The fence serves as a decorative function, and also protects the house from the prying eyes of strangers. Natural and artificial materials are used for its manufacture. It is much easier to make a fence from a Euroshtaketnik with your own hands than other options. The work does not require special preparation, but you need to make the correct markup, select the material and calculate its amount.

- What is Euroshtaketnik

- Advantages and disadvantages of a metal picket fence

- Types, forms, profiles

- Dimensions and distances

- Calculation of the required amount of material

- What to look for when choosing a material

- Necessary tools for work

- Preparatory work

- Installation of supports

- Assembling the frame of the fence from the picket fence

- Features and installation rules

- Types of fillings

- Color options

What is Euroshtaketnik

The picket fence is a narrow profiled element made of thin galvanized steel sheets. The material is passed through a machine with ribbed rollers and then cut. Do not confuse it with corrugated board.

By design, such a fence is similar to a wooden one. Distinguish between material by design and aesthetic properties. They use it for fencing suburban residential buildings, summer cottages. The standard thickness of the elements is 0.4 mm.

Advantages and disadvantages of a metal picket fence

The selected material has the following advantages:

- resistance to moisture, thanks to a polymer protective coating;

- lack of processes of rusting, decay;

- fire resistance: metal does not burn;

- small mass, which allows you not to build a heavy foundation;

- high level of decorativeness;

- durability of the polymer coating;

- good combination with other materials: ease of installation, which does not require special construction skills.

The disadvantages include the high cost of the picket fence, the need to use press washers, which are more difficult to tighten, the increased risk of injury during installation if the elements are not rolled. Low degree of vandal resistance.

Fences made of euro shtaketnik are distinguished by high strength, resistance to deformation under the influence of moisture and temperature extremes. Elements do not need to be painted periodically. Replacing damaged pickets with new ones is not difficult. They are used for fencing not only houses, but also flower beds, gardens, lawns.

Types, forms, profiles

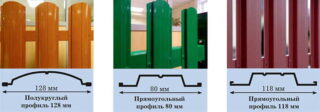

To make a fence near a house from a metal picket fence, you need to choose the right type of it. The profile is rectangular (U-shaped), semicircular and M-shaped rolled and classic. The latter type is more durable, since it has more stiffeners. Semicircular options are more expensive and more difficult to form.

Varieties:

- Nova. It has a 16-rib shape, up to 11.5 cm wide. The top layer is a polymer protective coating. The surface is glossy or matte.

- Light-M. A lightweight version with a width of 7 cm.It can be bought at any hardware store.

- Ekonova. A durable material with a large number of ribs, a panel length of 1-2 meters and a width of up to 10 cm.

- Barrera. Differs in powder-polymer coating. Metal staples are required for fastening.

The best coating for the elements is polyester.

Dimensions and distances

The thickness of the planks is 0.4-1.5 mm, the width is 8-12.8 cm, and the length is up to 2 m. To enclose the site, the planks are installed at a certain distance from each other.This indicator depends on the preferences of the owner. Most often it is 35-50% of the element's width.

When fastening the planks with a checkerboard, they should overlap half the width of the element. In this case, the yard will not be visible at an angle. For maximum concealment of the territory of the site from prying eyes, you can use a picket fence 180 cm long.More often, elements of 1.25-1.5 m are used in construction.

The width of the span usually does not exceed 2-2.5 m. At this distance, supports are mounted, on which 2-3 crossbars are attached.

Calculation of the required amount of material

If it is necessary to install one row of Euro shtaketnik with gaps, to calculate its quantity, the length of the fence (L), the distance between the elements (M), the width of the panels (S) are required. To get the result, you should use this formula: K (quantity) = L / (M + S). If a decision is made to make a double-sided fence, then the value is multiplied by 2. It is advisable to add 10-15% of the material in reserve when buying.

To determine the number of cross bars, the total length of the fence is multiplied by two. Additionally, the width of the supports is taken into account.

What to look for when choosing a material

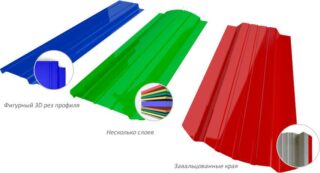

Before making a fence from a metal picket fence with your own hands, you need to choose it correctly. For this, the following factors are taken into account:

- Material batch. It is better to review all the elements at once in the store, since pickets of different thicknesses can be in different packages.

