The iron frame at the base of the structure will help build reliable and durable housing. Houses from a metal frame were previously built for production purposes, they housed shops, warehouses due to the high thermal conductivity of steels. Modern frame structures based on an iron frame compete with wood buildings, since they produce various types of thermal profiles and insulation. Houses are erected in high-tech, modern style, or use the classical genre.

What is a metal frame house

More than half of the housing stock in Canada, USA, Europe, Scandinavian countries, Finland is represented by frame houses made of metal profiles.

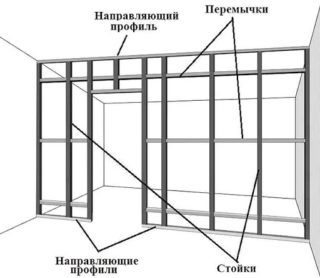

In the structure of the building:

- rows of uprights;

- horizontal runs;

- struts;

- rafter system;

- fasteners;

- thermal insulation filling.

The frame consists of galvanized profiles of various shapes and sections. They are made in a heat-resistant version and prevent the appearance of cold bridges, as well as the appearance of condensation drops. Lightweight steel construction technology ensures reliability and quality of construction. Stiffeners are installed inside the profiles for strength.

The zinc coating protects against aggressive weather conditions, therefore corrosion is excluded. The steel frame does not crack over time, is not afraid of pests, and is safe in terms of fire.

External finishing is performed with plaster, facing brick, siding, plastic. The roof is covered with metal tiles, corrugated board, galvanized steel.

Features of metal frame houses

There are no restrictions for the planning of such buildings, but it is no longer possible to remake a built house from steel structures. The peculiarity is that the entire system of the building frame consists of iron structures, the thickness of the walls of which and the parameters of the section depend on the loads.

The house includes several layers, which have different purposes and functions:

- the bearing layer is represented by steel slats, which take on loads and evenly transfer them to the foundation;

- internal - placed to facilitate installation of 9.5 mm g / cardboard (thickness) to provide a base for cladding;

- front - intended for external cladding and creates a spatial hinged frame;

- insulating - represented by insulating panels made of organic or inorganic materials.

The cost of a house made of a metal frame includes the price of design surveys, building materials, work performed, the cost of cars, energy resources. When buying a typical house for assembly, the cost will decrease due to the exclusion of individual design. As a result, the price for a metal-frame house is at the level of a building with a wooden frame.

Advantages and disadvantages of buildings

The progressive technology of lightweight steel frame structures has many positive aspects that make it popular. The first of them is the speed of production of work on the installation of structures from the foundation to the roof due to the low labor intensity of individual assembly processes.Typical profiles have standard joints, therefore they are connected using the template method.

Other advantages are noted:

- modern exterior of the building;

- a small team of assemblers;

- ease of interior and exterior decoration due to thoughtful details of the frame;

- no shrinkage, no need for a massive foundation;

- an economical house is easy to heat;

- rigidity and strength of the structure;

- long service life (about 100 years).

Steel houses can be refurbished easily and cost-effectively. The frame can withstand seismic activity up to 9 points. Construction work is carried out at different times of the year.

The disadvantages include the fact that the house is assembled by professionals, or the work is carried out under their control. Assembly errors reduce quality and lead to premature failure.

Types of steel profiles

Structural lightweight metal is used for production, from which thin-walled profiles are made. The material is protected from corrosion with a zinc layer.

The method is used:

- hot-dip galvanized;

- cold processing.

In the hot method, steel is immersed in liquid zinc, and the process takes place at + 460 ° C. Zinc reacts with the surface of the iron, and a durable layer is obtained with a thickness of up to 120 microns. Protection withstands mechanical forces, resists acids, alkalis contained in the atmosphere.

In the cold method, the steel is coated with zinc-based agents. Distinguish between the galvanic application process and the treatment with primer, which contains zinc.

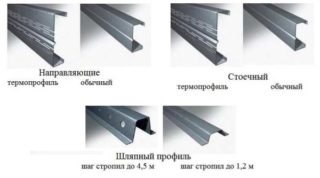

The following types of profile rolled products are used:

- guides;

- hat;

- rackmount.

Beams and girders are used to overlap the ceiling and floor, as well as to assemble the rafter structure of a metal frame for a house. The frame parts are connected using self-tapping screws, rivets, bolts. The resistance welding method is sometimes used. More common are profiles in the form of Z, C, U-shaped sections.

In addition to thin-walled rolled metal, connecting parts, battens, and other structural elements are used. Thermoprofile belongs to the category of energy-saving building materials.

Guides

Simple ones use in installation:

- guide elements for slabs of internal and external walls;

- additional elements in the beam covering system;

- nodes in the frame structure;

- lintels under the windows;

- mountings for wall posts;

- stripes for the C-profile.

