Living in a private house is associated with an increased level of comfort. But the absence of neighbors behind the wall or on the top floor is not a guarantee of silence. Sources of noise include cars, nearby construction work, loud music, railways and more. The problem will be solved by soundproofing the house using special materials.

Factors affecting the noise level in the house

Sound is mechanical vibrations and waves perceived by the human ear. Its loudness is measured in decibels (dB). Noise is called random sound vibrations that have a negative effect on a person. Its intensity is influenced by the distance to the source and the reliability of the enclosing structure. Windows and doors are thinner than walls, so most of the street sounds penetrate through them.

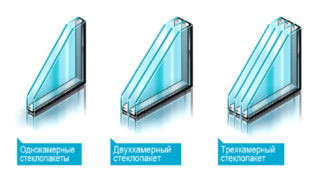

The degree of insulation of window structures is determined by the number of glasses, the size of the air gap between them, the permeability of the joints. For a door, the thickness of the leaf and the tightness of fit to the frame are considered.

To create effective protection against noise, you need to know its features and types:

- Air - Sound waves travel through the air and penetrate open windows, gaps, and crevices. An example is the voices of people, the sounds of cars, music.

- Impact - appears as a result of mechanical impact on the structure (precipitation, falling objects, steps).

- Structural - its source is vibration generated when exposed to a structure (working with a drill, gating).

Noise standards according to SNiP are 40-55 dB during the day and 25-30 dB at night. A parameter below 15 dB leads to a deterioration in the psychological state. Complete silence in the house is not needed, it is enough to achieve the recommended characteristics.

The nuances of the process to improve sound insulation

Street sounds penetrate the room in various ways - through the cracks of windows and doors, through the vibration of the walls, blows on the roof. The installation of insulating materials allows to reduce their impact. Room acoustic protection is of two types:

- Sound insulation - the task of the structure is to reflect the sound wave and prevent it from entering the house. This function is performed by durable materials: brick, concrete, plywood, drywall.

- Sound absorption - the system must absorb the sound wave due to the fibrous or cellular structure of the material. Popular products for this purpose: mineral wool, fiberglass, felt, polyurethane foam.

Before installing noise insulation, it is necessary to inspect the room and determine the places where sounds penetrate. These can be cracks in the walls and ceiling, holes around the outlets. They are sealed with a cement-sand mortar, putting fiberglass inside. What else can you do:

- Install multi-chamber double-glazed windows, replacing cracked wooden windows.

- Fasten an elastic seal around the perimeter of the entrance door. Install MDF panels on the canvas.

- Finish the facade of the house with special materials that will provide insulation and sound insulation.

The above measures only partially solve the problem; in order to ensure a high level of comfort, complete sound insulation of the house will be required. You can do the work yourself.

Noise absorption materials

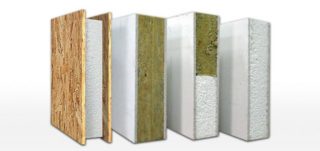

The study of their types and properties will help to choose the right materials for noise insulation in a panel or private house. Products are divided into three groups with different noise protection coefficient:

- Soft - fibrous materials (felt, mineral wool in rolls) noise absorption 0.7-0.95.

- Semi-rigid - cellular and mineral wool slabs (basalt wool, polystyrene, penoplex). Sound absorption 0.5-0.7.

- Rigid - composite materials based on pearlite or pumice. The coefficient is the lowest - 0.5.

When choosing a sound insulator, the material from which the insulated structures are erected, the thickness of the products, the type of noise, the desired level of comfort are taken into account.

ZIPS

The soundproofing panel system is a sandwich made of basalt fiber and plasterboard. It is used in houses and apartments for additional protection against airborne noise. The 70 mm module reduces the indicator by 12-14 dB. The panels have a folded joint; during installation, a frame device is not required.

Noise block

Roll-up soundproofing membranes are known throughout the world as weighted vinyl. In Russia, they are sold under the Shumoblok brand. The thickness of the material is 2.5 mm, it does not take up space during installation. The advantages of the product include elasticity, environmental friendliness, efficiency and affordable cost.