- The presence of a rolled edge. In this case, the planks have an attractive appearance and become safer to use. Such bars are more rigid.

- The presence of several protective layers.

- Quality certificate.

- Brand.

Pay attention to the color of the material.

Necessary tools for work

To install a picket fence, you will need the following tools:

- tape measure, cord and wooden stakes for marking the site;

- hand drill for making holes for supports, shovel (if it is planned to erect a strip foundation);

- welding machine for connecting poles with crossbars;

- drill, screwdriver (if self-tapping screws for metal are used for fastening) with a cruciform nozzle;

- building level, plumb line;

- riveter;

- manual or electric scissors for cutting metal;

- concrete mixer.

It is required to assemble profile pipes of different cross-sections from additional materials for the installation of pillars and fastening of crossbars. You need a primer, self-tapping screws with rubber gaskets for the roof (the head must have the color of the finishing material). To install the supports, sand, gravel, crushed stone, cement, reinforcement are required. For facing the pillars, tiles or clinker bricks are used, which must be fixed with special glue.

Preparatory work

Preparation includes the marking of the site. For this, a drawing is preliminarily prepared, on which all measurements are indicated. According to the scheme, wooden stakes are installed in those places where the supports will stand.

All tools and materials must be prepared for work. During the marking, the location of the gates and wickets, the location of the pickets are taken into account.

Installation of supports

To install the pillars, you can dig holes at the markup points or make a concrete foundation. The second option is suitable for high fences, the load from which is greater. When choosing the first method for installing supports, the following procedure is provided:

- Drilling a hole. Its diameter should be 10-15 cm larger than the pipe circumference.

- Sand and gravel cushion making. The total layer is 10 cm. The pillow is moistened and tamped.

- Installation of pillars. For this, pipes with a diameter of 5-10 cm are used. Wider elements must be placed at the corners of the structure. All supports are aligned vertically and driven into the ground with a sledgehammer. After that, the post is fixed with props.After installing the pipes around the perimeter, the thread is pulled between them and the remaining elements are installed.

- Concreting. First, a third of the pit is filled, after which the mixture is compacted. Then the solution is poured twice more, 1/3 depth.

If the site is uneven, you can use a pile foundation or remove excess soil.

Assembling the frame of the fence from the picket fence

To build a picket fence, you need to build a frame of vertical and horizontal elements. For crossbeams, pipes with a length of 1.5-2 m are chosen. The wall thickness is at least 2 mm.

They are placed strictly parallel to each other at right angles to the supports. The correctness of installation is checked by the building level. The crossbars are fastened by welding in 2 rows.

The configuration of the fence is different. It provides for the arrangement of decorative elements at the same level, at an unequal height (a wave is formed), in the form of a herringbone (the central plank is the highest, the height of the rest gradually decreases towards the supports).

If the staggered installation method is chosen, the fence will not have a seamy side and a front side. However, the consumption of finishing material increases. The elements themselves can have a straight edge, an angle, or a trident. To make the design original, a semicircle can be cut on each panel.

Features and installation rules

To install the fence correctly, you need to take into account the following features:

- it is better to use a profiled pipe for supports;

- the crossbars are fastened so that 25-30 cm remains to the edge of the post;

- when choosing fasteners, it must be borne in mind that self-tapping screws are twisted easier and faster, and rivets provide greater strength of the connection.

When choosing the shade of the fence, you need to take into account the general design of the site and the residential building.

Types of fillings

When attaching pickets, several methods are used to fill the spans:

- straight (all elements have the same length);

- wavy (the planks are cut at a certain distance).

The second option is more difficult and involves more waste.

Color options

The painting of the picket fence is one-sided and two-sided. In the first case, the inside of the fence will be the wrong side (gray). In the second, the color is the same on both sides of the plate. Polymer and powder coatings are distinguished by type. The first type is more reliable, and the application of the layer is possible in a production environment. Powder paint will adhere well to a previously primed surface. However, you can apply it yourself.