The lining is used for sheathing the door leaf outside and inside. Pine or spruce behaves well in rooms where the humidity is low, and the temperature is in the range of -5 - + 30 ° С. Alder, Siberian larch are used for cladding doors from lining with their own hands in a sauna, steam room, attics. Artificial MDF boards are a cheaper version of the natural version, they are used in different conditions.

Characteristics and properties of the lining

Natural material is thin cladding boards, which are produced from whole natural raw materials or use residues from wood processing. The elements are joined using a thorn-groove connection.

Lining MDF is a facing material that belongs to the group of environmentally friendly coatings. Extruded fine chip panels are considered an alternative to natural planks or plastic strips. The adhesive in the mass is legin - a natural component of wood, and phenol and epoxy resins are not used.

The difference between artificial and natural boards:

- have less weight;

- easier to install;

- a wider variety of colors, textures, imitation options not only for wood, but also for stone.

Wooden and synthetic lining is produced in the form of profiles, which differ in locks, cross-sectional shape. The basic profile is the Standard trapezoidal section, in which the edges are cut at 30 °. On the back there are grooves to compensate for changes in the size of the part

There are varieties:

- Calm;

- Europrofile;

- Euro lining;

- American.

The properties of the lining are suitable for door cladding. Resistance to fungus and decay depends on the breed, but all material is treated with antiseptics. Resistance to fire is provided by modifiers in the composition of MDF plates and fire-resistant impregnation of natural wood. All materials are easy to paint, so the door can be designed to suit different interior styles.

Rules for choosing material for the door leaf

Before the start of production, wood is selected and rejected raw materials. The selected round timber is fed to the sawmill, where it is dismantled into individual edged boards, from which the lining is made. The products are manufactured in accordance with GOST 8242-1988, and European standards DIN 68-126-86 are also used. The quality of the material is checked before transferring it for sale, as a result, the product is assigned a grade.

Choose a material for door cladding according to the following characteristics:

- the moisture content of natural wood should not exceed 8 - 12%;

- determine the number of knots and their condition (alive, inanimate, fallen out, staggering), for the living, the color of the color matters;

- find areas of infection by the fungus in the form of blue areas;

- check the compliance of the geometry and dimensional parameters of the board, as well as the degree of curvature;

- reveal wormholes, cracks;

- determine the direction (tangential, radial) along which the cut was made.

Drying is done during production in heating chambers or using an innovative infrared method. The correct geometry of the board is obtained on planing machines, where the product is processed simultaneously from four sides.Here, the lumber receives a groove and a spike from different sides for perfect joining during installation.

Classic material is produced in 1, 2, 3 grades. Elite types Extra, Elite and others are distinguished by the method of manual rejection.

Required elements and materials

Before starting work, mark the surface of the door leaf, for which you need a tape measure, a pencil and a square.

Tool list:

- building level to determine the verticality of elements or horizontality in a complex drawing;

- rubber hammer, pliers;

- electric drill, screwdriver;

- circular saw, jigsaw or hacksaw for wood.

Of the materials, you will need toothed clamps of different sizes for fastening the boards, for example, if the sheathing is mounted on a metal sheet. The elements are fixed to the wood with screws, and they are fixed to the metal with self-tapping screws. It is preferable to take galvanized or stainless steel clamps.

You will need an antiseptic and impregnation for fire resistance. Such processing is done independently before facing, since the material is often sold raw. Only MDF lining is processed, in which modifiers are in the raw material.

If the door is insulated on one or both sides, pieces of insulation will be required. Such material can be polystyrene, extruded polystyrene foam, mineral, stone and glass wool, foam rubber are used. To install the insulating layer, you need a lathing made of a wooden lath with a section of 20 x 40 mm. It is fixed in wood with screws, and self-tapping screws for metal with fine threads are used for the steel surface.

The lath is leveled using wedges or spacers. Elements can be made by yourself or purchased ready-made with a grooved surface in the store.

