A common base for fencing a site is a strip foundation. A monolithic tape is poured under structures that are distinguished by significant weight and windage, for example, made of stone, brick, concrete, corrugated board. The owners of the plots make a strip foundation for the fence with their own hands in order to avoid overspending on the payment of specialists.

- Depth and width of the foundation depending on the weight of the fence

- Depth calculation

- Belt width

- Materials for the construction of strip foundations

- Selection of concrete grade and reinforcement diameter

- The main problems during construction

- Excavation

- Trench and crushed stone construction

- Formwork installation and reinforcement

- Concrete pouring process

- Concrete pouring and sinus backfilling

- How to eliminate air bubbles in concrete

- Solidification of the strip foundation

- Concrete maintenance and stripping

- Recommendations

Depth and width of the foundation depending on the weight of the fence

The first stage of construction begins with determining the size of the base, while taking into account the depth mark of freezing of the earth, the height of the rise of soil moisture during floods, and the type of soil.

The depth of freezing is important, since in winter the water in the soil turns into ice, expands, swells the upper layers together with the foundation. It is dangerous for the layers of the earth saturated with moisture, therefore, pay attention to the height of the standing water. Swelling of the soil depends on its type, for example, clay and clay soils are most susceptible to this phenomenon.

Depth calculation

It makes no sense to build a deep foundation if the mass of the fence is small, for example, the main weight is created by support pillars. For them, the depth is taken so that the sole is 10 cm below the freezing point.In some areas, it can be 1.2 - 1.7 m.

The main strip of the strip fence with pillars, the filling of which is made of sheet material, is deepened by 0.6 - 0.8 m, this is quite enough taking into account the weight of the spans sewing and the windage of the structure. For stone, brick massive concrete fences, the tape is deepened by 0.9 - 1.2 m.

Belt width

The parameter depends on the specific load on the base area, density and composition of the soil. Maximum loads per square of each type of soil are given in special tables of construction SNiPs.

The weight of each individual section of the fence is calculated, then the result is divided by the calculated indicator from the table. This gives the required base area. Divide the recommended square by the span length to find the width of the strip foundation.

Materials for the construction of strip foundations

More often, pouring a monolithic concrete tape with a built-in reinforcing cage is done. Such a foundation has acceptable performance characteristics. Rubble stone masonry is used less often due to the high cost of the material.

A brick foundation is made under the fence and gates, for which they take a red fired clay variety, since silicate stones absorb moisture. The foundation for the fence can be made from prefabricated prefabricated reinforced concrete blocks, which are connected by welding of embedded parts.

Selection of concrete grade and reinforcement diameter

For the base under the fence, it is recommended to use the concrete grade M 200 or M 300 in order to create sufficient strength to take the loads. Be sure to observe the proportions to prepare the concrete mixture: 1: 3: 5 (cement M 200, river sand, crushed stone, respectively).

For longitudinal strips, hot-rolled reinforcement of class A-III, A-II is taken, a bar A-I with a smooth wall is used for transversely arranged parts. The ribbed surface enhances adhesion to concrete. For reinforcement, a reinforcement with a diameter of 10 mm is prepared, the cross-section can be reduced if the weight of the fence is small.

The main problems during construction

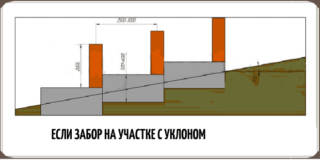

Before pouring the tape under the fence, you need to take into account the relief of the land plot. For construction on a slope, the tape is divided into separate sections that have different heights in relation to each other. A level is used for marking, corners and turns are marked with a theodolite.

Problems will appear if the characteristics of the soil have not been taken into account, its ability to heave. During construction, it is necessary to compact the base under the concrete band to avoid shearing during operation.

Excavation

Small trenches are dug by hand using a bayonet shovel and crowbar. The roots in the ground are cut with an ax. For a long foundation, a large amount of excavation will be required, therefore, a mechanized method using excavators is used.

