Normative documents contain instructions and recommendations for the installation of fillings of openings. If the window is installed in accordance with GOST, then the frame is securely fixed, all protective layers are made. The use of foam as a fastener is not allowed, since the material deteriorates over time. The formed gaps let the street moisture and cold pass through. The ways of fixing the window in the opening are stipulated in the standards and are always followed.

General requirements for installation in accordance with GOST

An expensive luxury window with a multi-chamber glass unit reduces its functionality if it is installed in violation of the rules. The standards were developed by technologists so that after the installation of PVC windows in accordance with GOST, the room has an optimal microclimate. There should be no risk of the frame falling out of the opening.

There is a document that defines the correct installation of windows - GOST 30.971 - 2002. It provides technical conditions for the organization of the assembly seam between the window frame and the end of the walls.

The abutment seam includes:

- an outer layer that insulates from moisture, but allows steam to pass through;

- central - reduces heat losses;

- internal - insulates from household vapors.

The layers combine functions, for example, the outer one additionally protects from the cold, which is taken into account when calculating the indicators of the window frame. The design and composition of the assembly seam are established in the working annexes, which are included in the text of GOST. The installation rules are developed in accordance with building codes and standards, taking into account standard requirements.

- The seams must withstand operational loads, for example, precipitation, heat, frost, wind, and not collapse when the structure shrinks.

- Materials for joints must be resistant to deformations, sedimentary, temperature changes in the size of blocks and wall ends, while taking into account the calculated degree of compression.

- The installation seam has such an indicator of thermal protection that the inner surface of the slope has a temperature not lower than the normative according to SNiP.

- the insulation material cannot have sound insulation properties and water resistance is lower than the corresponding indicators of the window structure.

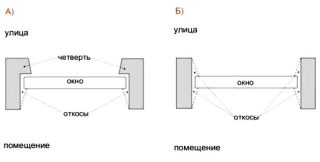

- The seams are made straight, if the end of the opening does not have a quarter, or angular, in the case without a quarter.

According to the norms, it is correct to install the outer protection of the seams in the form of flashing strips, ebb tides, slopes. Inside, the gaps are covered with plaster or panel cladding is made, for example, from drywall or plastic.

Preparatory work

Disassembly of existing window frames for the installation of plastic windows in accordance with GOST is performed carefully or cut into pieces. In the first case, old windows can be used in other buildings.

Dismantling begins with freeing up the workspace:

- removing flower pots from the windowsill;

- remove the curtains;

- the area around the window is covered with construction cellophane.

Prepare an extension cord so that the power tool can reach the outlet.

Dismantling sequence:

- Remove the moving parts of the window.

- In the deaf parts, the glazing beads (longitudinal elements supporting the glass) are removed.

- The window sill is removed so that the integrity of the window opening does not suffer.

- Remove the external ebb.

- Remove the frame by cutting it.

Installation of PVC windows in accordance with GOST assumes that the opening is freed from the main and finishing parts of the old block. The concrete sill slabs are broken in the middle with a hammer, the exposed reinforcement is cut, and the halves are then removed from the side openings. Window sills are removed with a perforator, helping with a hammer if they are made of plastic, wood, MDF, metal.

Ebb tides can be attached to the frame or window sill, they are detached by taking out the hardware. After removing the ebb, the window structure is removed. Work is carried out with a mounting cutter for professionals or use an electric jigsaw, a simple hacksaw for wood. The frame is taken out in parts as it is released. After that, the interfering influx of solution is removed and the old insulation is removed, since it will not be needed.

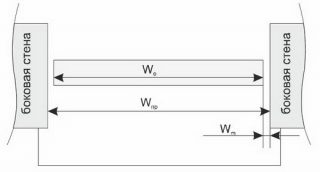

Check the mounting opening in the wall where the window will be installed. It must have the same dimensions horizontally at the top and bottom, and vertically on the right and left. The error is allowed up to 1.5 - 2.0 cm. If the opening is curved, the frame may not enter it. Otherwise, the window block will dangle, there will not be enough anchors or dowels to fix its sidewalls.

Required tools and materials

For dismantling, in addition to a hammer and a jigsaw, you will need a crowbar, a grinder with a circle for metal (for reinforcement). The insulation is taken out with gloved hands; you can use a construction knife and a spatula to separate the glued material from the ends.

The solution is beaten off from the landing site using a perforator with a spatula nozzle. A screwdriver is used to unscrew the screws, screws, nails are removed with a nail puller, and dowels, anchors are sawn with a grinder.

To install PVC window blocks, you will need the following tools:

- hammer drill, drills with victorious tips, screwdriver, drill;

- drills with a diameter of 6 mm are used to mount the window on the mounting plates, and size 10 is taken for drilling under the anchor;

- construction gun for foam;

- knife on g / cardboard, hammer;

- building or laser level, tape measure 5 m, pencil, plumb line;

- metal scissors, pliers, Phillips and flat screwdriver, chisel.

A puncher is needed to make holes in the end of the opening for dowels, anchors. It is better to screw the screws with a screwdriver. In wooden walls, a punch is not needed, a drill and metal drills of different sizes are suitable. To install the window sill and ebb, some of these tools will also be needed.

