Egg production in winter depends on house temperature, lighting and ventilation. Laying hen owners are trying to build an all-season hen house with their own hands for 20 chickens in order to bring the conditions of detention closer to ideal. The materials of the enclosing structures are chosen so as to achieve the standard indicators and not spend extra money on the construction.

- Choosing a place on the site

- Types of chicken coops for 20 chickens

- Condition requirement

- Design and dimensions

- Required tools and materials

- Overview of wall materials

- Chicken coop foundation type

- Making a chicken coop with your own hands

- Foundation

- Floor

- Walls

- Roof and ceiling

- Windows and doors

- Ventilation

- Additional lighting

- Poultry house arrangement

- Winter conditions and walking

- Possible construction errors

Choosing a place on the site

The poultry house is built in a dry, elevated place in the country, low areas are not suitable, because due to humidity, the pets become lethargic, cough, and reduce activity.

SNiP 30.02 - 1997 regulates the norms for placing the poultry house:

- from the fence or adjacent border - from 4 m;

- from your own or neighboring housing - from 12 m;

- from a reservoir, a well, a well - 20 m.

The chicken coop is protected from the wind by a wall of a barn, a garage, trees and bushes, there should be a place for building a walking area nearby. Place in areas protected from the sun so that the heat does not cause dehydration.

Types of chicken coops for 20 chickens

Depending on the functionality, the buildings are made capital or rearranged if necessary, choosing a new place with dense grass. Each variety has its own advantages and disadvantages.

Characteristics of different models:

- Portable. For the rearrangement, the strength of two people is required, since the structure weighs a lot. There is an option to equip the house with a frame with wheels, then it is transported. This design will greatly facilitate transportation. The frame is made of bars or profiled pipes. A mobile aviary is made for a portable poultry house.

- Stationary. They are built for a long time, the building is placed on the foundation. The walls are made of large or small blocks, made of wood. Frame construction is sometimes used. The buildings are solid, thoroughly insulated, there is usually a walk with lattice walls nearby.

Multi-tiered floors are placed one above the other to conveniently serve the livestock. In such a poultry house there is no crowding of chickens in a small area. The front walls are usually sewn up with a fine-mesh steel mesh, and the partitions are made along a frame of bars.

Condition requirement

A bird shed should provide warmth in winter and cool in summer. Drafts that are dangerous to the health of adult birds and chickens are not allowed inside. In summer, ventilation is needed so that the temperature does not exceed + 25 ° C.

For internal arrangement, the following indicators are taken into account:

- Humidity. Dampness negatively affects the development of offspring. I provide ventilation in the hen house, for this they put a ventilation system, provide for opening openings.

- Lighting. In winter, they put lamps, and in summer, sunlight is enough.

- Peace. Chickens may be intimidated by loud road noise and barking dogs. This is taken into account when positioning.

To protect against predators and rodents, a mesh is provided in the finishing layer of the base and bottom of the walls. Such individuals carry infections that are dangerous to chickens, especially chickens and young animals.Additionally, traps and rat traps are installed.

Design and dimensions

Dimensions are planned taking into account the number of birds. The norms regulate the content of two to four chickens per 1 m². Sedentary broilers are housed in a similar area in smaller numbers.

Room dimensions:

- chicken coop for 20 chickens with broilers - area 5 - 7 m²:

- poultry house with meat breeds - 8 - 10 m².

The summer house for birds is represented by a lightweight construction, which gives a roof over your head and protection from the sun. At this time, young animals are raised, eggs are collected, and in late autumn the bird is sent for slaughter. Non-stationary pens are suitable for owners who do not leave birds in the winter. Often, these options are made displaceable to provide chickens with green food.

The winter house is equipped inside and outside so that the laying hens do not reduce the number of eggs. The building has heating appliances, additional lighting, warm nests for incubating chickens. The walls, roof and bottom of the building are insulated, they pay attention to the isolation of doors and windows from the cold. In the entrance openings, vestibules, elastic gaskets are provided.

