Baths are very popular in Russia. If there is enough space for construction, a separate steam room with a gable roof type will be the best option.

- What should be the roof for a bath

- Material selection

- Thermal insulation

- Types of loads acting on the roof of the bath

- Snow load calculation

- Calculation of wind loads

- Amount of material

- Required tools

- Operating procedure

- Mauerlat installation

- Lathing

- Warming

- Features of fastening rafters on a round log bath

- Roof finishing tips

What should be the roof for a bath

The gable type is considered a popular roofing structure. It gives the building functionality and aesthetics. The roof involves the connection of a pair of planes located at an angle to each other. The frontal projection has the shape of an isosceles triangle.

The roof of the bathhouse with its own hands includes a frame made of rafters, which is a set of elements that support the roofing material. It includes a mauerlat, rafters, tightening, ridge girder, racks and struts. The device is made from high quality coniferous trees. The location calculation depends on the expected load. The rafters resist collapse and provide rigidity to the roof. Hanging and oblique types are usually used.

The roofing cake contains a layer of waterproofing, which is placed under the batten, located on the rafters. Roofing material, corrugated board, metal tile, ondulin or slate are more often used.

Material selection

The operation of the structure depends on the choice of material. The best are metal tiles and corrugated board with a polymer coating.

Ondulin is an excellent material with an organic base. The basis is made up of cellulose fibers impregnated with bitumen and polymer. Possesses a high degree of moisture resistance, but insufficient strength.

Thermal insulation

If there is a cold roof in the bath, you should take care of its insulation. Usually expanded clay or mineral wool is used.

Expanded clay has the shape of oval granules. The basis is clay. The material is resistant to fire and moisture. Possesses a high degree of sound insulation. Ecologicaly clean. Of the minuses, it should be noted increased moisture absorption. Therefore, waterproofing is additionally used.

Mineral wool is a versatile material. Lightweight and fire resistant. Differs in vapor permeability and strength. The disadvantages include increased moisture absorption. Experience is required when installing the material.

Types of loads acting on the roof of the bath

It is customary to allocate permanent or static loads exerted by the own weight of the coating. There are also snow and wind ones. Their indicators are taken into account when erecting a roof.

Snow load calculation

Usually the formula is applied Sα = S0 (60 ° - α) / (60 ° - 25 °)where Sα is an indicator of snow load for roofs with a slope from 0 ° to 25 °.

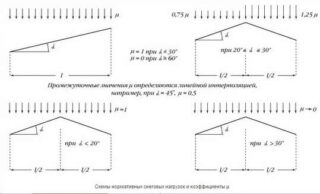

Calculation of wind loads

To calculate the wind load, denoted w (depends on the height of the roof above the ground z), one should rely on the formula Wр = Wk (z) c... In calculus W is a calculated indicator of wind pressure, k - a coefficient that takes into account changes in wind pressure, and from - an indicator of the change in the pressure of forces, depending on the location of the slope in relation to the leeward and windward sides.

Amount of material

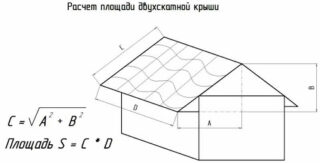

The correct calculation of a simple structure is not difficult. For this purpose, the appearance of the roof and the indicator of its area should be determined.

For example, the area of the main roof is 5.80 mx 2.81 mx 2 = 32.6 m², and the canopy above the entrance is 1.7 mx 0.9 m + 1.7 mx 0.4 m = 2.21 m². The total figure is 34.8 m². It allows the laying of 2m x 0.92m profiled galvanized steel sheets without waste.

Some sheets are cut in half. The total length of the covering along the roof rafters is 1 m + 2 m = 3 m. The overlap is 15–20 cm. In the final calculation of the roof area, the addition of the missing 10% overlap is taken into account: 34.8 m 2 + 3.5 m 2 = 38.3 m³ ...

Required tools

When building a building with your own hands, you should prepare:

- plane;

- hacksaw;

- grinder;

- electric drill;

- a hammer;

- screwdriver;

- scissors;

- sledgehammer;

- building level;

- chisel.

