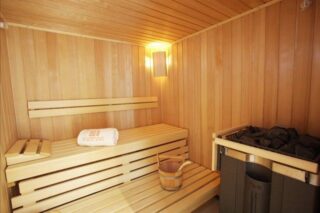

The bath from the inside is often trimmed with clapboard. This is a rational choice: wood paneling keeps the temperature inside the room, does not get very hot, and retains a beautiful appearance. Wooden slats are laid and fixed in different ways.

Choosing a wooden lining for a bath

Not every lining is suitable for covering the steam room and sauna. In the washing room, it is also better to choose a tree of only certain species. There are no restrictions for decorating a dressing room or a guest room.

In the steam room and sauna the air temperature reaches high values - 80–110 ° С. The wood must maintain its qualities at this temperature and not get very hot, otherwise the shelves will be impossible to use. In the steam room and washing room, the humidity is also high, therefore, only rocks that are resistant to water and steam are suitable for decoration.

Only wood that is resistant to decay and mold is allowed. It is impossible to process the material in the steam room with paints or varnishes, and oil and wax are not good protectors of wood.

The following breeds meet these requirements:

- linden - resistant to water and steam and has a wonderful smell;

- aspen - does not lend itself to mold and becomes only harder over time;

- cedar - soft, plastic wood, has pronounced antiseptic properties;

- birch - used only for the sauna;

- oak - absolutely resistant to water and steam, but expensive.

You cannot take coniferous wood for finishing a sauna or steam room. It contains many resins, and under the influence of temperature, the latter is released on the surface. Walls, shelves become dirty, sticky, and resin, unlike wood, heats up much more.

The difference between ordinary and eurolining

The lining differs from the usual one, first of all, in its configuration. The groove is deeper, the ridge is higher, which provides a stronger and more tight joint of the lamellas. Ventilation grooves are cut on the surface of the elements, therefore, after installation, it does not lead to changes in humidity and temperature. Thanks to these qualities, the lining can be considered the best option for a bath.

Preparing walls for cladding

To properly fix linden or aspen lining in the bath, you need to carry out preparatory work. Installation of finishing is the last stage of work.

- Start by cleaning the walls and marking under the crate. For euro lining, calm or American women, they take a wooden, well-dried timber with a section of 2 * 5 cm. For a block house, a more massive version is needed - with a section of 5 * 5 cm. The distance between the slats is 40-50 cm.

- A gap of 10–15 mm is maintained between the edge of the lathing timber and the floor. It is needed for ventilation.

- Bars-amplifiers are placed on the frame. Shelves are mounted on them.

- The step is determined not so much by the configuration of the lining as by the width of the insulation sheet. The standard size of mineral wool is 60–70 cm. It is easy to put it into the resulting cells. For foam boards, the step can be increased.

- Insulate the material with a foil coating. The latter protects the frame and insulation from the action of water and steam, reflects heat back into the room. Attach the cover with the shiny side inward.

- The gap is covered with a wooden plinth.

When cladding the walls and ceiling of the steam room or washing room, a metal profile must not be used.Its coefficient of thermal expansion is very different from that of wood. This leads to deformation of the lining and walls.

Lining mounting options

You can fix a lining or other profile in the bath in different ways.

- Through fastening on nails or screws with masking is the easiest option. For fasteners, holes are pre-drilled in the lamellas so that the lining does not crack during installation. During installation, a nail or self-tapping screw is inserted into the hole and sunk flush with the surface. The fasteners go through the lamella body and damage it. The disadvantage of this method is the high risk of getting burned if the user accidentally touches the almost invisible hats.

- Hidden connection with self-tapping screws means masking the fasteners. In this case, the self-tapping screw is completely recessed into the material, and the hat is closed with a wooden chopik. After installation, the ends of the plugs are ground flush with the surface. Since the metal is covered with wood, there is no risk of burns.

- You can also nail the slats through the groove with nails. But unlike self-tapping screws, they sink into the material at an angle of 30–45 degrees so that the cap sinks flush with the spike. In this case, the spike of the next lamella completely covers the nail.

- Concealed fastening on cleats is the safest. In this case, clamps are put on the thorn, and nails or staples are driven through them. The tree is minimally damaged.

The method is chosen depending on the budget and further intentions. Fastening with nails through the lamella does not require any additional effort. However, the material here is damaged irreversibly; the lining cannot be reused.

Installation with clamps does not damage the material at all, since the fasteners go through the fixture directly onto the frame.

Installation methods

The material is represented by long, narrow lamellas. Their placement on the wall greatly affects the visual perception. The following methods are used in the bath.

- Horizontal - visually expands the room, but makes it slightly lower. Suitable for large steam rooms. In addition, this position of the lamellas prevents drying and deformation of the wood.

- Vertical - visually raises the ceiling, therefore it is used more often. However, from the practical point of view, the method is less profitable. Boards in the lower and upper parts are subjected to different thermal loads, which leads to deformation.

The diagonal placement method is rare. It looks beautiful, but requires a lot of material and maintenance.

Ceiling sheathing

Ceiling mounts are a little more difficult due to the need to work together. You can do it yourself. In this case, stands are purchased or made from a bar of 5 * 5 cm, with which the fixed lamella is supported.

Since there is no danger of getting burned here, you can fasten it with the simplest method and not worry about camouflage. But it's important to level the boards. This is done using a rubber or wooden tip doboynik. The lamellas should fit snugly against each other, while the hammer makes a dull sound.

When installing the last lamella, it has to be cut, since the standard width rail does not fit into the left cavity. This is done with a circular saw. The joint is covered with a ceiling plinth.

How to sheathe a doorway with clapboard

Slopes can also be repaired with material. Lamellas are fastened to wooden blocks located perpendicular to the direction of laying. Which method is better - vertical or horizontal - determines the amount of material remaining and its quality. It is easier to get the desired number of fragments from short cut pieces, but finishing will take longer.

- For vertical installation, the lamellas begin to be installed from the door frame. The board is pressed into the frame with a groove and nailed with finishing nails. The next lamella is inserted with a tenon into the groove and fixed in the chosen way.

- When laying horizontally, a starting profile is placed on the frame, and the installation itself begins from the bottom. First, the fragments are fixed in the groove of the starting bar, and then between themselves.

To mask the gap between the sheathing of the slope and the walls, use a wooden corner. They put it on nails or even glue.

Installation of lining near the sauna heater

The stove in the steam room is installed near one of the walls. Since a cast iron or steel product is very hot, different requirements are imposed on the finish here.

Directly next to the stove, the wall is sheathed with clapboard in the usual way. Stones accumulate heat, so they don't get very hot. The possibility of fire is small here.

The place around the firebox along the perimeter of 3 walls of the case is sealed with a metal, minerite or asbestos sheet. These materials are not flammable and even if coal gets from the firebox to the floor, they do not allow a fire to start.

The wood dries out and is not worth fixing on dead.