Required tools and materials

For the construction of a wooden version, planed boards with a thickness of 15 mm and bars of 50 x 50 mm are used.

Tools for the job:

- hammer, hacksaw for wood;

- tape measure, square, level, plumb;

- screwdriver, plane.

Sew up the gaps with OSB plywood. Old frames and doors are used for windows.

Overview of wall materials

Choose categories that do not emit harmful substances when heated. Materials must resist winter and summer temperature changes without degradation.

The following types are used:

- OSB boards. Multilayer particle boards are impregnated with resin, wax, so the products do not absorb water. This material is suitable for the walls and floor of the poultry house, since it does not require regular treatment to increase the resistance to moisture. Outside, it is painted with oil, acrylic and latex compounds of different colors.

- Building blocks. Aerated concrete, foam concrete, cinder blocks retain internal heat well. Erection from such materials takes a longer period of time, is a laborious process. Gas blocks, unlike foam blocks, absorb water, so the surfaces are waterproofed. Building blocks are classified as non-toxic.

- Brick. The durable material is environmentally friendly. The walls of such a chicken coop have an attractive appearance. Red brick does not absorb water, while silicate brick requires protection from moisture. The most time consuming type of building for chickens. The heat capacity is average, so the winter chicken coop for 20 chickens is isolated from the cold.

- Wood. The most suitable material in terms of practicality and labor intensity. Environmentally friendly wood creates an acceptable microclimate inside the house. The disadvantage is that the material deteriorates from moisture, rots. Wood is destroyed by microorganisms, therefore, before assembly, the elements are treated with antiseptics, fire retardants from fire.

Coquina is used. The stones are of medium size and keep warm well. The outer surface is trimmed to improve the appearance, if this is important for creating a courtyard landscape. You can put it not only on a cement-sand mortar, but also on a clay mixture.

Chicken coop foundation type

The base is not suitable for all house models. Wooden buildings, summer frame options from a professional pipe do not require a foundation. When installing, they put bricks, pieces of wooden lumber of a suitable section.

Columnar foundations are most often used for wooden buildings on a frame - such chicken coops are almost always lightweight.

For supports take:

- prefabricated reinforced concrete elements;

- concrete monolithic structures are poured;

- pillars of ceramic bricks are laid out.

A pile foundation is installed if a stationary chicken coop is built from bricks, blocks on heaving or swampy soils. Piles are distributed along the perimeter of the walls, holes in the ground are made with a garden drill. A homemade device is prepared for twisting. Individual elements are connected with a metal grillage.

The strip foundation is built under heavy buildings made of bricks, cinder blocks. A trench is dug along the perimeter of the walls, crushed stone is added at the bottom, roofing material is laid as waterproofing. Reinforcement is placed in the formwork before concreting. The depth of the laying is made 50 - 70 cm, before drawing up the project, the type of soil is determined.

Making a chicken coop with your own hands

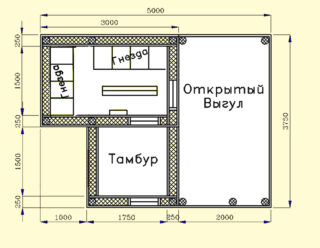

Before building a wooden poultry house, a detailed drawing and plan are made. The layout of the walls, partitions, the location of the perch, walls is indicated. They draw on the layout of the chicken coop with a vestibule, a walking area, make vertical cuts to show the elements of joining the nodes.

Foundation

For a wooden structure with winter insulation, a columnar foundation is suitable. They dig holes in size so as not to make formwork, but to pour concrete directly into the ground. A layer of sand and crushed stone (10 and 15 cm) is poured at the bottom, roofing material is laid so that the ends can be brought to the wall, and the edges protruded above the ground. Concrete vibrates during pouring.

Floor

Wooden logs are fixed to the lower strapping belt, then a rough flooring is placed, roofing material, insulation, vapor barrier are placed on it.

