The problem of multi-storey buildings of all types (block, brick, panel) is the low level of sound insulation of interfloor ceilings. Steps, falling objects, talking or moving furniture in the upper apartment interfere with comfortable rest. Soundproofing the ceiling will help protect against them. The work can be combined with the renovation of the apartment. A tension or suspended structure will update the design of the room.

- Common methods of soundproofing the ceiling

- Classification of modern soundproofing materials

- Mineral wool

- Particleboard and fiberboard

- Bung

- Styrofoam

- Acoustic foam rubber

- Design options for sound insulation

- Frame systems

- Frameless systems

- Required tools and materials

- Do-it-yourself ceiling soundproofing features

Common methods of soundproofing the ceiling

Different types of noise propagate from the top of the apartment through the voids of the interfloor ceilings:

- shock - falling objects, stomping;

- structural - power tool operation, fan;

- acoustic - loud speech, music.

In order not to hear the neighbors making noise, it is best to install multi-layer soundproofing of the ceiling. There are several ways to get the job done.

- Stretch ceilings - PVC film or fabric trim is stretched onto a special profile fixed to the walls. There remains a free space in which communications and soundproofing of the ceiling under the stretch ceiling are hidden. Frame and frameless technology is used.

- Suspended ceilings - a design feature is fixation to the ceiling without suspension. As a finishing material, gypsum plasterboard or gypsum fiber sheets, MDF, chipboard, plastic are used.

- Suspended ceilings - the structure consists of a frame and decorative material, it is attached to the main ceiling through a suspension system. By type, they are cassette, rack or solid. Suspended ceilings are compatible with any sound insulation.

The device of the ceiling structure with the use of noise-absorbing materials is a partial sound insulation. The system achieves maximum efficiency when using a combination of several products.

Classification of modern soundproofing materials

The level of noise absorption depends on the characteristics and characteristics of the materials used. When choosing products, their thickness, flammability, safety for human health are taken into account. All sound insulation is divided into 3 types:

- Soft - rolled or slab products with a fibrous structure - mineral wool, felt. They absorb sounds better than other types - up to 90%. Of the minuses - for effective work, a thickness of 50-100 mm is required.

- Semi-rigid - slabs with an elastic cellular structure (foam, polyurethane foam) retain 50-70% of noise.

- Rigid - slabs of minerals (vermiculite, perlite, pumice) absorb up to 50% of acoustic vibrations. Their plus is their small thickness.

The sound insulation index is measured in decibels and can be found in the product labeling.

Mineral wool

A fibrous material based on melted basalt or glass is able to reliably soundproof a room. The loose structure of the mats allows the absorption of acoustic waves. Basalt wool is durable, safe and durable. Plates are treated with water repellent impregnation and are not afraid of moisture. Flame retardant material, prevents the spread of flame. Installation of mineral wool is simple, it is laid between the frame guides.When working with glass wool, protection against spiky fibers is required. Fiber boards are excellent insulation materials.

Particleboard and fiberboard

Waste from the woodworking industry is used as a raw material for the production of boards. Chipboards have a loose structure to help dampen noise. Their thickness is 8-40 mm, the sheets are used when installing false ceilings. When choosing a material, the emission class is taken into account. Fiberboards are made from wood dust mixed with synthetic fibers and polymeric substances. After pressing, dense and thin slabs are obtained. Fiberboard is recommended for use in dry rooms. Wood-based panels increase the level of thermal insulation.

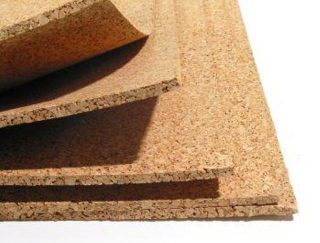

Bung

Soundproofing on a cork ceiling is an expensive but effective option. The material has a cellular structure that dampens up to 85% of sound waves. The cork cover is completely natural, it is created by pressing the crushed bark. Products are strong, moisture resistant and durable, low thermal conductivity allows you to simultaneously insulate the apartment. The price per square meter depends on the thickness of the cork board. On the ceiling, the coating is glued.

Styrofoam

The cellular structure of the foam provides absorption of acoustic waves and low thermal conductivity. The material is resistant to biological effects and moisture, and has been used for decades. Its main advantage is its budgetary cost. The disadvantages include the required thickness of the plates from 50 mm and the release of toxins during combustion. The foam will be replaced by extruded polystyrene foam. It has improved performance so that a thinner material can be used.