Materials for mounting a frame with double-glazed windows:

- spacers and mounting wedges made of dense plastic, the quantity is taken so as to install the elements around the perimeter of the window;

- assembly foam based on polyurethane foam with a low expansion rate to fill the space between the frame and the wall;

- a vapor-permeable sealant (PSUL) for organizing self-ventilation and protection against moisture from frozen foam;

- waterproofing tape for installation inside the room based on polyethylene with a thin aluminum layer;

- diffusion tape to protect the assembly seam from precipitation and rays.

Simple or adjustable anchors, self-tapping screws, and dowels are prepared as fasteners. The modern method involves mounting the frame on plates. In addition, you need support brackets, silicone sealant, support profile.

DIY window installation according to GOST

The window frame made of plastic and the end of a concrete or wooden wall have different coefficients of expansion, therefore, the material of the assembly seam is selected so that cracks and cold bridges do not appear during shrinkage or deformation.

This is the problem of single-layer walls, for example, from expanded clay concrete or solid bricks. In this case, the weak area is the wall near the frame due to the high heat conduction. Areas prone to condensation and mold formation. If the ends are without a quarter, heat loss increases.GOST recommends installing boxes with a thickness of at least 13 cm if the quarter-less method is used.

Installation procedure according to GOST standards (with the removal of a double-glazed window):

- select fastening anchors taking into account the strength of the walls;

- remove movable sashes, take out double-glazed windows from the blind parts of the window;

- in the walls and a quarter before installation, the PSUL tape is attached;

- the frame is set horizontally and vertically;

- the frame profile is drilled through and fixed to the end of the opening with a metal anchor;

- install spacer wedges, foaming gaps;

- hang the sashes and put blind double-glazed windows;

- cut off the foam after hardening.

According to the standards, the anchors are placed every 50 - 70 cm, the anchor is buried in concrete by 4 cm, stone and light concrete are drilled by 6 cm. Fixation starts from the bottom of the frame. The anchors are not immediately tightened, but the correct installation of the block is checked, after which the fasteners are squeezed all the way. If this causes a skew, the anchor is released, the frame is leveled and the steps are repeated.

Installation without removing the sashes and double-glazed windows is performed on special plates, which are simultaneously attached to the side of the frame and fixed to the end of the wall. This method allows you not to drill the box, you can freely adjust the installation level. But the plates are not suitable for large windows.

Windows can be opened immediately after installation. For large sashes, there is a limitation - you need to wait 24 hours after installation, only then bring the glass sheets open.

Installation of plastic slopes and accessories on windows

PVC slopes are mounted on the day the windows are installed in block and panel buildings, in brick buildings they are installed on the second day.

Use options:

- sandwich panels;

- plastic slopes with removable platbands.

The first view can be set so that you get slopes at dawn (at an oblique angle to the plane of the window). So GOST recommends to increase the flow of light into the room.

The second type is set if you need to trim the walls, but the slopes are already there. The edges of wallpaper or other wall material are neatly brought under the platband. If the room is being repaired simultaneously with the installation of windows, the sandwich panels are mounted after the repair is completed.

The accessories category includes elements:

- a stepped ventilator;

- mosquito net;

- retainer;

- droppers;

- blinds, other devices to improve work.

The window sill is placed after the frame is installed, but before the slopes are made. If there is already a side finish, grooves are made in it with a depth of 1 - 6 cm, where the ends of the window sill board will enter. The assembly seam is made with foam. The interval from 8 cm is foamed several times, at intervals of 7 - 8 minutes.

During the installation of the slopes and the window sill, the glass on the sashes is covered with cardboard or foil.

Self-tapping screws are driven into a substitute profile at a distance of 1.8 - 2.0 cm from the bottom of the edge. Large gaps are pre-sealed with a layer of plaster. When adjusting the size of the window sill, the tolerance for free movement in heat or frost is taken into account, the panel is made shorter by 1 cm.

Support elements are placed under the window sill every 50 cm, they are fixed against shear with self-tapping screws. The board is placed, the level is controlled so that there is a slight slope of 2 - 4 cm towards the room, depending on the width of the panel.

Application of PSUL and vapor barrier tapes

The use of PSUL tape allows you to start forming the assembly seam even before installing the window. It is attached to a self-adhesive base along the perimeter of the opening. This creates protection against external moisture, and after such treatment, the foam is not squeezed out of the frame contours. SNiPs regulate the production technology for the release of products for the device of ventilated gaps when installing PVC windows.

Ribbon properties:

- resistance to ultraviolet rays;

- tolerates heat and cold in the range of -45 - + 85 ° С;

- inert reaction to chemical irritants in the air, fats;

- does not lose elasticity during operation;

- repels moisture;

- fungus, moss, mold do not grow on the surface;

- passes steam of the order of 0.15 mg / (m · m · Pa).

A tape is produced from cellular polyurethane foam, which is impregnated and covered with a special composition. An adhesive layer is applied on one side. The tape comes on sale in rolls, which are unwound before installation so that the material does not lose its properties. After removing the film from the surface, the impregnation reacts with oxygen and the product increases in size. Use tape across the width of the side of the box.

The surface of the slope is cleaned of dust for better adhesion, and the porous materials are additionally primed. The expansion process is influenced by temperature. At room temperature, the tape expands in half an hour, and in the cold, the process continues for two days. After that, the installation gap with the installed tape is blown out with foam.