Thanks to the development of technologies and the invention of new covering materials, modern private construction is able to carry out the most complex projects for the construction of residential buildings. Pitched roof houses remain a priority for most property owners. In almost all cases, developers have to deal with shrinkage of wooden buildings. This leads to the need to use such a frame element that would compensate for its deformation. Sliding support for rafters - a beam fixed to a support bar with a movable connection on a Mauerlat. Thanks to such details, it is possible to assemble a balanced and durable frame that meets all building codes.

Functions and characteristics of the sliding support for the rafters

Sliding rafters are used in the construction of solid wood houses. Structures of this type, after erection, shrink up to 15% of their original parameters. Changes occur unevenly, depending on the factors that affect certain structures.

The movable connection of the rafters and the Mauerlat allows you to completely neutralize the curvature of the frame, prolongs the turnaround time, which apply to rigid roof frames.

Purpose of the product:

- elimination of the expansion of the bearing walls when they dry out and decrease in size;

- prevention of deformation of the frame with increased internal pressure;

- preservation of the shape of the roof, regardless of the processes occurring with wood.

The floating connection of rafters has shown its effectiveness in hundreds of buildings erected on the basis of this method. Regardless of changes in the parameters of the building, its roof retains its shape, strength and stability.

The main advantages of this technology:

- creating an additional margin of safety for the frame;

- ease of installation, for which there is no need to purchase expensive tools or have solid work experience;

- reducing the share of heavy manual labor associated with balancing the frame and creating cuts;

- there is no need to install filly on the roof, since the rafters protrude a sufficient distance from the walls;

- the ability to freely change the size of the beams with temperature and humidity changes.

The correct choice of material and adherence to the technology of installing movable fasteners for rafters guarantees a high-quality end result. At any degree of shrinkage, the structure will maintain precise geometric shapes.

Application area

The strongest shrinkage of timber structures is observed in the first 2-3 years after their construction. Changes in dimensions occur under the influence of factors such as pressure and fluctuations in the moisture level of the wall material. The height of each element individually and of the entire structure is reduced. The end walls on which the ridge stands are subjected to a greater load, since heavy rafter legs are attached to it, sometimes reinforced with struts and crossbars. All this leads to uneven deformation of the building at the initial stage of operation.Floating fasteners for the rafter system allows you to painlessly solve this problem.

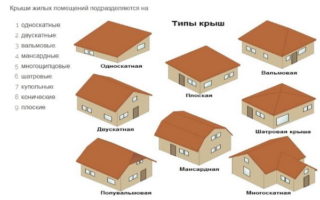

The systems have found application in structures of this type:

- single-slope;

- gable;

- hipped;

- hip;

- tambourines.

The massive fillets on the roof serve to balance the vertical pressure of the rafter system, reinforcing it with their weight on the side walls.

Mounting methods and technology for the device of the rafter system

When planning the construction of a house, it should be borne in mind that the free movement of each beam can be 5-15 cm, depending on the size of the building. In addition, the mounting method is determined by the selected type of rafter system.

Based on the features of the building project, the following fasteners are used:

- Floating. It is used when the length of the beam is maximum and the changes in size exceed the technical capabilities of the lock connection. It is used in hanging systems, where the main load falls on the ridge and supports. A cut is made in the Mauerlat, into which a metal strip is installed, which eliminates friction. The filly in the rafter system is installed to increase the width of the overhang to the desired parameters.

- Sliding. It is used in the construction of small buildings with a potentially low percentage of shrinkage of the roof frame and walls. The Mauerlat and the beam are connected with a lock (ruler and bracket), the knot simultaneously provides a reliable connection and free sliding of the inclined element. The filly rafters are made with a sufficient margin of safety from a bar with a section of 100x200 mm.

Thanks to the use of such systems, the rafter legs adapt to the size and geometry of the building, compensating for the bursting loads to which the load-bearing walls are subjected.

Varieties of sliding type supports

The use of movable fasteners of the roof frame is the only method that prevents it from deforming during the shrinkage period of the building. You can attach the rafters both to the Mauerlat and to the ceiling, if it is made of massive timber. The clips themselves have a fairly simple device and quite affordable cost. The locks consist of a guide strip and a corner with a loop.

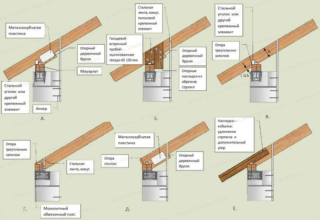

During construction, connections of this type are used:

- Open. They are collapsible products, which include a guide fixed on the rafter leg and a metal corner fixed on the Mauerlat or ceiling plate. The number of holes for hardware varies from 1-5, and the free wheeling reserve is 60-150 mm. The mount is robust and functional. With proper installation, the bar will easily slide over the Mauerlat, which completely eliminates the possibility of deformation of the frame.

- Closed. The product is non-separable, it is sold immediately in a condition ready for installation. A corner with a loop is attached to the support bar, and a guide bar screwed to the rafter is threaded into it during installation. After fixing the rafters in the frame, adjusting the position of the lock becomes impossible. Therefore, when choosing such parts, you need to carefully approach the calculations and observe accuracy during installation.

Open type fasteners are more practical and reliable in operation. Their design allows you to correct mistakes made during installation by an inexperienced technician.

Fastening the rafter legs to the Mauerlat

To securely fasten the rafter leg to the Mauerlat, two locks are used, installed on both sides of the beam. This technique eliminates the possibility of curvature of the beam in the process of changes in humidity and temperature. The rafter must be fastened so that the maximum distance of its free travel is ensured.

You can limit yourself to one fastener when building a roof with a gentle slope or a small size, where the likelihood of wood bending is minimal.When using a floating type of connection, the support bar is grinded to a depth of no more than half of its section.

Particular attention should be paid to the quality of the sliding bearings. After installation, the products will be exposed to significant mechanical stress and high humidity. You need to take the most expensive and high quality parts made of zinc-coated alloy steel. It is even better to dwell on stainless steel, since the roof is being made for decades. Initially, the likelihood of rust should be excluded, since it has an extremely negative effect on the wood.

The wooden fragments themselves must be treated twice with an antiseptic and impregnation before construction. During operation, this procedure should be carried out annually after the frame is completely dry.

Features of mounting a sliding support for rafters

The process of constructing a sliding-type rafter system practically does not differ from the technology for erecting a standard frame. The dimensions and angles of inclination of the fragments of the structure must be observed especially precisely.

The following installation features must be taken into account:

- Installing the Mauerlat. If the load-bearing walls are thick enough, this step is skipped.

- Construction must be carried out on a surface of precise geometric shape. For this, a preliminary measurement of the perimeter is carried out and its correction if violations are detected.

- All the same frame parts are made according to the template. This will avoid inaccuracies associated with errors in individual measurements.

- For fastening paired locks, it is advisable to use through studs, tightened with bolts. The axial connection is stronger and more reliable than self-tapping screws.

- When building up, drilling is allowed no closer than 50 mm from the edge of the board, otherwise it may crack.

- When using self-tapping screws on both sides of the extension cord, they must be screwed in staggered.

When installing the rafters, the fasteners should be brought out to the extreme position in order to provide them with the maximum possible movement during the shrinkage of the building.