Acoustic foam rubber

The sound-absorbing material with an open cell structure does not contain harmful components. The foam rubber is lightweight and easy to install. It is fixed to the ceiling with special glue; some boards are produced on a self-adhesive base. Disadvantages of this option: high cost and flammability.

If the ceiling in the apartment is low, roll sound insulation will be the best option:

- Texound is an elastic mineral membrane 4 mm thick. High density and high weight canvas effectively absorbs acoustic waves. The membrane is waterproof, is not afraid of biological effects, has an unlimited service life. It is attached to the base with glue.

- Noise block - loaded vinyl has a thickness of 2.5 mm, but is very heavy. A flexible membrane allows you to create a thin frame system for soundproofing in an apartment.

The choice of material depends on the type of noise, financial capabilities and preferences of the apartment owners. Specialized products (acoustic membranes) perform only the main function, mineral wool and foam at the same time insulate the apartment.

Design options for sound insulation

Insulation of interfloor floors is performed by frame and frameless method. The first option is more effective due to the placement of a greater thickness of soundproofing materials. The frameless method is faster and cheaper.

Frame systems

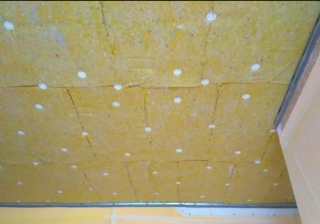

The technology requires the installation of a lathing lathing or assembly of a frame from a metal profile. Components of the structure are: soundproofing filler and durable cladding material (plasterboard, gypsum fiber sheets). To prevent the propagation of impact noise, vibration isolating suspensions and gaskets are used. The method is a standard assembly scheme for false ceilings, supplemented by soundproofing. The frame system performs the function of heat and sound insulation, allows you to create an original interior in the apartment.

Frameless systems

Noise insulation of the ceiling in an apartment under a stretch ceiling can be done in a frameless way. This method allows you to maximize the height of the room. Suitable for work are hard slabs of basalt wool, expanded polystyrene, cork. The sheets should have a density of 40-45 kg / m3. Soundproof ceiling boards are fixed with glue and plastic disc dowels.

Installation is carried out on a clean and primed base. The adhesive composition is spread over the slab with a spatula, then it is firmly pressed against the ceiling. For secure fixation, 5 plastic dowels are hammered - 4 at the edges and 1 in the center. Plates are laid close to each other, the seams are filled with sealant.

When installing a frameless system, it is recommended to use ZIPS - sandwich panels consisting of mineral wool and drywall slabs. They have vibration-isolating attachment points, as well as grooves and ridges for docking with each other. A damper tape is attached around the perimeter of the ceiling. ZIPS panels have holes for mounting. Fastening is carried out with plastic dowels.

Required tools and materials

To install the suspended structure and soundproofing panels for the ceiling, you will need:

- puncher;

- screwdriver;

- roulette;

- laser level;

- cord for marking;

- stationery knife;

- scissors for metal;

- galvanized metal profile;

- vibro suspensions;

- sealing tape.

Starting and finishing putty is used as a finish for drywall. To prevent cracking, a fiberglass reinforcement mesh is laid.

Do-it-yourself ceiling soundproofing features

The installation of soundproofing of the ceiling should be carried out according to the technology, only the correct arrangement of the elements will provide the desired effect.

- Preparation of the base. All cracks are sealed with cement-sand mortar. The surface is cleaned of dirt and old coatings. The shelf is treated with soil.

- Markup. With the help of a laser or water level, markings are made for the guide profile.

- Collecting the metal frame. Vibration suspensions are installed in the designated places. The metal profile is cut to size. So that the sound does not pass through the metal, you need to soundproof the guides by gluing a special sealing tape on the back. The distance between the elements is equal to the width of the slabs to be laid (40-60 cm). The ceiling profile is fixed with hangers, the guides on the walls are screwed in with self-tapping screws. The cross members are fastened with connecting pieces. The horizontalness of the frame is checked by the level.

- Basalt wool slabs fit into the formed cells. An incision is made in the right places to output the wiring.

- After laying all the soundproofing material, it remains to make the sheathing with plasterboard sheets at random. This will require a screwdriver and self-tapping screws. Seams between the sheets are sealed with a sealant.

The best option for creating acoustic comfort in an apartment is a frame structure with plasterboard sheathing and soundproofing filling made of mineral wool slabs.