Measuring devices will also be needed. A tape measure and a plumb line should be prepared.

Operating procedure

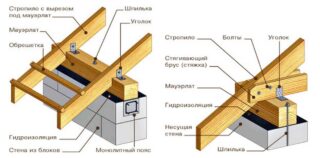

Mauerlat installation

With the help of anchors, waterproofing based on roofing material is attached to the wall, and on top of a wooden beam, in which holes are made for installing rafters. Mauerlat is horizontal. For a pitched structure, a rafter leg in the shape of a triangle is installed. The structure is fastened by means of metal corners so that the legs of the rafters enter the material compartments. To provide additional rigidity, special slopes are mounted. The joining points of the rafters in the corner from above are connected by means of twine. This is how the position of the skate is outlined. This is followed by the installation of rafters in increments of 1 meter or less. The indicator depends on the angle of inclination of the roof.

Lathing

After connecting the rafters, it is necessary to make a crate. The cross-section of the material and the size of the gaps depend on the type of roof. For the construction of a structure, a bar, boards or poles are used. For a soft roof, the sheathing is made on the basis of boards with a gap of 1 cm. For sheet material, the structure is erected from beams with a cross-sectional index of 5-50 cm.

The main steps in the process include:

- Laying waterproofing material.

- Material preparation. The bars should be smooth.

- Preparation of stairs and walkways for movement on the roof.

- Treatment of the sheathing beams with an antiseptic.

- Laying materials for the lathing.

They begin to build from the ridge in the direction from top to bottom. For this purpose, a ridge bar is nailed. First of all, the beams are attached, and then the boards, which are laid with the convex side down. This ensures that the water is drained. Wooden components are laid at the same distance from each other, taking into account the material for the roof. Galvanized steel is used to close the ridge.

The bars are attached to the frame with screws or nails. To protect against corrosion, the elements are coated with a special solution.

Self-production of the crate requires special skills and abilities. The construction of this part of the supporting structure is associated with the construction of rafters and a roof.

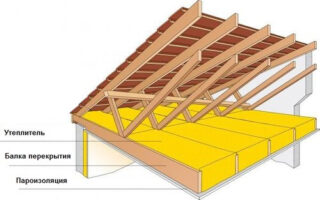

Warming

Usually 10 cm thick mineral wool is used. Initially, a vapor barrier material is laid on the rafters. It serves as a protection against moisture penetration from internal bath rooms. Then the insulation and the waterproofing layer are laid. Protective films are laid with an overlap of 15-20 cm, and then glued together with construction tape.

Features of fastening rafters on a round log bath

The main difficulty of fastening is fixing the lower part of the rafters. It is impossible to fix a flat board to a round log.The contact of elements at one point does not provide reliability.

There are two options for fixing: cuts in logs or mounting the roof on the ceiling beams. The second type is more durable. For its execution, marks are applied on the upper rim of the ceiling. It is recommended to resort to using a laser level.

All beams must lie horizontally and in the same plane. Cutting logs must not be carried out to a depth that exceeds one third of their diameter.

At the extreme marks, it is necessary to drive in nails and pull a rope between them. When marking the installation zones of the rafter legs, the level is attached to the rope, and the end rests on the frame. A horizontal line should be set and marked on the upper rim. The depth of the cut of the log is controlled by the marks applied.

The technology provides the arrangement of the beams in the same plane and in the horizontal direction.

Roof finishing tips

For roof sheathing, corrugated board or shingles are used. Fixation is carried out by means of self-tapping screws or thermal washers. Self-tapping screws are not recommended to be tightened too tightly, as the material should contract and expand depending on the temperature. The sheets are attached to one side with a longitudinal overlap. Initially, the first row is mounted, and then the initial sheet of the second.

The end is protected by a galvanized strip. Then the overhangs of the cornice and pediment are hemmed. Details are sheathed vertically or horizontally with an overlap covering the base of the rafters.