Wood is the most popular building material. Not only residential buildings are erected from it, but also outbuildings. A wooden garage is durable, beautiful, cheap, its construction takes a minimum of time and effort.

Types of wooden garages

Depending on the type of material used, there are 3 types of buildings in the country.

- Log house - erected from tree trunks - solid or planed. Such a building is unusually beautiful, very strong and durable. An ideal microclimate is maintained inside: here the car is not threatened by excess moisture and corrosion. However, building a log house requires high qualifications. In addition, a structure made of logs sits down for a long time, so it should stand empty for at least a year.

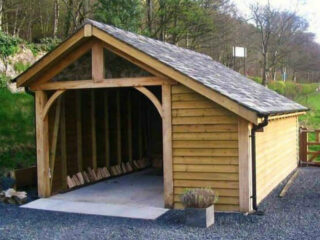

- Prefabricated - a lightweight building with a shed or gable roof. It is erected from a bar. This profiled element is rectangular in cross-section. It is much easier to install, so installation takes much less time. The beam shrinks less, the building can be used immediately after construction. In terms of strength, the prefabricated structure is not inferior to a log house. The microclimate here is retained worse, the timber retains heat less, but since a high temperature should not remain in the garage, this cannot be considered a disadvantage.

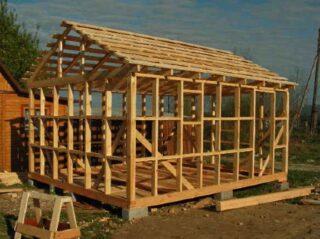

- Frame - a budget option, the easiest and fastest to assemble. A wooden frame is erected on a light foundation and sheathed with boards, corrugated board, clapboard, sandwich panels. If a warmed version is required, it is easiest to build a wooden frame garage with your own hands.

The more weight the building has, the heavier the foundation it needs. This increases the cost of construction.

Pros and cons

Wooden garage boxes have many advantages:

- lightness - a pile or strip foundation is suitable;

- good thermal insulation properties compared to building stone;

- strength and durability - the structure is designed for 30-50 years of operation;

- installation speed - construction requires a minimum of costs and time.

The disadvantages are significant:

- The wood burns, and treatment with fire retardants does not solve this problem. The box is necessarily equipped with fire extinguishers, a fire shield with equipment is placed next to it.

- The placement of a wooden structure in a summer cottage is strictly regulated by SNiP.

- The tree is afraid of high humidity. The danger is represented by both external factors - rain, snow, and internal - condensation falling on the walls. The material should be protected: varnished, painted, treated with antiseptic impregnations.

A timber structure, and even more so a frame one, does not allow heavy equipment to be fixed on the walls. It is difficult to equip a car repair shop here.

How to choose a place for a garage

The location of a garage made of wood or a log house is determined by the norms of SNiP and fire safety. Restrictions are strict:

- if the main house is reinforced concrete, the garage should be 10 m away from it;

- if there are wooden floors in a residential building, the distance increases by 2 m;

- if the house is also built of timber or logs, the distance between them reaches 15 m;

- the distance to the house in the neighboring area is calculated in the same way;

- the garage must be 1 m away from the fence if other restrictions are met.

You should also consider the distance from the carriageway or main road.If the site faces the street, from the edge of the carriageway to the foundation of the building should be at least 3 m, if on the highway, then 5 m.

Schemes and drawings

To quickly and easily build a garage with your own hands from wood, you can build a frame structure. Construction begins with planning. Determine the purpose of the building, capacity, presence or absence of windows, attic on top, type of roof, material. Then the drawing is displayed in the figure in the appropriate scale.

Scheme development rules:

- The floor plan and its dimensions depend on the dimensions of the machine. It should be taken into account that there must be at least 30–40 cm between the walls and the car body, and at least 30–50 cm in front of the bumper.

- Determine the location of gates, windows, hoods.

- They plan communications if it is supposed to heat the building.

- A list of nodes and materials for them is given on the diagram.

- If the roof is complex enough, it is recommended to make a separate drawing for it.

Compulsory work includes the choice of the foundation. Usually a circuit is not needed for it. But if you plan to equip the drainage system, it is worth creating a drawing for it as well.

Using a plan makes it much easier to calculate the amount of materials and make an estimate.

Required tools

To build a frame garage made of wood, you will need:

- a bar for the main beams and racks (it is recommended to take double boards instead of a bar);

- sheathing material - lining, boards, sandwich panels;

- concrete and crushed stone for the foundation;

- roofing material - tiles, ondulin, slate;

- shovel, hammer, saw;

- level, plumb line, tape measure;

- an electric drill with attachments or a construction mixer;

- screwdriver and sander;

- fasteners.

Other materials and tools will be required to install gates and windows.

DIY wood frame garage construction

How to build your wooden garage depends on its design, material and site characteristics. The latter greatly influences the choice of the foundation. Sometimes, due to the heaving moving soil, even such a light building has to be placed on a slab foundation.

The garage project can be ordered or checked by specialists. It's safer this way.

Step-by-step construction instructions include the construction of the foundation, frame, cladding, external and internal decoration, and other work.

- Prepare the site: align, remove a layer of fertile land, mark the diagram on the ground.

- Dig a trench for a shallow strip foundation. A layer of crushed stone and sand 20 cm thick is tamped to the bottom. Formwork is placed and poured with concrete. It is recommended to reinforce the structure with iron reinforcement.

- After complete setting, after 3-4 weeks, the foundation is waterproofed and the lower strapping is installed: a wooden beam or boards are attached to the base.

- Install the wall frame. 2 options are allowed: fix each rack to a separate element, or mount the entire wall frame at once and install it as a whole.

- Tie the frame with the upper harness. Lay the transverse ceiling beams. At the same time, they build flooring or prepare a base for a concrete screed.

- Install the truss system on the upper trim.

- After the frame is fully constructed, the walls and roof are sheathed with selected materials: chipboard, plywood, boards, timber.

- If necessary, finish the garage outside - clapboard, siding. If desired, the room is finished from the inside.

- The gate is installed last. The design can be any: swing, sliding, lifting gates.

You can insulate a wooden garage both outside and inside. Insulation works are performed simultaneously with interior or exterior decoration.