Facade cladding is made from a wide variety of materials. Its purpose is to create an attractive look and to protect the base walls from the action of wind, water, frost, ultraviolet radiation. One of the options for such a finish is metal cassettes for facades.

What are facade cassettes and their main characteristics

The cassette is a box-like design with very low sides. Plates are rigidly fixed with rivets or self-tapping screws on the frame. This ensures the integrity of the finish for a long service life.

Cassettes can be of different shapes: square, diamond-shaped, rectangular, hexagonal or any other arbitrary. They are offered individually, if they have a certain configuration, and in the form of panels 2-3 m long - molded material. The depth of the elements ranges from 10 mm - Euro panels, up to 30 mm.

The facade made of metal cassettes is a ventilated one. Despite the rigid fastening, a gap remains between the cladding and the wall, allowing air to circulate.

Varieties of facade cassettes by material

They produce finishing from metal alloys. Most often it is aluminum, galvanized steel and stainless steel. Copper is less common. The last 2 options are completely corrosion-free and last much longer, but this also leads to their higher cost.

A composite material is also distinguished: cassettes with a polymer interlayer. This model has higher heat and sound insulation properties and is more expensive.

Composite alloys

Such a model is a sandwich: its outer and inner layers are made of metal, and between them is a plastic polymer. The alloy is taken as usual - aluminum or steel. The polymer is glued inside, so that both the glue and the enamel covering the top of the product should be noted as a structural layer.

The adhesive layer provides good fixation, but has much lower technical characteristics and turns into a "weak link". Even steel composite panels last less.

By the type of polymer filling, the finish is classified according to the level of flammability. This parameter must be taken into account when choosing a material and it is necessary to clarify how exactly the flammability test was carried out. Unscrupulous manufacturers perform the necessary tests after having sealed the filler into the cassette. In this form, the product passes the fire resistance test, but in no case does it correspond to the specified class.

For facades, it is allowed to take material with a flammability class G1.

Metallic

Most often, builders deal with aluminum and steel products.

Front metal cassettes made of black steel must be galvanized and covered with an anti-corrosion coating. Powder paints are used for painting. This coating protects the steel from corrosion and lends an attractive finish.

The steel cladding is mechanically very strong, is not afraid of frost or sun, and retains perfectly clear and precise forms.Usually small cassettes are made of steel and used for cladding strict architectural forms.

Metal cassettes made of stainless steel are much more expensive, but this finish does not need protection and is not afraid of rust.

Aluminum plates are no less durable, fireproof, but less durable. But aluminum does not corrode even at the highest humidity and has a naturally beautiful shine and color. The aluminum finish is much lighter making installation easier. It does not create a lot of stress and is used to decorate old buildings.

Copper cassettes are extremely rare. They do not corrode, are extremely beautiful, but also very expensive.

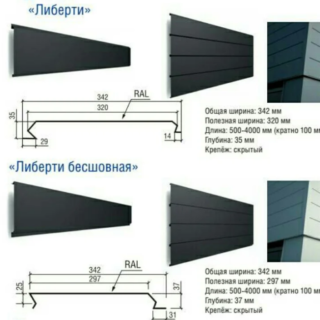

Linear

A kind of volumetric metal profile made of galvanized steel by rolling. A distinctive feature of the product: the protective coating is applied by cold forming, which guarantees its high resistance.

The linear panel is called because of its shape: its width is much greater than its length.

Advantages and disadvantages

Aluminum or steel cassettes for the facade have considerable advantages, which makes this material more and more popular:

- The cladding is very durable, it is not afraid of impacts and scratches.

- The assembly is carried out very quickly due to the optimal shape and fastening technology. For cladding a small building, there is no need to hire a special team.

- They are insensitive to cold, wind, rain, UV and protect the base material of the wall.

- The metal finish is fireproof, insensitive to temperature fluctuations.

- The finishing weighs a little compared to clinker or stone ventilated facades, so it does not put stress on the walls and foundations.

