The floor on the loggia with your own hands needs to be equipped taking into account the design features of the room. The correct installation of the coating and its selection in accordance with the operating conditions is important.

Features and designs of balconies

Before making the floor on the balcony, you need to study how these rooms can differ among themselves and what restrictions this imposes on the choice of material. Using the coating in unsuitable conditions leads to its rapid deterioration with the need to dismantle it.

Open

An unglazed balcony is the most demanding of the material's resistance to environmental factors. The coating must be waterproof (including not deteriorating from icing), not fade from ultraviolet radiation, tolerate temperature extremes and frost, and be easy to clean. It should not allow moisture to pass into the underlying layers.

Closed

Balcony flooring can be done using a wider range of materials. Limitations are imposed only by the factor of temperature jumps - it is not recommended to use laminate in such a room. Also, carpet is not suitable in this case - if the balcony is not heated, condensed water collects in the pile. Other popular coatings can be used safely.

Insulated

If the balcony is used for hanging linen and storing household items, and it is not planned to glaze it, there is no need for insulation. In a closed room, when installing the floor covering, it is recommended to lay a thermal insulation layer. This will extend the life of the material and increase the comfort of the residents, because reinforced concrete slabs tend to accumulate cold. Sometimes a warm floor is also used - in this case, you can stay on the balcony for a long time in the cold season without the risk of catching a cold. As a rule, the work will be carried out simultaneously with the leveling of the surface.

The installation of flooring, especially ceramic tiles, puts a certain load on the slab. In rooms with heavy coatings, it is risky to put large furniture or go out in a large company. You can calculate the load using a special online calculator. The volumes of the room and the height difference are entered into the fields, which are going to be leveled with a screed. If tiling is planned, the data about it is used.

Options for arranging the floor on the balcony

Some homeowners use the balcony purely for functions that do not involve maintaining a comfortable temperature for a person. Others take measures to insulate and protect the premises from precipitation.

Cold

This is the standard option for an open balcony. You can make the floor cold indoors, but in this case, residents need to visit it in shoes and warm socks so as not to get cold feet. The surface leveled with a screed can be coated with a special polymer-based paint composition. Such mixtures, produced specifically for non-glazed balcony rooms, are not subject to fading under the influence of ultraviolet radiation. Precipitation and other weather factors are not terrible for the coating.

Insulated

If work is being carried out on a glazed balcony, it is recommended to put a layer of insulation. For this purpose, mineral or basalt wool is often used. Linoleum coverings are also produced, equipped with a thermal protective layer and possessing sufficient moisture resistance. They are designed specifically for mounting on a balcony or loggia.

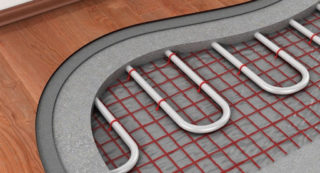

Warm

If you equip the room with heating devices, it can be used as a place of regular stay. However, it is not very rational to put the usual heating devices on a cramped balcony. Therefore, the best option would be to install a floor heating system. At the same time, it is forbidden to install a water structure - there is a possibility of flooding of neighbors. A film infrared product is suitable. It is thin and lightweight, easy to install, compatible with most types of coatings. However, it cannot be used with ceramic veneers. Any underfloor heating should not be installed under a wooden floor due to the risk of fire.

The underfloor heating system is only installed on a well-protected balcony. It is advisable to equip it with high-quality double-glazed windows. Both single and double options are suitable. The floor covering of a glazed and insulated room can be anything. It is possible to use materials that are whimsical, for example, carpet.

Coating options

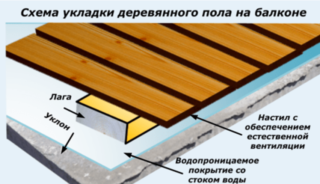

Wood floors

In this case, it is imperative to take care of the glazing so that a large amount of precipitation does not fall on the material. For the finishing layer of the floor, both solid boards and composite wood-polymer products are used. Before making the floor on the loggia, it is also important to stock up on waterproofing material. Plain polyethylene is suitable for boarding. It is laid in two or three layers, and logs are mounted on top. With a slab plane, they are fastened with self-tapping screws. Then they create a lathing frame by mounting wooden beams on the logs. Boards are already laid out on this basis.

Tile

Finishing with ceramic or tile - an option for a closed cold balcony. It should be borne in mind that this option seriously loads the concrete floor. It is worth choosing it if the homeowner is confident in the ability of the slab to withstand all the static and dynamic influences that are planned to be exerted on it during the operation of the room. The packaging of the products usually provides step-by-step instructions for installing them.

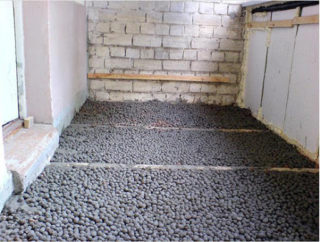

Screed

Its creation is the initial stage in the installation of a number of coatings, including tiling. However, it is also done on a cold open balcony in order to level the surface and eliminate cracks and bumps. The screed is wet and dry. The first method is suitable when the main goal is to eliminate irregularities and cracks, and involves working with a cement-sand composition. But it also has a drawback - an increase in the load on the structure. The dry version involves the use of expanded clay or a ready-made composition for the screed and is used to insulate the balcony. Gypsum fiber sheets are placed on top of the bulk material layer. A topcoat can be mounted on them.

Self-leveling floor

Bulk polymer compositions are good with durability, a wide selection of shades and the ability to spread over the surface in a thin even layer. They are resistant to temperature extremes and have good waterproofing properties. To use them, you need to prepare the screed and prime it many times. The composition is rolled out on a plane so that the layer thickness is at least 2 mm.

Laminate

Laminate is used only in glazed rooms.If insulation is not planned, products of class 33 or 34 are purchased. They are more resistant to water and temperature instability than other types of panels, but they also have a high price. In a warmed room, which has become a continuation of living rooms, you can lay a more whimsical laminate. The material is laid on a substrate made of foil-clad polystyrene foam, which performs the functions of insulation and noise leveling. 2-3 layers of plastic film are laid under it. If the slab is not cracked or severely damaged, it may not be screed. It should be remembered that this material does not tolerate aggressive chemical influences, therefore many cleaning agents are not suitable for it.

It is in principle impractical to wash the floor covered with laminate of 31 and 32 classes. His cleaning comes down to sweeping. Items 33 and 34 are cleaned using mild soap.

Linoleum

The material is used only in well-protected warm rooms. Linoleum does not tolerate subzero temperatures, acquiring fragility in such conditions. If a roll material with a thermal insulation layer is selected, additional insulation is not necessary. Also, linoleum is susceptible to water, this is expressed not only in the loss of a presentable appearance of the surface. When moisture penetrates under the material, it cannot evaporate freely, which leads to dampness and creates favorable conditions for mold and mildew.

General recommendations

Previously, the homeowner needs to calculate how much coverage will be needed to complete the work, and purchase the material in the proper amount. The subfloor is then prepared for installation. Phased plan:

- The old coating (if any) is dismantled, the waterproofing layer used during its installation is removed.

- The base surface is leveled with a screed. The maximum permissible thickness for a wet screed is 2 cm. With a larger value, the base will not be able to withstand such a load. The thickness is checked against the calibrated beacons.

- The surface is degreased and primed. After that, it can be painted. The mixture is applied in several layers.

If you decide to lay tiles, you must prepare a spatula and adhesive. The latter is applied to the screed, and not directly to the product. When the surface is lined, it needs to be cleaned.