In the general case, gates are wide gates that close the passage behind the fence or inside any structure, for example, a garage. When choosing the type of gate for a garage or a country house, you need to keep in mind that the main criteria in this case are their strength and reliability. It is equally important that the entrance is functional and does not interfere with what is on the local area or outside it.

Gate types

For self-production, two types of wing gates are best suited: swing and sliding. Each of them has its own advantages and disadvantages, however, when choosing a design, it is important to evaluate the possibility of welding the gate with your own hands.

When choosing the type of entrance alignment, you need to take into account a large number of a wide variety of factors, for example:

- the location of the site relative to the adjacent territories;

- the presence and type of road transport that can enter the site;

- the configuration and design of the already installed fence;

- the degree of necessary protection of the territory.

Both swing and sliding gates have their own design and operational features, so it is important to decide which of them will be the most optimal in each particular case.

Swing gates

Swing structures are considered the cheapest and easiest to manufacture. Moreover, they are characterized by high reliability and unpretentious operation.

Swing gates are also not free from disadvantages:

- take up a lot of space when opening and closing;

- the sashes should hang on hinges, which must be regularly lubricated with thick machine grease;

- the position of the gate wings must be fixed, otherwise, with a strong gust of wind, they may spontaneously close or open;

- on the way of movement of the shutters, it is necessary to remove snow (in winter) and objects that interfere with their work.

The work of swing structures is difficult to automate.

Sliding gates

Sliding gates take up little space, but they require a parallel fence of a certain length for operation. In this regard, they are most often used as entry points.

Structurally, sliding gates are more complicated than swing gates, so it will take more time to make them. You will need special knowledge and a number of original devices.

Making swing gates with your own hands

The most budgetary and also widespread type of gate are swing gates. You can make them yourself without much effort.

The swing type construction in general includes:

- sash;

- frame (if necessary);

- sash cladding material;

- loops;

- locks and latches.

The design will be incomplete if you do not include the pillars, which by and large are not gates, but serve as supports for hanging the leaves.

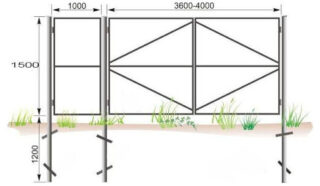

Before proceeding with the manufacture, a drawing is developed, which will indicate the dimensions of all component parts of the product.

- opening dimensions;

- section of supports and their number;

- the depth of digging in the pillars;

- all sizes of frame elements;

- ground clearance, which, depending on the condition of the road, can be from 5 to 30 cm.

Also on the drawing indicate the places intended for the installation of hinges, a lock and a bolt.

The construction of swing gates is carried out in the following order:

- Installation of posts for hanging sashes.

- Preparatory work.

- Welding gate.

- Hanging sashes.

You will need to weld the hinges, mount the bolts, decorate the gates, and then equip them with padlocks, overhead or mortise locks.

Tool

Cook the gate using:

welding machine;

- roulette;

- pencil;

- building level;

- grinder.

A screwdriver, metal scissors and a set of plumbing tools will also not be superfluous.

Installation of poles for hanging.

The posts for hanging the sash are installed in the pits drilled with a garden or motor-drill. Their depth should be at least one meter and at the same time exceed the amount of soil freezing. When pipes with a cross section of 100x100 mm are used as support pillars, the diameter of each pit must be at least 200 mm.

At the bottom of the pit, a sand-crushed stone pillow with a height of at least 15 cm is arranged. Then a pipe is lowered into the pit and the free space of the pit is poured with concrete to ground level. In this case, it is necessary to constantly monitor the verticality of the pillars. For this, a building level is used.

The concreted pillars must stand until completely solidified for at least a week. In this case, the concrete must be periodically moistened with water, which will avoid the appearance of cracks on its surface.

While the concrete hardens, you can start making the sashes.

Sash manufacturing

Most often, a steel equal-flange corner with shelf dimensions of 50x50 mm (main frame) and 25x25 mm (stiffeners) is used.

The workpieces are cut according to the dimensions indicated in the drawing, taking into account the thickness of the supports and a gap of 5 mm between the flaps. Then, having cleaned the corners from rust and dirt, the workpieces are laid out on a flat surface, while aligning all the corners of the future flaps at 90 °. Next, check the equality of the diagonals, cutting the workpieces if necessary. After all the diagonals are exposed and all right angles are joined, the frame frames of the sashes are first baited, the equality of the diagonals is checked again, and only then they are finally welded.

The welded seams are cleaned, the entire frame is degreased and painted.

Hanging sashes

In order for the gate to open without distortions and jamming, you need to choose hinges on a ball or bearing. In order not to be mistaken, the hinges are first welded onto metal plates, and then these plates are welded in place to the support posts and frame frames of the sash.

After the hinges are installed and the sashes are hung, they begin to install the bolt. Typically vertical metal pins are used. This design is reliable in operation and easy to implement.

The choice of locks and external cladding (filling) of the frames entirely depends on the preferences of the owner.

Additional Information

Corner gates, despite their apparent simplicity, can be made in different ways. The presence of a stationary outer frame will significantly strengthen the structure, however, there will be restrictions on height - tall cars or special equipment will not be able to drive through the gate. In this case, more metal will be needed in the manufacture.

When making a frame of a stationary type, you can equip the latter with a removable strip, which is screwed with self-tapping screws to the bottom of the structure. In winter, with a large thickness of snow cover, this bar is dismantled and installed back in spring.

There is an option when the frame is welded and hung on the hinges entirely and only then sawn into two parts.