- The veneer creates a flat surface. Visually, this allows you to hide a lot of defects.

- The service life is over 50 years.

The disadvantages of facade cassettes are due to the design and material of manufacture:

- Steel plates are heavier than aluminum ones; during their installation, a reinforced frame will need to be built.

- Aluminum is more expensive than steel. You need to work with them carefully, since the alloy is soft and if mishandled, the tiles can wrinkle.

- Composite products are sensitive to heat and sun due to plastic accumulation. When choosing, you need to carefully read the characteristics of the products in the instructions.

The color of the finish is limited only by the color range of powder paints. The texture is only smooth.

Types of fasteners

Installation of a metal facade is carried out in 2 ways: open and closed. In this case, cassettes of different types are used.

Open

A simple and cheap way. The profile is fixed through a hole in the profile with self-tapping screws directly to the supporting frame. Surface-mounted boards have curved edges, in which holes are drilled. The advantage of this solution: the ability to dismantle the cladding at any time and install it on another site. Moreover, this does not require any special tools.

In the event of damage to individual panels, repairs are carried out very quickly.

Hidden

In this case, a smooth, seemingly seamless finish is obtained. Each cassette is screwed with the upper part to the frame, and the lower one is inserted into the groove of the lower plate. In this case, the joint is invisible. These models have only one curved edge with holes.

The disadvantage of the hidden ventilation facade is the impossibility to dismantle the finish without damaging it. The repair is extremely difficult as only a couple of damaged sheets cannot be replaced.

Application of facade cassettes

Cassette metal facade is used in the following cases:

- cladding of industrial buildings - the finish is strong and durable, does not affect the temperature regime inside the structure;

- exterior decoration of administrative and shopping complexes - here they try to choose a more decorative profile;

- renovation of old buildings - a metal facade allows you to do without expensive wall restoration;

- metal cassettes can also be used for interior decoration: facing columns, ceilings, walls.

In private construction, cassette decoration is used extremely rarely: it gives the building a distinct "urban" look, poorly compatible with the surrounding landscape.

Installation features

Installation of metal facade cassettes is carried out after the installation of the lathing and its vapor barrier.

Procedure:

- The surface of the facade is marked according to the dimensions of the cassettes and the points of attachment of the brackets are indicated. The markup starts at the bottom.

- Holes are made according to the marks, brackets are installed and fixed with anchors. If the dimensions of the sheet exceed 70 cm, you will need to install an additional profile and, accordingly, an additional row of brackets.

- The battens of the battens are fixed to the brackets with bolts. The lathing is carried out immediately on the entire wall in order to pull off the entire structure as a whole.

- Typically, a thermal insulation pad is placed at this stage. In regions with warm climates or when using composite cassettes, insulation can be dispensed with.

- The frame is vaporized. It is better to use special membranes.

- A vertical profile is mounted, the ebb is fixed and the starting profile is fixed at the bottom.

- Installation of cassettes begins from the lower left corner for flush mounting, or from any place with an open method.

- Each element is reinforced through the holes with self-tapping screws, observing the installation technology.

- The installation is completed by attaching the finishing profile.

The assembly of the cassette façade does not require sealing the seams and is very fast.

Facade cassette production

The production of metal cassettes is carried out only in a production environment. Its essence lies in stamping a blank from a sheet with a thickness of 0.5 to 1.5 mm. The sheets are then cut to size and folded into the desired configuration.

Flexion is done in stages. Immediately after cutting, the contours of the cassette are formed on an angle-cutting machine. Then, on a bending equipment, it is given its final shape. Finished products are coated with powder paint, if provided.

The quality of the projection is controlled at every stage.

Metal facade - a variant of the ventilated finish. The cladding protects the wall material from the effects of rain, snow, frost, ultraviolet radiation and provides sufficient air circulation to prevent mold or condensation.

We studied for a long time what to take for the cladding of a store in the Moscow region, settled on metal cassettes. Bought from manufacturer, came out with a discount and a guarantee.