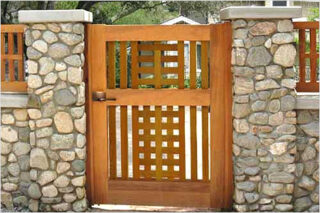

A wooden gate is a popular option for making a passage in the fence of a site, since wood has a natural appeal, it is combined with a metal and forged fence, structures made of corrugated board. They draw up a drawing, choose a configuration, acquire accessories to make a wooden gate with their own hands. The material of the support pillars is wood, metal and asbestos-cement pipes, brick and concrete pillars.

Advantages and disadvantages of a wooden wicket

The material is inexpensive, it is not difficult to purchase it when it comes to common types of wood. Expensive breeds are rarely used, mainly conifers are used.

Advantages of a wicket for a fence made of wood:

- low weight of the structure, reliability and strength;

- fast manufacturing, easy assembly and processing;

- environmental safety for human health;

- lack of sophisticated equipment during manufacturing.

The disadvantages include the fragility of wood in comparison with other materials, since it intensively absorbs water. As a result, the structure rots, microorganisms multiply on the surface and inside. Bugs violate the integrity of the fibers, weaken the strength.

Without protective impregnation, the product will last 5 - 7 years. The tree ignites quickly, does not stop burning on its own, so it needs to be treated with drugs to increase fire resistance.

Variety of designs

The structure of the wicket includes support posts, a canvas in a frame. The sash is fixed to the pillars using hinges that open in one direction or swing open in two directions (pendulum awnings). The framing of the door is made of wood, welded from an iron corner.

They open the gate manually, sometimes they turn on the automation and operate the remote control. More often, the sash is made with a swing, but roll-back opening is allowed, then a metal frame with a wooden filling inside is necessarily used.

Varieties of schemes of wooden gates for a private house:

- slatted canvases made of sparse picket fence;

- solid doors, if the boards are placed close to each other, without a gap;

- doors made with openwork wood carvings in antique or modern style;

- structures with a wooden frame of an arched or lancet shape;

- passages with canopies in the form of a gable wooden roof;

- built-in passages in the door leaf.

Wooden wickets with arched doors never go out of style. Sometimes the arch is placed in the form of a vault over the passage.

How to choose lumber

Different breeds differ in terms of strength, moisture resistance, durability. On the cut, each variety has its own unique pattern. Plot owners choose material according to properties and characteristics, take into account their material capabilities.

Briefly about the breeds:

- Oak hardly swells and does not dry out when humidity changes. Decent high density material that is difficult to handle is expensive.

- Larch firmly resists moisture and rot. It is characterized by a beautiful grain pattern, it is easy to saw.

- Pine is notable for its low cost, low strength.Contains resinous components and absorbs little water.

- Spruce is classified as a soft species; upon contact with the soil, it begins to rot. The wood is durable and inexpensive, therefore it is used after preliminary impregnation.

In addition to the species, the quality of the wood is taken into account. Boards should not have curvatures, rotten and falling out knots, cracks along the length and across the lumber.

Fittings for wickets

A wooden fence gate functions with canopies, handles, locks, latches. For work in outdoor conditions, accessories with a galvanized coating, stainless steel, thick aluminum are purchased.

Recommended items:

- Awnings can be classic, decorative or hidden.

- Locks are used overhead, mortise or hinged. For wooden structures, electronic and electrical locks are rarely, but sometimes used.

- The handles are made of iron, made of wood, forged look good. The staples are placed as a separate element or combined with a locking mechanism.

- The latches are placed on the inner surface of the canvas in order to close the gate without a key while staying at home.

For a gate in a fence of a vegetable garden or garden area, they put simple fittings without frills. The entrance group on the site is equipped with more stylish elements, which are selected according to the type of details of the gate, fence.

Required tools and materials

For pillars, a beam of 100 x 100 mm is taken, while it is hidden under the ground by 60 - 100 cm. The height of the support is calculated so as to take into account the depth and height of the fence and wicket. A 40 x 40 mm bar is used for the frame. The canvas is sheathed with a picket fence, a 40 x 20 mm rail, and a 20 x 100 - 150 mm board is placed. Materials for concrete mix are prepared (sand, crushed stone, cement).

