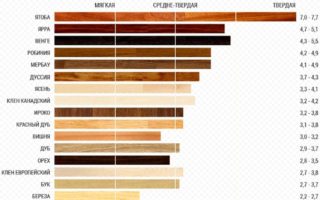

For the manufacture of planken boards, wood of various types of wood is used: teak, larch, oak, cedar, etc. One of the best materials is Canadian cedar, which differs from other types of wood in high durability, is not susceptible to high humidity, does not have parasites and does not rot. Planken made of exotic species of wood merbau, dahoma, etc. has good characteristics, however, they significantly exceed domestic planken in price.

On the market, you can also find a facade board made of thermowood - a tree that has undergone a special treatment, thanks to which all pests are destroyed in the wood. Such a board does not deform during operation, has a low weight and original texture, and also has good moisture resistance.

In addition to planken made of natural wood, on the market you can find boards made of wood-polymer composite (WPC) - facade decking.

When using cheaper materials, it must be borne in mind that each of them has a different resistance to moisture and the intensity of decay.

The choice of wood from which the facade plank is to be made is based on the climatic conditions of the region where it will be used.

Pine

The cheapest material belongs to the category of soft wood and is characterized by low moisture and heat resistance characteristics. Pine facade boards are required to be regularly treated with antiseptic preparations and compounds that protect against moisture.

Pine planken can be given an original chocolate shade. It appears during heat treatment of boards in vacuum (temperature 180 ° C). In addition to expressive structure, this procedure improves:

- moisture resistance;

- thermal insulation;

- resistance to natural aging.

Larch

Larch plank for facade – the most popular product in this market segment with an optimal price / quality ratio. Characteristics:

- high strength;

- immunity to sudden changes in temperature;

- resistance to decay.

When making planken from larch, the boards are subjected to special types of heat treatment, which increases the resistance of the material to external factors.

The larch facade is resistant to climatic and atmospheric factors, due to which it retains its appearance for a long time.

Wood-polymer composite

As raw materials for the production of WPC, products of processing of PVC products and small sawdust are used. Organic and synthetic additives, modifiers and coloring additives (pigments) are added to them. As a result, it is possible to obtain a complete visual identity of the WPC with natural planken.

Compared to planken made from natural wood, WPC has higher characteristics:

- resistant to external mechanical stress;

- retains color shades throughout the entire service life;

- does not lose shape with sudden temperature changes and with prolonged contact with water;

- fire resistant;

- does not react to the effects of chemicals (acids, alkali, etc.).

WPC is easy to cut, therefore it is suitable for facing surfaces of complex shapes.

Criterias of choice

When choosing a planken facade, you must first of all pay attention to the material from which it is made. It is best to opt for hardwood materials: oak, cedar, larch, etc. They are more expensive, but it is better to overpay once than to change the facade every 2-3 years.

Choosing the shape of the planken, it is recommended to focus on your own taste– walls finished with planken should please the eye of the owner of the house. The place where the surface is located is also important. The facade of the house can be faced with any kind of plank, but a straight profile will look best on the fence. All the rest will look pretentious or nondescript.

At the request of the customer, the surface of the planen can be given any shape, for example, rounded or wavy. This will cost a lump sum.

Not all manufacturers process their products with antiseptics, water-repellent and fire-fighting compounds. Therefore, you need to carefully consider the choice of planken, so as not to purchase an ordinary blank instead of high-quality products.

DIY facade plank installation

To clad the facade of a building with planken, you need to stock up on the appropriate materials and tools. In addition to the actual front board, you will need:

- fasteners;

- construction level;

- screwdriver;

- jigsaw.

Planken, as a rule, is mounted on a pre-filled crate. Depending on the material of the walls of the building for its arrangement, it will be useful to have:

- bars 50x50 mm or a special metal profile;

- hacksaws for wood;

- dowel screws 6x60 mm.;

- self-tapping screws for wood or nails;

- screwdriver or screwdriver;

- building level;

- drills;

- hammer;

- plumb line;

- puncher;

- antiseptic.

Arrangement of the lathing

For the lathing, it is preferable to use a metal profile that does not rot and is less susceptible to corrosion than wood.

If wooden blocks are used when arranging the lathing, they must be treated with an antiseptic.

Planken mount

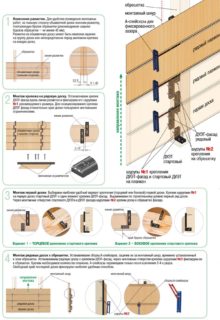

There are two ways to attach the plank to the lathing frame – open and hidden.

The open method involves attaching the cladding to the sheathing frame using decorative screws or nails. How to arrange them on the surface of the boards, everyone decides for himself.

The hidden method is carried out using specially made fasteners – "Snakes", which are flat metal plates with staggered holes.

When facing the facade with a beveled plank, it is possible to fasten the boards to the crate with self-tapping screws at the bevel points. In this case, the next board is superimposed so as to overlap the screw head.

When using a hidden mounting method, it is impossible to replace one board if necessary. We'll have to disassemble the entire facade. There are no such problems with the open method of laying.

Installation

The simple installation method is self-explanatory. To get a quality look, you just need to be careful.

The hidden cladding method requires certain skills. It is necessary to be very careful to fasten the beveled front planks of the plank with self-tapping screws along the bevels, since their thickness along the bevel is much thinner, the plank can crack.

Fastening the front plank with a "snake" is carried out as follows:

- 4 snakes are screwed to the inside of each board – two on each side.

- Instead of the first row of cladding, a 50x50 mm bar is attached, which should support its second row – this will make it possible to smoothly mount the entire facade.

- The upper "snakes" of the second row are screwed to the crate with self-tapping screws, and the lower ones remain, as it were, suspended. As a result, it turns out that the upper fastener is a small rail with holes for a self-tapping screw, and the lower – wedges for installation in the bottom row of the board.

- All subsequent rows are attached in the same way as described in paragraph 3.

- After finishing the installation of the cladding, the bar is removed from the first row, and a plank is installed in its place.

With any method of facing the facade with planken, the boards are stacked with a gap of 1.5-3 mm. This will compensate for the seasonal expansion of the timber. If desired, these gaps can be closed with special plugs that the facade planking manufacturer issues at the request of the customer.