Not every owner turns to a car service to service the car. Most people prefer to independently repair the vehicle. The equipped room allows you to perform work with high quality - the main tool is the jack. Building a do-it-yourself garage car lift will increase maintenance efficiency.

Lift types

For a personal auto repair shop, various designs have been developed - a block, a jack, a hoist, a telpher, etc. Mobile devices for lifting weights are popular.

A small jack is a mandatory attribute of a car trunk. The mechanism allows for minor repairs in any conditions. Large structures are designed for installation in a garage and are used for large-scale works.

Block mechanisms are suspended from the ceiling of the room. The devices reduce the labor costs of the operator for lifting a vehicle or other load. Depending on the number of blocks, the need for strength is leveled. For example, the presence of 4 elements installed on the ceiling beam of the garage allows a passenger vehicle to be fully raised.

Tal is a single block system. The telpher is similar in design to a combination of a hoist and a trolley that moves along a beam on top of a car. This mechanism can be equipped with motors - one for the movement of the hoist, the second for the rotation of the cable. The result is a miniature crane.

The best option for a garage lift with your own hands is a scissor or worm type of construction. This is due to performance and ease of maintenance. Making at home is a simple process.

Project part

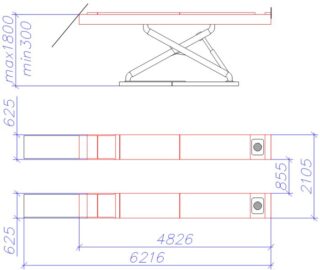

The manufacture of a car lift must be carried out clearly according to the instructions in compliance with safety precautions. The size of the equipment depends on the area of the room where it will be used. It is approximately 3.5 m high and 3 m wide. This mechanism is capable of lifting vehicles weighing up to 4 tons.

The cost of finished structures is high, however, a homemade product also requires financial investments. In addition, an improperly assembled device can cause injury or even death. In view of this, the weight of the vehicle should not exceed 1 ton.

To create a lift in the garage with your own hands, you need to prepare a design drawing or download ready-made versions. The second option should be checked for possible errors, since an incorrect calculation leads to irreversible consequences. It is recommended to consult a specialist for drawings.

The future vehicle jack is designed for a specific structure. For example, a two-column unit with an electromechanical motor is used everywhere. It consists of a threaded shaft and a bearing nut. Rotation is carried out by means of a motor.

Simple lift construction technology

Self-manufacturing implies the purchase of a set of parts and assemblies, without which it is impossible to carry out the assembly. These parts can be purchased at hardware stores. With a limited budget, it is recommended to contact scrap metal collection points and companies selling used parts.

A Chinese car lift can be bought at a price of 90,000 to 120,000 rubles. The approximate cost of a homemade lift will be 50,000-60,000 rubles.

Preparation for work

The first step is to determine the position of the pit. The vehicles installed for service should not block access to the gate or rest against the workbench. You need to build a repair pit with an accessible entrance, which will not block the open car door.

After locating and dimensioning the hoist, prepare the equipment and materials:

- welding machine;

- drills for metal;

- hand drill;

- roulette;

- steel corners 8 cm wide;

- iron plates 2 cm thick;

- worm-type gearbox.

If you have a budget and no time, contact the specialists. Mechanisms designed and manufactured by engineers comply with safety parameters.

The nuances of assembling a worm-type car lift

The presence of pneumatic or hydraulic equipment in the garage levels out injuries. In addition, such tools are pleasant to work with and make it easier to repair the machine. But if you have locksmith skills, the necessary components and time, the structure can be made independently.

To make a garage lift for a car with your own hands, you will need the following materials.

- To increase the stability of the structure, prepare steel corners with dimensions of 8x8x1 cm.

- Purchase of a new or used worm-type gearbox. The first option will be expensive, so it is better to search for disassembly or remove from a non-working installation. The lifting capacity of such a winch should be at least 350 kg, and the transmission force should be 60 kg.

- A steel plate with a thickness of 1-2 cm can be removed from an unwanted or old product. Additionally, you will need bolts, hooks and sprocket keys.

- Iron chains are selected with a minimum ѳ2 cm. Weak fixtures will not withstand the load. Experts point out the need to check the quality of the product, since a number of materials are stretched during operation.

- Steel rope from 5 mm.

The simplest unit involves an I-beam or a conventional bracket with a winch. However, such units are not profitable from a commercial point, since the owners of premium vehicles are suspicious of such designs.

Sequence of assembly and assembly of units:

- Attach the steel corners to the walls opposite the vehicle hood.

- Fix a 2 cm thick slab from above.

- Use bolts for connections.

- Install the worm gear by keying to the drive shaft.

- Fit the small key ѳ on the output shaft of the gearbox.

It is recommended to mount the unit on M18 studs, the length of which is at least 30 cm. In the lower part, a metal plate with a thickness of 3-5 mm is fixed.

The creation of a stopper deserves special attention. The devices protect the operator from abnormal situations. The mechanisms should be checked before and after using the lift. In particular, the nuts on the electric drive are monitored.

Installation features

Correct selection of the lifting mechanism for the garage does not give 100% for the correct operation of the structure, since the product must be installed with high quality. For these purposes, it is necessary to equip the base. For lifting equipment, a concrete foundation with a thickness of at least 10 cm is required. Additionally, the base is reinforced. Without this stage, there is a risk of dismantling the structure and re-pouring the foundation according to technical recommendations.

When buying a garage, check with the owner for the thickness of the screed and base. In this case, the rule of compatibility of the parameters of equipment and premises applies.

The arrangement of the garage and the technician for the repair and technical inspection of the car require a detailed approach. In the absence of knowledge about the types of equipment, as well as work skills, it is better to entrust the construction to experts.

Technique for safe operation of the lift in the garage

- dismantling of motor fasteners, bolts and nuts;

- supply of steel cable loops for coupling mechanisms;

- rotation of the drive shaft by busting the chain;

- slow rise of the part to the desired height.

After fixing the part, the transport is removed from the repair site. A table is placed under the engine. The stand can also be made by hand. The main thing is to create a solid structure designed for the appropriate loads. The best is a mobile table on wheels, which allows you to move the part in the desired direction.

Repairing large cars in the garage is not uncommon. However, not every mechanism is designed for wheel diameter and ground clearance. Therefore, to service such vehicles, an assistant is needed who will pull the winch to install the spare part on the prepared stand. At the same time, the second person rotates the gearbox.

Maintaining the device in working order consists in regular inspection of the main components - fasteners, help areas, wiring, racks. During operation, do not violate the permissible vehicle weight.

Vehicle repair shops cannot do without a lift. Which one is better to choose is decided by the owner of the station or the owner of the garage. A variety of models from Russian and foreign manufacturers are presented on the market. For example, an installed elevator for a vehicle pays for itself in 6 months, but buying such a unit for personal use is impractical. Given your own skills and the availability of drawings, you can build a car lift yourself.