Fiberglass

Fibrous material in the form of slabs and mats has long been used in construction. Fiberglass is laid inside the frame when installing interior partitions, it is used when installing a pitched roof, floor, suspended ceiling. Glass wool slabs are non-combustible, moisture resistant, lightweight and cheap. This is the best option for soundproofing in a wooden house.

Substrates

Cork and foam substrates are laid under the laminate during the installation of the cover. They serve to reduce impact noise performance. Similar materials are glued to the walls under the wallpaper. Substrates provide various acoustic protection, the best option is cork.

Mineral wool

One of the best heat and sound insulation materials for the home is mineral wool. The loose structure and chaotic arrangement of fibers in slabs and mats dampen sound waves. The material is placed outside and inside the room. The popularity of mineral wool is due to its performance characteristics: incombustibility, resistance to deformation, durability. It is used more often than other building materials for insulation and sound insulation in a frame house.

Drywall

An effective barrier to the propagation of acoustic noise will be a plasterboard and fibrous partition. A multi-layer construction is an excellent option for soundproofing a house. Knauf, Volma, Magma companies produce special acoustic drywall. These perforated sheets absorb sound waves well.

Expanded polystyrene

A durable, moisture-resistant synthetic material is suitable for insulation and sound insulation of ceilings, walls, floors. The foam is composed of gas-filled granules, which makes it lightweight. Polystyrene sheets are similar in characteristics to mineral wool, but they are easier to work with. Of the minuses, it is worth noting the flammability of the material.

Features of soundproofing a house with your own hands

Noise insulation in a frame house is carried out during construction or during operation. The features of the process depend on the selected area.

Walls and partitions

To protect against airborne noise, it is better to install a multi-layer structure of alternating sound-reflecting and absorbing materials. The most common option is a partition sheathed with plasterboard sheets, inside which mineral wool slabs, acoustic synthetic winterizer or polystyrene are laid. Installation procedure:

- All cracks and holes in the room are sealed with putty or elastic sealant. Sockets and places of entry of heating pipes and water supply are necessarily insulated.

- A sheet of soundproofing membrane, cut with an allowance, is fixed on the wall. The edges are then wound under the profile.

- Assembling the frame. For the device of the partition, a metal profile is used. Its guides are not attached directly to the surface, but through a layer of vibration damping pad. The substrate is glued with a sealant to the base or self-adhesive tape is taken and attached to the metal. The guide rail is fixed to the floor and ceiling. The rack profile is inserted into it in 60 cm increments.

- Fibrous soundproofing material is laid between the frame posts.

- Plasterboard cladding is carried out, the joints of the sheets are puttied.

- Finishing finish.

There are options for soundproofing using frameless technology: wall cladding with cork roll material, gluing foam to the base, installation of acoustic panels.

Ceiling and slabs

Houses from a bar are often built in 2-3 floors, so you have to take care of the insulation of the floors. Sound absorbing material can be placed between the beams on the attic side or under the suspended ceiling structure.

Frame soundproofing of the ceiling:

- Work is underway to prepare the base (repair, priming).

- The frame is assembled from a metal profile or a wooden bar.

- The space is filled with acoustic mineral wool.

- Plasterboard sheets are attached to the guide profiles with self-tapping screws. A stretch ceiling system is arranged in a similar way.

The disadvantage of the frame technology is a decrease in the height of the room by 10 cm. The use of ZIPS plates with vibration isolation attachments allows for frameless insulation.

Floor

The floating floor system will relieve the propagation of impact noise. According to the technology, hard slabs of basalt wool are laid under the layer of concrete screed, which are covered with a waterproofing membrane. For dry installation, the ZIPS-pol system is recommended. It consists of sandwich panels that are connected according to the tenon-groove principle. Plywood is laid on top of the material, elastic gaskets around the perimeter.

Sequence of installation of a wooden floor:

- The lags are placed on damping rubber pads.

- The space between the beams is filled with bulk materials (expanded clay) or mineral wool.

- Decking made of plywood or OSB boards with a thickness of 15-18 mm is attached to the joists.

- The substrate is laid under the floor covering - cork, foamed polyethylene on a polymer basis.

- Laminate, linoleum or other selected option is mounted.

Using a soft carpet covering is an excellent way to minimize impact noise.

Acoustic comfort in a home is a competent layout and installation of high-quality soundproof materials. To achieve the desired effect, it is necessary to take into account the individual characteristics of the building.