A standard hinged sash requires space to open. You cannot put furniture or hang curtains next to such a door. Do-it-yourself sliding doors solve this problem. There are several design options for this device and many ways of implementation.

Sliding door systems

Sliding doors differ from swing doors in the way they are opened. At the same time, the sash moves along the facade and does not take up additional space. The design is used both in furniture - a wardrobe, and as interior doors or a screen in a niche.

The sash opening ensures the movement of the rollers along a special track with grooves. This method ensures ease of opening and smooth movement even with a large sash weight. On the other hand, such a mechanism presupposes the presence of technological gaps and the impossibility of a tight junction of the sash. It is installed from the wall at a distance equal to half the width of the guide, and there is no door frame at all. Therefore, the heat and sound insulation of interior sliding doors leaves much to be desired.

A big plus of such a system is the freedom of choice of material and decor. The frame or profile gives the door leaf stiffness, and the guide system itself gives the vertical position. As a result, for a sash, you can take materials that are completely unsuitable for a swing one - polycarbonate, mirror, leather.

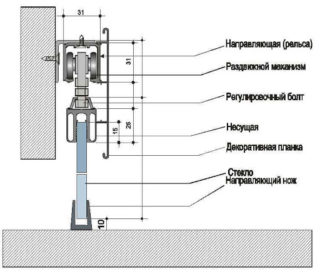

Suspended on the top rail

A one- or two-way sliding system is fixed to the wall in the upper part of the room or to the ceiling. The bottom rail is missing here. The displacement is carried out by the movement of large rollers in the upper rail. The same mechanism ensures the vertical position of the door leaf, that is, the upper carriages have a double load.

This feature limits the choice of material. It is allowed to install light, small sashes. Otherwise, the fittings fail and the door warps under its own weight. But you can't put too light ones: it sways in a draft.

In order for the sash to slide easily without lower rails, it is placed at a certain distance from the floor. Such an interior door does not provide sound or thermal insulation.

Sliding rail

The two-lane system includes a bottom rail and an top rail. The door leaf rests on the lower rollers and moves due to their movement along the grooves. Upper rollers keep the sash upright. The design, especially if it is an interior partition, is equipped with movement limiters at the bottom, and feet at the top. In a wardrobe, you can do without both elements, although stoppers are usually installed.

The two-lane mechanism is much more reliable and durable. Here you can put heavy doors made of solid wood, mirrors, thick silicate glass. Another plus is better heat and sound insulation, since the mechanism includes fewer technological gaps, and the adjoining density can be increased due to seals.

Do-it-yourself installation of a sliding double-leaf door is more difficult and takes more time.

If the sashes are very heavy, double guides are installed for each leaf.

Sliding door mechanism

The roller door mechanism consists of guides and rollers with carriages. The latter constitute a retractable block and are the most important structural element. The system is supplemented with limiters that prevent the sash from coming out of the grooves, stoppers and decorative plugs.

There are 3 options:

- Synchronous - both sashes move apart in different directions, moving along the wall. Installation of the system is complex and requires a lot of effort to synchronize. The package includes rollers, rails, hooks, cable and fasteners.

- Telescopic - 2 or more leaves are displaced to one side, closing the facade or another leaf. Each element moves on its own rail. This system is typical for a wardrobe. Disadvantage: for 2 doors, you need to install 2 rails with a total thickness of 14 cm. For a three-door structure, you will need a guide with a width of 21 cm, which is already inconvenient.

- Tram - option for a folding model. Usually equipped with a locking mechanism.

The fittings for the mechanism are selected by the type of construction and by the weight of the sash.

Advantages and disadvantages

Sliding interior doors have many advantages:

- The sliding system saves space as no space is needed to open the sash.

- Ease of handling: pushing even a very heavy sash is easier than opening.

- Sliding doors are used not only as interior doors. With their help, niches are blocked, the room is zoned.

- The design is much more original and varied.

There are also significant disadvantages:

- The main disadvantage is poor heat and sound insulation. There is no possibility of tight joining of the door leaf with a wall or frame.

- A two-way system is more reliable. However, for it on the floor, it is required to mount guides with a total width of 7 to 14 cm. Such a sill is very inconvenient.

- Constipation on such a model cannot provide protection.

The variety and decorative possibilities of sliding doors compensate for the disadvantages.

