Construction technology assumes that constant and temporary loads are perceived not by walls, but by racks and beams of a volumetric frame. The walls between the vertical elements are sheathed with a bar, boards, boards, OSB plates, and a heater is installed. The method is suitable for those who decided to build a frame bath with their own hands in order to do the job quickly and provide functionality at a high level.

- Pros and cons of a frame-based bath

- Construction technology

- Material for the construction of a frame bath

- Tips for choosing building materials

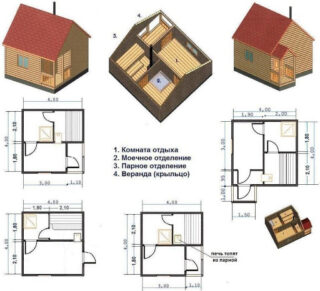

- Projects of frame-panel board baths

- How to build a frame bath

- Foundation device for a frame bath

- Assembling the walls

- Roof construction

- Floor arrangement and finishing

- Internal work

- How best to equip the oven

- Thermal insulation scheme for a frame bath

- Drain device

- Installation of proper ventilation in the bath

- Finishing

Pros and cons of a frame-based bath

The structure consists of vertical supports, intermediate girders, connecting struts and dowels. After the completion of the assembly, the frame elements work in compression, do not receive bending loads, therefore, the operating time is extended.

Positive aspects of construction:

- light weight does not require a buried foundation;

- there is a large selection of materials for decoration;

- can be built all year round;

- ecological cleanliness of a wooden building.

The disadvantages include dependence on moisture, fire. Before starting the installation, the lumber is treated with safety drugs.

Construction technology

External supports are mounted according to the layout scheme, connected to each other by horizontal and diagonal ties. The vertical posts are supported on the lower beam strapping, and they are connected from above with bars. Supports are placed in increments of 30, 40, 60 cm, the basement and upper chord is made of parts similar in cross-section to the racks. Internal and external coverings are attached to the vertical elements of the frame.

Details are supplied with cuts, grooves and spikes for the convenience of assembling the bath frame. The modular version of the standard design comes disassembled with precisely fitted connections and detailed instructions. Elements do not need to be finalized in place for phased docking.

Material for the construction of a frame bath

Traditionally, baths next to a house or summer cottage are built of wood. Profiled beams are used more often. If they want to reduce the cost of construction, they take debarked logs and uncylinded bars. For racks, conifers are used, maple is used.

Wall cladding is combined, using ceramic bricks or large-sized blocks of aerated concrete and foam concrete. Bricks use clinker, hollow, take fired clay. Slip, mud bricks and silicate bricks are not used for the construction of bath walls.

Inside the building is insulated with glass wool, some types of polyurethane foam, outside they put foam plastic, expanded polystyrene, mineral wool.

Tips for choosing building materials

Small buildings are erected from a square bar 15 x 15 cm, for large ones they take a section of 15 x 20 cm or 20 x 20 cm. Sometimes an I-beam is used - two long beams with a jumper between them. The moisture content of the scaffold at the time of installation should not exceed 18%. Sometimes they build a bath from a metal frame.

Materials for laying the gaps between the posts must meet the necessary requirements for the construction of baths:

- resist the action of moisture;

- do not react to atmospheric factors;

- be strong and durable.

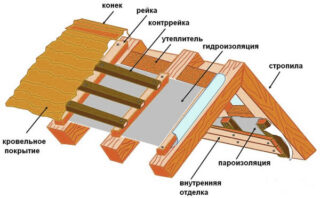

The roof is made with wooden rafters and lathing; corrugated sheets, metal tiles, slate are chosen for covering.

Projects of frame-panel board baths

Drawings and calculations are done so that the construction of a frame bath with your own hands is exactly in size, and the connecting nodes are made without distortions and gaps.

There are drawings in the project:

- plans for the location of racks, foundation piles or concrete tape;

- side cuts give an idea of the elevation marks of the height of the racks, ties, girders, roof parts;

- separately drawn nodes show options for connecting elements.

Typical projects are often used, they are tied to existing conditions.

How to build a frame bath

They bring in materials for the calculations of the project, study the assembly scheme. Prepare the site and build the foundation.

DIY step-by-step instructions for building a 3x4 frame bath:

- build the lower belt;

- put logs for arranging the floor, rough flooring;

- make waterproofing, vapor barrier, put insulation;

- mount racks, diagonal braces;

- carry out the transom under the attic;

- install roofing elements (beams, trusses, rafters).

Insulation is laid, lathing is placed, the coating is mounted, then communications are laid, interior and exterior decoration is made.

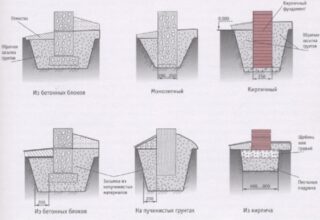

Foundation device for a frame bath

A 40 cm wide trench is dug 0.7 m deep. Geotextiles are laid at the bottom so that the edges are then closed on top of the crushed stone bedding. Sand and crushed stone (5 and 10 cm, respectively) are poured at the bottom, rammed. Drainage holes are provided in the corners.

