Support posts made of wood are used for fences made of corrugated board, picket fence, metal tiles. Wooden fence posts are made of dry material without defects. High-quality supports are not cheap, and the service life of the processed stands is 17 to 25 years. The thickness of the pillar depends on the length of the span and the height of the fence; elements made of solid logs with removed bark are stronger.

Advantages and disadvantages of wood pillars

The wood has sufficient strength and hardness not to collapse from mechanical stress, and the material resists compression and bending loads. Shrinkage can be predicted in advance, since the size changes less along the fibers than across. The conductivity of moisture, steam, sound depends on the direction of the fibrous structure.

Wooden fence posts have a certain viscosity, so they can hold fixing elements inside the fastening; striking strips for locking tongues can be cut into the body of the posts. The wear resistance of the material is determined by the fact that wood, in the presence of impregnations, does not collapse from a sharp change in temperature.

Dry wood does not conduct electricity, so you should not be afraid of a shock if the gate and wicket have an automatic drive with an electric motor.

The use of wood for fence posts is justified by its low cost compared to metal, brickwork, precast concrete elements. It is not difficult to install the fence supports, so the owner of the site can dig in the elements to the depth with his own hands, and perform concreting.

Other advantages of the material:

- availability of purchase;

- beautiful appearance;

- ecological cleanliness.

The disadvantage is that over time, the impregnating layers lose their relevance, you have to regularly process and paint the surface. Wood lasts enough, but its service life is shorter than that of other materials. The bearing capacity does not allow to hang heavy sections, concrete slabs on the posts.

It is necessary to dig in the pillars into the ground, having previously wrapped the lower part with roofing material or coated with molten bitumen so that the pillars do not become unusable from rot. The top of the elements is designed in the form of a cone to speed up the drainage of water.

Selection and processing of pillars

Before installing wooden fence posts, it is necessary to treat with antiseptics in order to extend the service life. The lower part, which will be buried in the ground, must be protected from the action of soil moisture. In addition to modern methods, a folk method of processing with fire is used.

Procedure:

- to comply with the firing boundary, the barrel is wrapped with foil 25 cm wide;

- light a fire;

- the barrel is brought to the flame and rotated for even firing for 10 - 15 minutes;

- after the appearance of blackness and cracks, indicating charring, the pillar is removed from the fire.

For firing in modern conditions, gas burners or a blowtorch flame are used. The height of a wooden fence can be at the level of 1.5 - 2.0 m. Depending on this, trunks are chosen to reduce non-working waste. There are fences of a larger size in height, but the supports cannot be spliced along the length.

Recommended types of wood

The tables are made of oak the longest, they will last several decades without loss of quality. Trunks of other species are inferior to oak in terms of operating time, and require regular surface renewal.

Recommendations for types of wood:

- in the first place after oak are larch, mulberry, pine, acacia, ash;

- spruce and fir are considered lower in quality;

- maple, birch, aspen, linden, alder are considered unsuitable.

Slightly decaying and hard rocks of high density are suitable. Trunks stand for a long time if the wood contains resinous substances that prevent moisture absorption, damage from bugs, microorganisms.

There are planed bars for posts on sale. Specimens with a small number of knots are chosen, since such places weaken the strength. They check fallen out and rotting knots; it is better to refuse such bars. Check the geometric dimensions, pay attention to the curvature of the trunk, darkened areas, the presence of moss on the surface of the element.

Methods and means of protecting supports from moisture

If the fence posts made of wood are placed in the ground, the lower part comes into contact with the soil, absorbs water from it in rainy weather or when the moisture level rises. They are wrapped with moisture-proof materials, coated with liquid molten bitumen, tar or modern polymer-based mastics. Layers are applied 2 - 3, between the application they are kept for a day for hardening.

The aerial part also needs to be treated with antiseptics:

- water composition (5 - 7%) of iron or copper sulfate;

- sodium fluoride;

- creosote oil;

- zinc chloride.

Hexachloran and chlorophos are used against weevils and grinders that infect the material. Impregnation with pyrilax will protect against fire. Water repellents protect against moisture saturation. The funds are applied as an independent layer, sometimes complex compositions of bioprime primers are used, which already contain protection from moisture.

Manufacturing and preparation

If the wood is not edged, it must be dried in natural conditions, folded under a canopy. Drying time is about a year. For construction, specimens are used that have completely ended the drying period.

The bark is removed from the surface. To do this, use an ax, a scraper, a shovel. The trunks are placed in a vertical position so that there is a reliable stop from below. The bark is removed from the top, gradually lowering so as not to damage the trunk body.

If knots protrude on the sides, they are cleaned with a plane, ax, saw. To sand the surface, use an electric tool or use sandpaper attached to a block. Carvings are made on the area of the pillar, a convex ornament is made, if this is provided for by the project.

How to install

A distance of 1.5 - 2.0 meters is made between the posts, for the gate they are placed along the post on both sides, two more supports are prepared for the wicket. If a small passage is made in the alignment of the door leaf, the racks are not marked for the wicket.

The depth of the pillars is taken depending on the weight of the filling of the spans, the properties of the soil. The mark of soil freezing and the height of moisture rise are taken into account. In heaving lands (clays), the installation depth is taken at 1.0 - 1.2 m, and in dry soils (black soil, sand, sandy loam) it will be correct to bury it at 0.8 - 0.9 m.

First, they clean the area along the trajectory of the fence, then remove the fertile soil by 10 - 20 cm. A garden drill is used to excavate the land, but you can dig a hole manually using a bayonet shovel.

Step-by-step instructions:

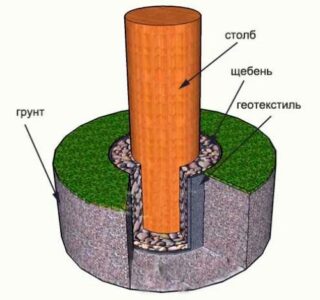

- Sand (5 cm), crushed stone (10 cm) are poured at the bottom of the pit, the layers are rammed and spilled with water for compaction. Materials play the role of drainage, stop the rise of liquid.

- The pillar is set vertically, you can use a plumb line. It is better to work with two people or fix the support in the installation position with spacers.

- The solution is poured into the pit, trying to fill it so that there are no voids. During the procedure, a deep electric vibrator is used. If not, the mass is bayonetted with a metal pin during installation to expel air bubbles.

They constantly check the correctness of the installation along the tensioned cord, and also coordinate the verticality with a plumb line.

The solution is prepared with a concentration of 1: 3 (cement, sand). It should be liquid rather than thick so that it can flow down to the bottom of the pillar.

Typical errors in the installation of wooden poles

If you install the trunk with the butt down, water will intensively rise from the soil along the column due to spontaneous osmosis. The support must be placed with the butt upward in order to disrupt the course of the natural process, to reduce the intake of moisture.

Impregnation with antiseptics and other preparations is done on dried wood, the moisture content of which does not exceed 15%. Violation of the rule leads to a decrease in the effectiveness of pre-treatment of the barrel. If there is water in the pits, it is sucked off with a pump, removed with buckets in order to put supports in the pit without liquid.

They try to bury the heel of the pillar in the sand-crushed stone mixture. A metal support is nailed to the sole of a wooden trunk to increase strength and stability.