Varieties of guides

For sliding interior doors, a guide is important. It is a U-shaped profile with stops. Its standard width is 7 cm, height - no more than 3 cm. The rail is made of metals:

- Aluminum is a lightweight, corrosion-resistant metal. Such a profile wears out little, does not need maintenance or protection, has its own pleasant color and shine. However, its mechanical strength is relatively low. Aluminum rails are only suitable for lightweight sashes.

- Steel is stronger and more durable. Serves up to 50 years. Steel hardly wears out. However, it is prone to corrosion, in order to protect the profile from rust, the steel is coated with a layer of zinc, chromium, varnish, polymer paint. The integrity of the coating must be monitored.

Other factors are also taken into account:

- type of roller system and method of opening;

- the number of parallel moving canvases - this is how the number of guides is calculated;

- the nature of the sash support - if it is a single-lane system, then the upper rail must be reinforced, as it is subjected to double loading.

The lower rail, even if it is "drowned" in the floor, remains visible. Therefore, when choosing, you need to evaluate its design.

Mounting options

Parallel sliding doors can be installed in different order. This affects the design of the mechanism and the material of the flaps.

Sliding doors

The most famous option. The sash moves along its guide in both directions. If the design is two-leaf, the leaves move towards each other. They have a common guide. This is the best option for simple interior doors, since only 1 rail will have to be mounted on the floor, and its width is only 7 cm.

Cassette

With this opening mechanism, the doors look much more interesting. When opening, the sash does not move along the wall, but inside it. For this, a cavity is formed in the partition.If this cannot be done, a false wall is erected. In this case, the sash really moves along the real wall, but disappears from view in a plasterboard box.

The design can be one or two doors.

Cascading

A telescopic opening mechanism is implemented. Each sash moves along its own guide in one direction. For a two-door structure, you need to install 2 rails, and for a three-door structure, 3.

Cascading doors are more suitable for a wardrobe. However, with a complex configuration of adjoining rooms - a box on one side, a large difference in the thickness of the walls and interior partitions - this option turns out to be more convenient.

DIY installation

To install a door made of chipboard, polycarbonate, plastic panels, you do not need to resort to the help of specialists, but follow the instructions. The main condition is to give the sash a vertical position. Therefore, in addition to a screwdriver, hammer, chisel, you need to prepare a construction level and a plumb line.

Installation diagram:

- Cut the profile: the lower guide for a single-door structure should be 2 times the width of the doorway. They are installed so that the sash completely clears the opening when opening. In this case, on the other hand, 50 mm is left near the opening.

- For a door structure, the guide is mounted so that its middle coincides with the center of the opening.

- Holes for dowels are drilled through the rail in the floor. Insert the dowels and fix the fasteners.

- Determines the position of the upper rail. To do this, install a canvas in the lower rail and mark its edge on the wall. Add to the value 70 mm and make a mark, check the horizontal level with the building level.

- A wooden beam with a cross section of at least 50 * 50 cm is fixed at the mark. From the bottom, the upper rail is fixed to it in the same way as the lower one.

- Stoppers and other additional elements are installed.

- The door leaf assembled according to the drawing is introduced into the guides: first in the upper rail, since the upper pressure rollers, then in the lower one. Check the vertical position and freedom of movement.

- A decorative strip that overlaps the beam and the upper guide is fastened.

It is recommended not to fix the top rail immediately. If the flap does not move well, you can correct its position by changing the position of the upper rail. The final fixation is performed by achieving free displacement.

Homemade sliding doors

Even a sliding door can be made from an ordinary door.

Manufacturing recommendations:

- If the door leaf weighs less than 30 kg, a suspension system can be installed. If more - put a two-lane.

- An interior door made of chipboard often has decorative inserts or overlays. If you cannot remove them, you must take their dimensions into account when locating the bottom rail. Otherwise, the sash will not be able to go onto the wall.

- The usual fittings are removed. It is inconvenient to move the sash using the round handle.

- The accessories are bought taking into account the weight of the product. Door handles - tailored to the design.

- The material is preferable lightweight, but durable: chipboard, MDF, polycarbonate. Mirror and glass are much harder to work with.

- The balance of a conventional sash is not designed for this use. To compensate for this, the rollers are placed as far apart as possible to ensure a smooth ride.

Sliding doors are practical and comfortable. They do not take up space when opening, they are very decorative and easy to use. However, their heat and sound insulation performance is lower than that of swing doors.