In any case, the bottom of the pit is cleaned up to the design mark, the procedure is done manually. The height of the crushed stone and cement backfill is taken into account when calculating the depth of the trench in order to maintain the required dimensions of the concrete tape.

Trench and crushed stone construction

In the first case, a trench is dug in width so that it is possible to make a wooden formwork for concrete. The second option involves pouring the mixture directly into a trench, the width of which corresponds to the estimated size of the tape. Both options have a right to exist.

At the bottom, make a bed of sand (5 cm), crushed stone (10 cm). The rammed cushion reinforces the base under the sole and increases its density. Serves as a drainage for the removal of groundwater, prevents the shift and heaving of the soil.

Formwork installation and reinforcement

The frame is made of boards or sheets of chip-pressed material. Fencing elements are connected with bars, slats, fastened with nuts, nails, pins. The boards are supported with bars from the outside, the top is also connected with slats so that the formwork does not disperse under the weight of concrete.

Reinforcement increases the punching and bending strength of the foundation. The rods are laid longitudinally, after 0.5 - 0.7 m, jumpers from the rod are placed. The elements are welded together or tied with wire.

Concrete pouring process

Before concreting, at a level of 20-30 cm from the foot of the future foundation, a drainage pipe with a slope is placed, which is taken out into the storm sewer collector. The concrete for pouring is prepared independently in concrete mixers. The manual method of kneading on a sheet of metal or in a trough is no longer used.

Ready-made mixtures can be ordered from specialized organizations. It is brought in car mixers, while mixing is continuous, even while moving to the object. This method is convenient, but it costs about twice as much.

Concrete pouring and sinus backfilling

It is advisable to concrete the entire foundation in one day. If this is not possible, the connecting seam is made at a slope, like a "escape groove".

Step-by-step instructions for making a strip foundation for a do-it-yourself fence:

- removing concrete from a concrete mixer into a bucket;

- pouring mass into the formwork;

- distribution of mortar between reinforcement using a trowel, shovel.

Backfilling of the earth is performed after removing the formwork. To do this, use the excavated soil or take sand, clay. When laying the sinuses, the material is compacted with rammers, but they do it carefully, since the concrete has not yet gained 100% strength.

How to eliminate air bubbles in concrete

Air accumulations weaken the strength of the concrete mix.Bubble cavities are open and closed, moisture enters them and affects the process of concrete hardening. As the pouring proceeds, the mass is compacted and the bubbles are distilled out regularly.

There are sealing methods:

- vibration;

- rammer;

- bayonet.

An electric deep vibrator works best. If it is not there, it is compacted with a shovel, steel bar. The rammer is used for heavily loaded bases.

Solidification of the strip foundation

The mixture grasps in a day, but gains the required strength on the 28th day after pouring. Such indicators are typical for an average air temperature of + 20 ° С. If concreting takes place at temperatures from + 5 ° C to + 15 ° C, the strength gain is stretched for one and a half to two months.

On frosty days, the moisture in the composition of the material freezes, so the set of strength stops. In winter, it is correct to make a tape under the fence with heating the mass with electricity to prevent freezing.

Concrete maintenance and stripping

The surface of the laid mixture is leveled with a trowel or spatula. A plastic wrap is laid on the area to protect the material from moisture loss. Another method involves covering the surface of the foundation with sawdust or shavings with a layer of about 3 cm. Wood waste is watered 1-2 times a day.

The formwork is removed 7-10 days after pouring, provided that the air temperature is more than + 10 ° C. Previously, it is not worth removing the boards, it is better to create conditions for normal concrete maturation.

Recommendations

After the foundation is installed, it is covered with a layer of roofing material so that moisture is not transferred to the structure of pillars, brick or masonry. When concreting metal supports, their lower part is coated with resin, wrapped in two layers of roofing tar paper or roofing material to prevent rust.

The formwork is placed so that the reinforcement does not reach the walls of the foundation by 5 cm. Reducing the gap will lead to corrosion of the frame inside the base. Failure to use reinforcement will result in deflection of the foundation under load.