The owner of the site understands the need for utility rooms already before the start of construction. You can easily build a budget shed with your own hands. It is important to choose the right project and take into account the peculiarities of working with various building materials.

Features and requirements for construction

It is customary to call a barn a covered unheated structure for keeping animals and storing various property. In the classical sense, the barn project does not provide for an overlap between the room and the roof. For ease of use, increasing the usable area in some cases, the attic is still done. This, for example, allows you to store stocks of hay or snow removal equipment during the warmer months.

You can build a barn in the country without applying for permission from supervising authorities. However, in the future, it is worth registering the structure in the proper order.

Capital outbuildings on the site (in addition to a residential building) are not taxed if their total size does not exceed 50 m². This parameter is taken into account when designing.

When placing on a site, town planning norms established by local authorities and fire safety rules are taken into account:

- the structure must be located strictly within the site;

- the distance to the fence with neighbors is at least 1 meter if the roof slope is directed towards its territory and at least 1.5 meters from the overhang line, in the case when water flows towards the neighboring territory;

- choose a distance of 5 meters to the road and leave 3 m for a fire break;

- a shed for animals and poultry is placed no closer than 4 m from other buildings and the border of a neighboring site;

- a wooden shed is allowed to be placed no closer than 6 m to a house made of bricks and similar materials, no closer than 8 m, if there are wooden floors in the building and no closer than 15 m from wooden residential buildings;

- to toilets with cesspools, a distance of at least 10 m is left.

When starting to design, it is worth remembering that the purpose of the building may change over time. For example, a building shed can be used for keeping poultry or livestock, and later for a workshop. Therefore, they pre-lay such a characteristic as universality.

At the stage of building a house, the price is important; in this case, a budget material for the construction of walls is chosen, for example, wood. Sometimes a croaker is used. After using bricks, pallets and pallets remain on the farm. They are taken apart, and the boards are used for wall cladding.

Basic construction technologies

All shed designs can be divided into three groups: monolithic, frame, modular.

Monolithic buildings imply the construction of walls made of bricks, expanded clay and foam concrete blocks, natural stone. The option from a log or a bar is possible. The structures are durable and versatile in use.

The construction of a shed can be accelerated by using large cinder blocks or foam blocks for the walls. They are lighter than bricks, therefore, they have less requirements for the strength of the foundation. At the same time, larger elements are easier to stack and align.

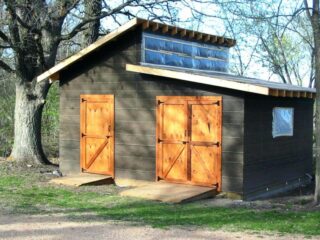

Popular is frame technology construction. In this case, the skeleton frame is sheathed with various materials: boards with OSB panels, clapboard, profiled sheet or siding.

For wooden sheathing, the frame is prepared from a bar, for a profiled sheet from metal-profile pipes. It is important that the temperature coefficient is approximately equal for the frame material and the sheathing material. Otherwise, with strong temperature changes in winter, fasteners will collapse.

The advantage of the technology is the low weight of the building and in some cases it is possible to do with a light foundation or put the shed on horizontal joists.

The construction speed is due to the fact that each sheathing sheet covers a large area of the wall.

Modular the technology provides for the preparation by the developer of the base for finished factory products such as a trailer.

Choice of layout

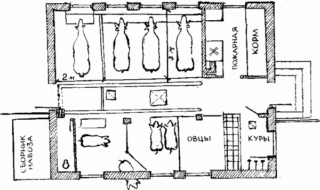

Before the start of construction, they clearly think over the purpose of the structure and the possibility of its re-profiling. The option can only provide for the maintenance of livestock or be used for a change house, workshop, warehouse.

It is advantageous to build a universal shed when different rooms are combined under one roof. For example, a cow shed can be combined with a woodshed and a hayloft. At the same time, there is no need for a large shed in the country if the building is needed only for storing tools and equipment.

The layout is drawn on paper or an empty piece of land is marked out according to the exact dimensions - this way it is easier to understand whether it will be convenient to use the building.

Many projects can be found on the network at the specialized forums of summer residents and livestock breeders.

Based on the sketch, a project is developed, according to which the calculation of materials is carried out.

Types of foundations

Construction begins with the arrangement of the foundation. There are several options available to suit different buildings.

Tape

For capital buildings, shallow strip foundations are very popular. They are used on light soils that are not heaving.

Main advantages:

- requires a minimum amount of earthwork;

- construction is carried out with one assistant or alone;

- withstands the weight of any building material.

From the tool you need:

- bayonet and shovel;

- a concrete mixer will speed up the construction, but you can also mix the solution manually;

- grinder for cutting fittings;

- hacksaw for wood;

- hammer, ax, nails;

- tape measure and marking cord.

Reinforcement is carried out with a 12 mm rod, metal or polymer. For formwork, boards will be needed.

Prepare cement, sand and crushed stone for cushion and concrete.

Construction algorithm:

- Level the site, free the surface from construction and other debris.