DIY tools for making wickets from boards:

- carpentry square, tape measure 5 m, level, pencil;

- a hacksaw for wood or an electric jigsaw;

- screwdriver, Phillips screwdriver;

- sandpaper.

If you are using rough sawn timber, you will need an electric or manual planer. For excavation work, you need a bayonet shovel, scrap, the installation of pillars is coordinated with a plumb line.

Manufacturing procedure

Step-by-step distribution of work:

- installation of supports;

- assembly of the gate frame;

- door sewing;

- hinged;

- installation of constipation;

- final finishing.

Preliminary design will help to correctly calculate the amount of material, the number of hardware, and determine the order of assembly. The sketch will visually show the appearance, so you can make changes to the circuit in a timely manner.

Installation of pillars

They dig a hole, which is 10 cm wider than the support on each side. A narrow pit will not allow high-quality pouring and distribution of concrete. At the bottom, make a pillow of 5 cm of sand and 10 cm of rubble. The layers are rammed simultaneously with watering to shrink.

The underground part of the wooden bar is covered with hot (60 °) linseed oil, wrapped with a layer of roofing material or two layers of building roofing so that it comes out from the ground by 5 - 7 cm. This is necessary for waterproofing the column so that it does not start to rot from soil moisture and rain.

Metal rods are drilled into the body of the underground part so that they protrude 5-10 cm on the sides. They are concreted in bulk and receive an additional support against loosening over time. The concrete is poured into the pit after the support is in the mounting position. They use bayonetting of the mass with a shovel, metal pins, to expel air bubbles.

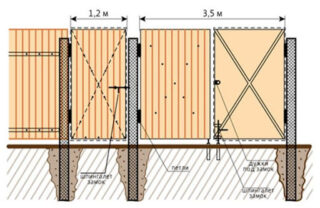

Correct installation of the wicket

A gate made of a terrace board, rail, picket fence is made so that a person of any size can freely pass through it, carry hand luggage on a trolley. The standard dimensions of the opening in width are 1 - 1.2 meters.

If a fence with a wicket is located so that the canvas swings open onto the sidewalk or roadway, an internal opening is designed so as not to interfere with passing people and cyclists.

Under the canvas at the bottom, a gap is provided above the ground with a height of 10 - 15 cm. This solution helps with snow drifts, so that you can open the door without cleaning the snow. Hinges and locks are positioned so that they cannot be damaged from the street.

Assembly of the structure and cladding

The frame is assembled along the width of the span by 10 mm, to take into account the free passage of the canvas. They use pretended wooden planks so that there is no gap when viewed from the street.

Operating procedure:

- fasten the sidewalls, upper and lower frame strips, use an additional crossbar and diagonals for rigidity;

- cutting elements of filling from boards or strips in such an amount as to obtain a continuous lining;

- to attach the elements at each point, 2 nails or self-tapping screws are placed;

- the lower parts of the canopies are fixed on the pillars, checking the verticality with a level;

- the upper parts of the hinges are fixed on the door frame, the canvas is hung on the supports.

The final finishing is done after checking the correct opening.

Painting the finished gate

Before painting, wooden parts are impregnated with antiseptics with anti-fire preparations, then primed. The compositions are selected in accordance with the type of paintwork.

Varieties of wood paints:

- Acrylic or latex. They dry quickly, do not smell, create a strong protective film, but are expensive.

- Stains. They do not paint over, but emphasize the texture, the film does not form, the tree breathes. Requires additional varnishing.

- Oil formulations. They form a dense layer that is impervious to moisture. It smells harsh, but the smell disappears after it dries completely.

For a primer before oil paint, varnish, solvent-based primers, white spirit are used. Water-based formulations are used for water-based emulsion.

A Few Tips

Resin appears on the surface of coniferous wood, which ultimately spoils the quality of the painting. Before finishing the surface of the boards, the bars are wiped with solvents (acetone, gasoline, soda ash solution, alcohol).

After applying the first layer of varnish on fresh wood, fine fibers and pile rise on the surface, therefore additional sanding of the canvas is required. This does not happen after the second varnishing.

The paint is applied in 2 - 3 layers to protect the material from destruction and obtain an even layer. Before processing, you can putty and repair cracks, chips, knot holes.