Thermoprofile elements are used as a load-bearing frame for internal partitions, ceilings and walls, as well as in load-bearing systems of pitched roofs and hangars. They are installed in the construction of a metal-frame house of low and high number of storeys. Insulated profiles are used in the outer layer of the framework of buildings, they strengthen the weak points of the roof (near pipes, ventilation duct outlets).

Rack

The range includes a C-beam of high rigidity, designed for vertical positioning. They are used to install bearing supports and struts in a frame of various configurations. The links perceive the main longitudinal vertical forces, therefore, they are subject to maximum requirements in terms of bearing characteristics.

Simple profiles without insulation layers are used in the following cases:

- installation of racks in the line of internal and external walls;

- as columns;

- in the form of the main links in the system of girder floors and rafter structures;

- to create braces and belts of trusses and rafter systems;

- in the form of wall beams and girders;

- to reinforce roof girders in the form of prefabricated structures.

The rack-mount thermal profile has perforated inserts and is used to install vertical components of a metal house (rafters, racks, cover girders and truss trusses).

Hat

Such components of the metal frame system are used in the form of an analogue of a standard timber batten. The product has a characteristic cross-section and is produced from thin steel sheets in one-piece cast method with perforated holes. Protect products from corrosion by powder painting and galvanized galvanizing.

Hat varieties are classified according to properties that are indicated in the accompanying documents:

- the width of the plane;

- the height of the side part;

- type of staining;

- length.

Products are produced with a length of 0.5 - 12 m, while the wall thickness is 0.5 - 2.0 mm, and the height of the shelf varies within 20 - 61 mm. Moldings are used for mounting the battens with a rafter leg pitch of 0.6 - 4.5 mm. The counter-lattice device is often abandoned, since perforation on the surface facilitates ventilation, and there is no need for a ventilated gap.

The material does not collapse from condensation, withstands light and heavy roofing, while the height of the slats is important.

Instructions for building a house from a metal profile with your own hands

It is very difficult to build a metal-frame structure on your own without experience and special knowledge. The instruction is intended for people who have skills in assembling such structures or will work in a team with experienced workers.

Thin-walled materials in the form of a house support require a secure fixation of all steel profiles. Stiffening ribs are intended for fastening the skin. Windows and door frames will be mounted to the racks and crossbars, so these links should be as strong and stable as possible.

Stages of building construction:

- foundation device;

- frame assembly and installation of roof elements;

- insulation of vertical and horizontal fences.

After finishing the installation of the frame, the facade, pediment and side walls are sheathed. In the insulation system, waterproofing is used so that the protective material does not get wet.

Foundation device

Use a shallow base type. They choose a columnar version, make a monolithic tape of concrete, or use piles. For the strip foundation, a rigid horizontal frame is performed, which makes it possible to redistribute efforts in weak and unstable soils.

The columnar foundation is made together with a beam frame, while its elements are rigidly connected using special supporting parts. The pillars are made of reinforced concrete, bricks (silicate), prefabricated monolithic products are used. On the piles, a grillage is made using load-bearing metal girders.

The foundation is chosen after studying the qualities of the soil in the field of construction. The depth of freezing of the earth and the level of rise of the soil liquid are taken into account. For non-standard structures, loads are collected to find out the total value that acts on the foundation.

In typical projects, calculations are already there, but for a non-standard layout, you need to order an individual project so that the base can withstand the weight of the house along with the roof.

Frame assembly and roof device

The stiffness of the skeleton is created if the spatial geometry is observed. When setting racks, struts and other vertical elements, a plumb line or a laser level is used to control. The marking of the installation sites is carried out with a level keeping right angles and height marks. The horizontalness of the cross members is controlled by the building or water level.

Work order:

- external fences are made with perforated racks, internal ones are lined with plasterboard, if the requirements for the fire resistance of the structure allow;

- ceiling heights can be arranged up to 4.0 m;

- floors between floors are made with profiled flooring on galvanized beams, they are additionally soundproofed and insulated;

- if the span is more than 4.8 meters, then the trusses are designed to overlap such a gap;

- on the rafter links of the trusses, the crate is made with a hat profile.

Between the double pillars of the outer wall, lay a foam tape backing so that cold does not enter through the gap.

Insulation of a frame-metal house

Protective materials are placed in external fences within the boundaries of the section height of the skeleton links, covered with films on both sides. The external cladding is made in the form of a ventilated facade, polystyrene foam or mineral wool is placed.

The order of work for insulation:

- All cavities inside metal racks, girders, struts are sealed with foam.

- Inside, the wall area is covered with a vapor barrier film, and dense cellophane is fixed on the outside for wind protection.

- For the installation of mineral wool, a partition is needed, more often g / cardboard is used.

- The gap between the panels is laid with insulation, the cut pieces are attached to the hardware protrusions, punching the material with them, pressing the cotton wool against the wall.

The sprayed insulation is durable, allows you to make insulation inside and out. After application, the volume increases and all cracks are closed. The high spraying speed reduces the insulation period, for work they use an installation that feeds the mixture under pressure. The operator's task is to make a uniform layer and cover the entire area without gaps.