During the preparation of kebabs, fat dripping onto the wood provokes an increase in the concentration of benzopyrene in the smoke. It is the strongest carcinogen with mutagenic and teratogenic effects. This problem can be avoided by making a vertical brazier with your own hands.

What is a vertical barbecue

The design of the vertical type differs from the classical one in that there is no direct contact between smoke and meat. Cooking is carried out due to the heat emanating from the fuel, and the combustion products are removed separately.

Brazier types:

- Side. The combustion chamber is located along the wall, and products strung on skewers are attached opposite it.

- Central. A cylinder or rectangle made of steel mesh is attached along the geometric middle of the body to its bottom. Attachments are installed on the inner walls for stacking or hanging skewers.

Variants and placement of skewers:

- Horizontal. As a rule, it is used for products with a lateral lesion. The skewers are placed on the cutouts of the protruding walls and periodically scrolled and swapped.

- Vertical. This method is used in structures with a vertical orientation. The rods are suspended in slots made on the cornices along the top of the walls.

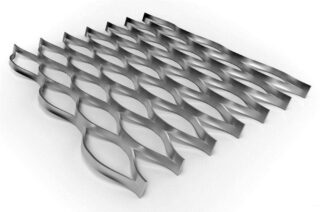

Pallets are placed at the bottom of the barbecue. The canvas under the hearth is made from a notch made on CNC machines. The size of the cell allows ash to sink through, but retains the coals. A continuous tray is placed under the food, into which fat and juice flow down.

Benefits of a vertical barbecue

The vertical circular brazier has the following advantages in comparison with horizontal counterparts:

- Capacity. On average, it is 2-4 times higher with the same weight and size.

- Safety. There is no contact of smoke with food, it is protected from the ingress of carcinogenic substances.

- Functionality. At the same time, you can cook fish, vegetables, pork, poultry. They will not touch each other, interrupting each other's smell.

- Practicality. The arms are designed to move food closer or farther to the coals for better results.

You can make a vertical type metal brazier yourself, without special skills and tools.

Types and design features

There are such types of vertical barbecues:

- Portable. The structures are small in size. Subdivided into transportable and wearable. The collapsible one weighs only a few kilograms and when folded fits into a backpack or a case of the "diplomat" type. Great for backpackers.

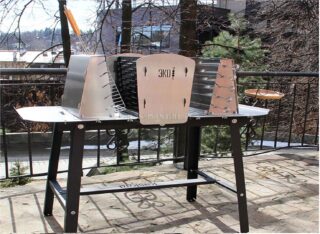

- Stationary. The structures are large and massive. They are installed on a previously prepared platform on supports or embedded in the foundation. The metal is taken with a thickness of 4-6 mm, which ensures long-term use. Decor elements in the form of overhead forged parts and engraving are widely used.

- Open. They represent a light frame with a grid for fuel and side supports for skewers located next to each other. They are lightweight, for the most part they have a collapsible device. The downside is low efficiency and potential for contamination.

- Closed. The products have a case completely closed on all sides, with brackets located on the inner walls.Almost all thermal energy is used, and the closed configuration protects the interior from dirt and wind.

The possibility of precipitation should be foreseen when using the barbecue A small removable tin cover will not be superfluous.

How to make a vertical barbecue from metal

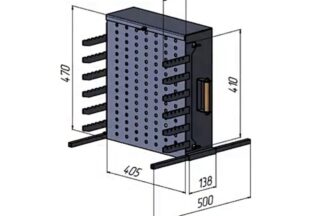

The initial stage of work is design. To make a good vertical barbecue, the drawing must be done competent and detailed. On the basis of the plan, an estimate is drawn up and the calculation of materials is carried out.

Tool list:

- Bulgarian;

- level;

- welding;

- drill;

- roulette;

- square;

- pliers;

- spanners;

- screwdrivers.

List of materials:

- sheet steel, preferably stainless steel or refractory alloy;

- profile pipe 20x40 mm:

- corner 30x30 mm;

- notching;

- electrodes;

- bolts with nuts;

- paint brush;

- refractory paint.

For the installation of a stationary structure, you will additionally need concrete, paving slabs and reinforcement.

The brazier should be made in the following sequence:

- Spread the iron on a flat surface, mark it in accordance with the diagrams. Recheck the accuracy of the lines.

- Cut sheets and notches, cut blanks for walls and bottom. It is better to do this with a grinder, first with thin discs, and then with grinding wheels to level the edges and remove burrs.

- Assemble the grid. Depending on the availability of tools and skills in working with them, this is done by welding or bolted corners.

- Attach the firebox to the bottom, in which an ash hole was previously made. Here, too, a convenient method is chosen.

- Assemble the casing walls. Treat joints if welding was used. Attach corners around the edges, which will be used as suspensions for skewers.

- Dock the bottom and casing modules. Grind off protruding parts, grind corners.

- Assemble the support system. These can be legs fixed to the body or a frame on which the bowl assembly is installed. The second option makes it possible to remove the barbecue and replace it after wear.

- Attach decorative fragments to the product. For fixing, you can use welding, bolts, rivets.

In conclusion, the structure must be cleaned of dirt, rust and scale, then primed and painted.

Terms of use

In your own yard, you should prepare a part of the territory for the barbecue. The presence of a platform and tracks is assumed. A small canopy will not hurt to protect the person and the grill from precipitation.

The ignition must be carried out in a grid with paper and dry chips. As combustion intensifies, add larger pieces of fuel.

You can lay skewers after the flame has died out and embers have formed. In the process of cooking, the kebabs need to be turned over and swapped.

After the end of the picnic, you must not fill the hearth with water, as this is fraught with deformation and cracks. When the stove has cooled down, it must be cleaned of ash. This substance, upon contact with water, becomes chemically active and provokes metal corrosion.