The formwork is made of boards, boards, props are made of rails. Roofing material is laid, its edges are brought vertically onto the walls. Reinforcement is laid with rods with a diameter of 10 - 12 mm. Concrete is poured into the formwork, driving the mixture with a trowel into the gaps between the reinforcement. An electric vibrator is regularly used to get rid of air bubbles.

Assembling the walls

Prepare the same type of racks and runs in size. The lower belt is arranged over a layer of waterproofing on the surface of the foundation. To do this, put three layers of roofing material, glue on resin or ready-made mastic. The supports are mounted separately each or the enlarged units are joined at the bottom, then raised to the mounting position.

The bars are joined in the frame in a half-tree way. If boards in two layers are used on the upper harness, they are connected in a similar way, but an additional corner bunch is used.

Roof construction

A gable or pitched roof is being erected. In the second version, higher supports are mounted on one side, on which inclined beams are attached. For two slopes, trusses are made, and the racks are made of the same height. The flat roof version is also made with a small slope (10 - 15 °).

Structural elements are impregnated with an antiseptic before installation. Roofing parts are bolted together, brackets, steel and wooden studs are used. The step of the rafter legs is chosen in accordance with the project, taking into account the weight of the coating, the magnitude of the wind and snow load.

Floor arrangement and finishing

If the floor is wooden, at the stage of the lower strapping, logs are placed to fix the boards. Lags give additional rigidity and strength to the lower part of the frame.

The floor in the bath is made of four types:

- wooden flowing type;

- solid from boards;

- concrete;

- concrete heated.

In the first case, water flows into the ground under the floor or into a drainage pad. In other options, a slight slope is made, and a funnel is mounted below for receiving water. Careful waterproofing of the coating and insulation is required.

Internal work

In the bath, the wiring is made internal, hidden in plastic troughs, it is not allowed to place power cables in metal boxes or steel-braided hoses. Lamps are used with moisture-proof cases, sockets and switches are not installed in the steam room, only in the dressing room.

Plumbing is laid in the ground if the bath is operated all year round. Pipes are placed taking into account freezing, insulated with insulation. With only summer operation, an air method of supplying water in a hose is allowed, but with the onset of cold weather, the liquid is drained from pipes, a tank and a toilet siphon.

How best to equip the oven

The remote firebox works rationally, which is connected to the steam room with a channel for supplying heated air. The oven requires a separate brick or reinforced concrete base. In the wall of the dressing room, adjacent to the steam room, a channel is cut down, which is lined with bricks with thermal insulation.

A chimney with a roof outlet is installed vertically.

The place for the combustion channel is chosen so as not to reduce the space for the shelves in the steam room.

The furnace foundation is insulated with a heat-resistant insulator, for example, fiberglass, asbestos. A metal sheet is stuffed in front of the oven door.

Thermal insulation scheme for a frame bath

Types of insulation are used that do not emit toxic components in conditions of humidity and heat. Mineral wool mats are saturated with moisture and lose quality, so they need a ventilated gap between the insulation and the waterproofing.

The foil look works well. It is placed with its shiny side into the room so that the thermal infrared rays are reflected back into the room. The foil is chosen according to the thickness of the walls, the screen is placed separately or together with a standard insulation. Reflection of heat significantly reduces fuel volume.

Drain device

The amount of effluent depends on the area of the bath, the intensity of use.

The drain is organized in the following ways:

- liquid intake into the ground under the floor;

- discharge through a system with drainage wells;

- use of a cesspool;

- the use of a septic tank system;

- tie-in to the city sewerage system.

Pipes in the ground are insulated from freezing, placed at a slope towards the receiving sump. Timely drainage of water helps to avoid mold, mildew and deterioration of floor structures. For the bath, a separate sewer is made or a pipe is brought out into the general drainage system to septic tanks.

Installation of proper ventilation in the bath

Three types of ventilation systems are used in the bath complex:

- natural excretion and delivery;

- compulsory way;

- air purification and recovery system.

In the first case, the air leaves and is supplied through built-in or hinged ducts. The forced method involves the use of fans. They are mounted at the input of the output and the output of the supply channel. A complex cleaning system is used in large establishments; it is not installed in private buildings due to its high cost.

Finishing

Wood floors are impregnated with linseed oil to reduce moisture penetration. Concrete floors are finished with ceramic tiles, porcelain stoneware with a rough surface. For the manufacture of benches and wall decoration, only hardwood is used to reduce the release of resins into the atmosphere of the room.

Coniferous wood is not used for the manufacture of bathroom furniture, wall coverings, ceilings. Benches, benches and shelves are soaked in oil or combined with wax. Do not use varnishes and synthetic dyes, the fumes of which will be harmful to health in the heat.