Oriented particle boards made from wood chips are widely used for interior and exterior wall decoration due to their low cost and ease of installation. This material can be used not only in residential areas. The OSB garage cladding from the inside will make the room comfortable for staying during car repairs and working in the workshop.

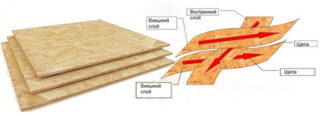

What is OSB plate

The raw material for OSB, as well as for chipboard, is wood chips. Both conifers and some deciduous species, such as maple, are used. The dried shavings are mixed with resinous compounds of natural and synthetic origin and laid in layers. Then the material is compressed. The result is a slab body. It is trimmed to conform to the standard dimensions.

Slabs are on sale with different characteristics, sharpened for a specific field of application. They are usually divided into 4 classes.

- First-class products are the cheapest, but inferior in strength and moisture resistance to other options. It is suitable for the manufacture of furniture and packaging, but it is not worth purchasing for interior decoration.

- Class II products are stronger, but still susceptible to moisture. It can be used in rooms with dry air.

- Plates of the third class (OSB-3) are sufficiently moisture resistant. It is with them that it is preferable to sheathe the room from the inside.

- OSB-4 boards have the best performance, but also a rather high price. If the homeowner wants to finish the OSB room from the outside, it is better for him to prefer this option.

In the production of OSB, resinous compositions containing formaldehyde are often used. In this regard, fears are sometimes expressed about the possible harmfulness of cladding with plates for the health of residents.

There are two classes of content of this substance in products: E1 and E2. This division exists both in Russia and in Europe, while the requirements of Western companies are noticeably stricter. To category E1 they classify material with a gas content of up to 8 mg per 100 g, to E2 - 8-15 mg. Russian standards regulate the presence of less than 10 mg of formaldehyde in the composition for class E1, and 10-30 mg for E2.

To be sure of the safety of the product, it is worth purchasing European class E1 plates and paying attention to the substance content. If the homeowner wants to sheathe the garage from the inside of the OSB or otherwise use the material for finishing non-residential buildings, he should not worry, since these premises are not a place of sleep or permanent residence.

Some companies have already started producing boards that do not contain formaldehyde at all. They can be distinguished by their “Green” or “Eco” markings.

Pros and cons of the material

Plates are easily cut without crumbling and are mounted on the lathing. Other advantages of the material include:

- low price;

- attractive appearance;

- sufficient strength (but for a sheet of plywood of the same thickness, it is greater than that of boards of any class, except for the fourth);

- thermal insulation qualities;

- resistance to mold and fungal colonies;

- good moisture tolerance, if it does not get on the plates regularly and in large quantities (if you use OSB-3 for exterior decoration of the room, after 5 years the material will be seriously damaged).

The disadvantages include the formaldehyde content in the composition and swelling with delamination with regular exposure to moisture. Due to the latter factor, slabs (except for the fourth class) should not be used for external cladding. It is possible to decorate a garage room and other non-residential buildings from the inside that are sufficiently protected from rainfall without any fear.

Separately, it should be said about the degree of flammability of the material. The newly purchased slabs of the third class almost do not have this property, although they are charred in the fire. As the plates are used, this feature comes to naught. Scraps of material purchased 5 years ago are highly flammable.

Ceiling and wall cladding

To sheathe the garage from the inside of the OSB with your own hands, you need to calculate how many plates you need to work on. To do this, you need to have a project drawing on hand. You can divide the area of the walls and ceiling into the dimensions of one unit.

When finishing the garage, an expansion gap of 3-4 mm should be left between adjacent tiles in case of deformation of the material from moisture or temperature drops. During finishing work, it is filled with sealant. Distribute products so as to avoid cross-shaped connections. Then the structure will be stronger.

How to make a crate correctly

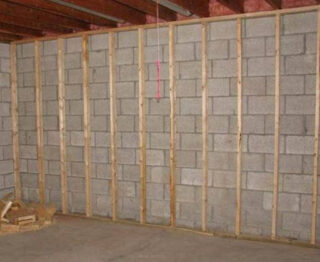

The frame structure can be made of metal profiles or wooden beams. If the garage has a modest size, it is better to opt for a crate - it will "eat" less space. Otherwise, it is better to prefer a frame - it will allow you to insulate the walls with mineral wool. The rules for installing the lathing and frame are similar to those used for sheathing with other sheet and panel materials.

If it is decided to make a structure from a metal profile, the guide elements are attached around the perimeter, and the rack-mount ones - on a plane. For fixing, you will need to purchase suspensions. If a timber is used as a raw material, it is strengthened around the perimeter, and then vertical racks are mounted. For fixing wooden elements to the wall, galvanized corners are suitable. First, the position of the bars is marked, fasteners are placed on it and fixed with self-tapping screws.

If the wall is made of brick or block material, this method of fixing is possible: holes are drilled in the timber corresponding to the size of the dowel, with a distance of 30-40 cm between them.Then the wooden element is placed against the wall and the corresponding holes are created in it with a puncher. Dowels are placed in them and self-tapping screws are screwed in. The easiest way to fix it is if the wall is also made of wood - in this case, no additional tweaks are required.

How to fix panels to the wall

The slabs are attached to the crate with long self-tapping screws. It is better to do this work with an assistant, since large slabs are quite heavy. The caps are immersed in the surface by 2 mm, and the joint areas between the adjacent parts are sealed with a sealant on acrylic. The composition on silicone is less suitable, since paints are worse on it.

For the outer coating, a transparent or tinted varnish that is resistant to high humidity is suitable. Before applying the composition, the surface is first treated with fine emery paper, and then primed. The use of such a composition will prolong the life of the skin and prevent it from swelling due to moisture.