- They dig a trench to a depth of 50-60 cm, the width is chosen 40-50 cm more than the foundation itself. The stock is needed for the convenience of installing the formwork.

- They fall asleep at the bottom of the trench with crushed stone mixed with sand, spill a pillow with water and ram it.

- Fittings are mounted. The minimum number of longitudinal bars is two, one above the other. For full-fledged walls with a thickness of 25 mm or more, there should be 4 longitudinal rods. Every 40–50 cm, transverse and vertical segments are screwed to the longitudinal reinforcement with a knitting wire.

- Install the formwork. If an unedged board is used, then the shields are sewn up from the inside with roofing material, plastic wrap or fiberboard sheets - this will prevent concrete from leaking out.

- Pour concrete grade M150 or M 200. Approximate proportions of the mixture: cement, sand, crushed stone: 1: 2.5: 3.5. To eliminate voids, compaction is carried out as it is poured.

The pouring is carried out within one day, so the maximum strength will be achieved. If it is impossible to mix the required amount of solution on your own, then buy a factory-made mixture.

In hot weather, the finished foundation is covered with plastic wrap to prevent rapid evaporation of moisture and cracking of the foundation.

On heaving soils in the corners and intersections of the tape, recesses are dug below the freezing level.They are reinforced and poured with concrete at the same time as the main tape.

Platen

Slab foundations are suitable for all types of soil.

The base carries the weight of the walls, the roof and serves as the base for the shed floors.

Construction instructions:

- They clean the area, remove the roots of plants.

- A pit 20-30 cm deep is being dug over the entire area.

- Fill in a pillow of sand and gravel, 10-15 cm thick.

- Reinforcement is carried out with a bar from 10 mm with a lattice pitch of 15x15 cm.

- Formwork is built with a height of 20-30 cm.

- Concrete is poured, the mixture is leveled. The level should be 15–20 cm above the ground.

- Cover the surface with a film, and in hot weather, pour water over the concrete every 3 hours, which will prevent cracking.

It is possible to erect stone (brick, block) walls in 28 days, when the concrete will gain full strength.

Columnar and pile

The foundation on poles and piles is similar in design and principle of operation. To a depth below the freezing of the soil, piles are screwed in or load-bearing pillars are built (poured).

The surfaces of the elements are aligned horizontally and the logs are supported on them, which are the basis for the walls.

The foundations are suitable for any type of soil, including those prone to heaving.

In addition to the support log, a grillage can be poured or bricked between the piles, which will strengthen the structure and protect the building from being blown by the wind.

In regions with light soils, the pillars can be deepened by 50-60 cm. Such a structure is suitable for temporary buildings, but it can stand for 10 to 15 years.

Sheds without foundations

You can build a wooden shed without a foundation. For this, a frame is built, which is sheathed with any material.

The racks are supported on the ground or laid in the base of the logs from the timber.

Construction of a frame shed

The frame is erected on a completely frozen foundation or on a lower log laid on the ground. In both cases, work begins with waterproofing. Well, the foundation is laid with roofing material or roofing felt in 2 layers. Material must extend beyond the bottom support bar.

For the lower beam, choose a bar with transverse dimensions of at least 100x100 mm.

The lower harness is attached to the foundation with threaded rods, which are poured simultaneously with the foundation or screwed into threaded anchors. The fixing step is 1–1.5 meters.

It is more convenient to assemble the frame of each of the walls on the ground, and then lift and fix it in an upright position.

For a pitched roof, the walls should be of different heights, providing a slope of 10 °.

When working alone, each post can be installed separately, secured in the desired position with slopes. After installing the vertical supports, they are connected with horizontal crossbars. Fastening is carried out with nails or using a galvanized corner and self-tapping screws.

The distance between the vertical posts should not exceed 1.5 meters, and 60–80 cm is considered optimal, which will correspond to the distance between the roof rafters - in this case, the maximum structural strength is achieved.

Before the wall cladding begins, the racks are reinforced with inclined jibs so that the vertical installation is observed.

The upper edge of the frame is made of longitudinal beams. Horizontal cross members are installed taking into account the window and door openings.

Roof frame

Sheds in most cases are covered with shed or gable roofs. The first option is easier to install, the second allows you to get more interior space. The rafters support the upper longitudinal beams. The placement step is from 60 to 80 cm.

With a large length, the rafters are additionally supported on the girders. The logs are connected with battens, on which the roofing material is laid.

A gable roof is made on layered or support beams. Slate, ondulin, roofing sheeting, soft tiles are used as roofing material.

Frame sheathing

The construction of the shed continues with the frame cladding.From the outside, flat slate, edged boards, metal profiled sheets or any type of siding are nailed or fastened with self-tapping screws.

Internal walls, depending on the purpose, are sheathed with plywood, boards, clapboard, OSB panels.

If you put insulation between the racks, the shed will be comfortable for keeping animals or arranging a year-round workshop.

Windows and doors

The frame house settles down within 4-6 months. At this time, do not insert the windows of the door, which can jam or even destroy.

In the future, windows and doors of any design are inserted.