For the top flooring, apply:

- planks;

- clay.

Sometimes the floor is made of concrete, but then you need to provide a thick bedding of straw and hay.

Walls

Racks made of timber are attached to the lower beams with self-tapping screws, additionally fixed with steel corners. A similar upper harness belt is made from above for stability. Vertical posts are connected with transverse beams, angular and diagonal braces are used. Sewing plywood is connected on a bar, no seams are made in the air.

Roof and ceiling

The roof of the hen house is single-pitched, gable. The first option is preferable, since such a roof can be easily made removable to facilitate maintenance of the internal space. If the slopes are steep, then an empty area appears under them, which increases heat loss. In this case, a false ceiling is made, which is hemmed with plywood with the installation of an insulating layer.

Windows and doors

Heat is transferred through the openings, but such elements provide natural light. Install 2 to 3 glasses to reduce losses. Inside, the windows are covered with an iron mesh with fine meshes for safety. For the winter, plastic wrap is stuffed outside.

Ventilation

The ventilation device inside the chicken coop for 20 chickens is made of plastic or asbestos-cement pipes.

The diagram consists of details:

- an inlet with a pipe at a level of 25 - 30 cm from the floor surface inside;

- an outlet manifold under the ceiling that leads the exhaust air to the roof.

Pipes are placed in opposite corners on a diagonal to increase the speed of movement of streams.

Additional lighting

Chickens lay eggs effectively in winter if the lighting is on for 12-13 hours daily. The sun sets early in the cold season, so lamps are installed. They are placed at a height, and provide an automatic on and off mode. If there is a lot of light and for a long time, then egg production will decrease, as the chickens will be anxious and irritated.

Poultry house arrangement

Pet supplies are also important, along with microclimate and heat retention. Chickens are launched into the poultry house after being fully equipped with drinkers, feeders. For convenience, perches and nests are made for them.

Varieties of elements of the internal arrangement:

- Perches.They are prepared from a wooden block with a cross section of 30 x 40 or 30 x 30 mm. The sharp edges are smoothed, I cut with a plane so that the pets are comfortable to hold on. Containers for collecting manure are installed under the perches. The distance between the chickens is 30 cm per head.

- Nests. They are open and closed, the second option is preferable. They are more difficult to build, so many owners get by with open models. The size of the nest for meat birds is 30 x 40 cm, for broilers it is increased. For 20 chickens in the poultry house, ten warm nests are enough, which are lined with straw and sawdust inside.

- Drinking bowls and feeders. It is better to do it from wood in order to exclude the entry of harmful substances into the body of pets from plastic or PVC varieties. Install devices so that a person can pour food, pour water, without going inside the poultry house. The stores sell ready-made automatic feeders and drinkers that are easy to use.

Chickens require thick bedding on the floor. Use dry waste woodworking industry, put chopped hay, straw. Sometimes dry foliage of trees is poured. Dry moss, sphagnum peat are well suited. You can mix these materials in different combinations.

Winter conditions and walking

In the cold, they put fan heaters and infrared lamps inside to raise the temperature. Electrical appliances are expensive to use, so they use stoves, gas convectors, water heating, if possible.

In winter, chickens are driven out into the open air if the temperature does not exceed -12 ° C, and the weather is calm. For this, a mesh fencing with a roof is provided; the entrance to the aviary comes from the chicken coop. Sawdust and straw are laid on the floor of the walk.

Possible construction errors

The chicken coop is placed directly on the ground, but you need to make the floor, frame it with a net from martens, minks and raccoons. Raise the house about 10 cm from the ground.

To access the collection of eggs from the nests, they do not make a separate entrance; such meta are located in the back of the chicken coop. It is necessary to provide for a separate door for this so that the chickens do not consider everyday entry as an encroachment on their territory.

They put a bucket instead of a drinker. Chickens jump to the edge when water becomes scarce, the container overturns, the pets drink from a puddle on the floor. You need to put a special drinker.