Making a door from a lining with your own hands

Before installation, the sheathing board should lie for about a day in the room so that the material adapts to the microclimate in terms of humidity and temperature. Lamellas only from the store often burst and crack during installation. For a complex pattern from the lining on the surface of the canvas, you need to make a drawing.

Step-by-step procedure for trimming a door sash made of wood:

- The canvas is removed from the sheds, its surface is cleaned.

- Unscrew the hinges, handles from the sash, remove the locks;

- The lining starts from the side of the castle, so the first segment is measured.

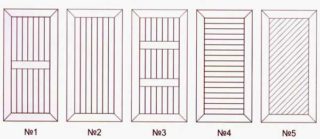

- The lamellas are cut into pieces depending on the selected pattern, sometimes the boards are placed not only vertically and horizontally, but also a patch is used in a combined combination or at an angle.

- The first part is placed along the edge, the position is checked with a level and a square, fixed with finishing nails, such hardware is least noticeable.

- Subsequent elements are joined by a spike in a groove and fixed in a similar way, the ends are sanded.

The finished surface is varnished, and after hardening, the fittings are fixed in place. If you have to sheathe a steel door, the procedure is similar.

Door decoration with clapboard for iron:

- Remove the accessories, clean the surface.

- Before installation, the strips are attached to the surface of the clamps, they are placed on the self-tapping screws using a screwdriver.

- The lamellas are fixed to small holders with screws or self-tapping screws.

When insulating, the insulator is cut into pieces and inserted between the rails. It is glued to the surface of the canvas, since in an upright position the pieces can settle over time.

Door surface treatment tips

After installing the slats, problems arise that can be avoided if you know the intricacies of installation. Sometimes grooves appear between the elements after the boards have dried. During installation, you need to put the lining as tightly as possible, using a rubber mallet for this. Boards are placed with a spike up and a groove down with a horizontal arrangement of lamellas.

Tips for processing a door leaf with clapboard:

- Before installation, they are treated with a special chemical preparation so that mold does not form on the surface of the cladding. The last board is placed near the canopies, so the longitudinal cut of the lamella will be less visible, which is not always smooth.

- The lining is of different widths, which must be taken into account when calculating. It is necessary to measure the length of the canvas and its size in width, count the number of strips so that the material does not remain and it is enough for the sheathing. If the store has to choose lamellas of a different width, recalculate along the way.

- Sometimes the nail heads spoil the overall look of the canvas. To solve the problem, they buy a doboinik in the store - the tool will help to hide the nails. It is undesirable to drive the cap inward by more than 3 mm.

When cutting strips to the desired size, branching fibers spoil the picture, they are difficult to remove with emery. Use a fine-toothed hacksaw, for example, for metal, or place an appropriate file on the jigsaw. The inner skin layer at the joints is coated with PVA. The glue will harden, and when it gets cold, it will not allow condensation in the cracks, and the lining will not deform.

It is possible to sheathe the sash using an ornament from the lining, for this an American woman is more suitable. Such a board can be installed with an overlap and is suitable for unusual decor, for example, diagonally. Old plywood can be used as a backing

Painting the door from the lining

High-quality lining is usually not painted, but covered with a layer of varnish several times. Varnishing shows the texture of the pattern. If the wood is too light, use a stain to show the wood.

Coloring is carried out in such cases:

- exfoliation of the old layer;

- tarnishing of lamellas;

- ingress of fat, oil, coloring matter, the appearance of fungus and mold;

- interior renovation.

Painting is laid, if you want to level the surface, repair chips, fallen knots, large gaps. Use Senezh Neo or Hoarfrost to lighten the darkened areas on the lamellas. Degrease the surface with acetone solvents. Roughness is cleaned with emery.

A putty is used on wood, it is pressed into cracks, places of fallen knots, and after drying it is sanded. Then the putty areas are primed and painted.