The entrance to the garage provides convenient parking and smoothing of the plane in front of the gate. In addition, the ramp allows you to protect the interior of the room from precipitation.

How to make a check into the garage with your own hands

It is recommended to start construction of the entrance after preliminary study of the necessary information. It is important to consider additional factors such as ride length and grade. The main task is to create the most convenient way for arrival. The design should exclude sharp rises in height. The height of the floor in the garage also plays an important role.

It is recommended to choose the optimal size of the entrance. The most efficient and cheapest is the straight construction, which is 30 cm wider than the gate. This entry is convenient.

For a high-quality construction, regardless of the design features of the garage, the dimensions of the ramp should be calculated. For this purpose, a large-scale scheme is drawn up, which makes it possible to determine the required amount of materials.

It is important to consider:

- the height of the curb, which serves to prevent the vehicle from leaving the elevation;

- water drainage system;

- organization of a smooth congress;

- equipping the entrance with a visor.

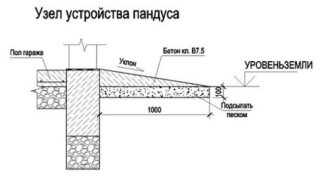

To ensure the smoothness of the height difference between the ground level and the threshold, the selection of the optimal ramp length is required. If the road is not level with the garage floor, it is recommended to build a slight incline to avoid water ingress.

The length depends on specific conditions. The optimal slope is 5 meters. The entrance often has the shape of a trapezoid, where the smaller end is located at the gate. The recommended draft angle is 6 to 25 degrees.

Material for construction

Do-it-yourself entry is within the power of every car owner. An important part of the process is the correct choice of material and maximum adherence to technology. The device can be made on the basis of concrete, metal, wood or paving slabs.

The metal structure is inherent in strength and reliability, but icing in the winter makes its surface slippery. The wood device is simple, but needs to be replaced every 3 years.

The site, lined with paving slabs, looks attractive and serves for a long time. Of the minuses, it should be noted the tendency to icing and low resistance to salt. The best way is to drive into a concrete garage. It is an inexpensive and high-strength material with high performance characteristics.

Preparatory work

The area in front of the garage needs marking. It is performed by means of wooden or metal pegs, which are connected along the contour by means of a rope. It is marked with flags.

The next step is to dig a pit. To ensure the long-term operation of the ramp, it is necessary to pour concrete to a greater depth than the level of soil freezing in the area. The bottom is covered with rubble. The layer thickness should be 10 cm. The material is leveled and compacted. Crushed stone is covered with a layer of sand, which is watered abundantly with water and also compacted.

The basis of the formwork is a wooden board or slate.The latter material is preferable because it forms a monolith with concrete and protects it from destruction. Slate can also be used for small curbs. After the construction of the formwork, the ramp is poured with concrete

After the concrete mixture has hardened, trenches are prepared for the curb. It can be installed on a foundation or on a cushion of sand and gravel. The race must be allowed to dry for 28 days.

Concreting the structure

The entrance to the garage made of concrete is considered the most optimal. Its construction is laborious. The design requires money.

The following materials are required:

- cement grade not lower than M400;

- medium fraction gravel;

- sand;

- lumber for the installation of formwork;

- various additives to concrete to increase the level of resistance to frost and moisture;

- fittings with a cross-sectional index of 6-8mm;

- concrete mixer;

- shovel and bayonet shovel;

- buckets.

To prepare the solution, cement and sand are taken. The components are mixed in a 1: 3 ratio. Gravel or crushed stone is used as a filler.

The entrance to the garage with a rise is mounted in the following sequence:

- Clearing the site for the structure from debris and stones.

- Exclusion of the presence of underground utilities.

- Drawing up a drawing indicating the required dimensions. The optimal ramp slope is 15%.

- Formation of the required soil slope. To accomplish the task, the hydro level is used.

- Compaction of the top layer of soil by means of a vibrating saw.

- Soil shrinkage and re-compaction of the layer.

- Formwork installation.

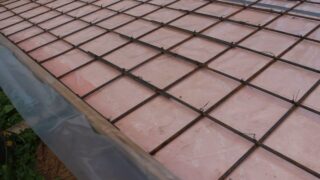

- Installation of a reinforcing frame. The rods are welded or tied in the form of a grid with cells of 25-30 cm.

The concrete is poured in layers. Each batch is leveled. When working in warm weather, the layers are covered with polyethylene. In hot weather, it is recommended to water the site with water.

When pouring concrete, it is necessary to remove air from the mixture. For this purpose, a reinforcing bar is used, which pierces the mass. If this rule is not followed, voids are formed inside the ramp, which reduces the level of its strength.

Additional recommendations

The ramp is provided with a drainage system. A special groove is formed in front of the threshold. It serves as a drain for water. The structure is closed with a grating that ensures the drainage of atmospheric precipitation.

In parallel with the ramp on the side of the garage floor, a special ramp is constructed - a counter-ramp, so that you can drive in smoothly and reduce the load on the car suspension.

In some cases, a special canopy is installed over the structure, which protects it from snow and rain.