The indoor pool at the dacha is a complex hydrotechnical complex, including a bowl, a drainage system, filtration and water supply. It can be additionally equipped with lighting and heating equipment. It will not be superfluous to equip an artificial reservoir with a roof that protects the water mirror from falling leaves, and the pool itself from dust, insects and other contaminants entering and accumulating at the bottom.

Pool types

Indoor swimming pools are of three types:

- stationary;

- collapsible (frame);

- inflatable.

Stationary pools are permanent structures, the bowl for which can be made of plastic or concrete. They are installed in a pre-dug pit, for which a preliminary study of the soil is carried out. You can purchase and install a factory-made bowl (plastic, composite material, polypropylene) or cast it yourself from concrete. The presence of a roof or a special pavilion will significantly improve the operational characteristics of such a pool.

Collapsible structures can reach stationary dimensions, however, they are not deepened into the ground, but installed on a flat platform. As a rule, tent tents are installed over pools of this type, although stationary structures are sometimes found.

Inflatable options are comparable in size to small frame pools and do not exceed one and a half meters in diameter. They are installed under the sheds available on the territory of the summer cottage, and models with inflatable roofs are purchased for children.

Materials for the manufacture of roofing

As a material for the roof of the pool, you can use:

- Aluminum is durable and at the same time lightweight, does not corrode and does not require complex maintenance. It is used in the production of profiled frames of various sizes.

- Steel - used to make large simple frames. Steel fixed frames are made of pipes and profiled metal. Steel corrodes when exposed to moisture, therefore, structures made of it must be painted.

- Wood - used to make frames of complex shapes. Wooden structures made of wood require protection from moisture. They can be both stationary and mobile.

- Glass - used in the manufacture of large stationary awnings without bent elements. It is recommended to use impact-resistant glass grades.

- Polycarbonate is a high impact polymer material that comes in smooth and honeycomb types. The first resembles glass and has increased strength. Due to incomplete transparency, polycarbonate protects well from direct sunlight. Differs in a large variety of colors.

- Foil materials are a popular material for large-area roofing. However, the film is easily damaged by sharp objects and hail.

- Awning fabric is a durable material with a wide range of colors. Does not let light through.

Most often, awnings and awnings are purchased ready-made or made independently.

Indoor pool design

Getting started with the idea of building your own indoor pool, first of all, you need to develop a project. It takes into account all the technical features of a hydraulic structure.

In the absence of experience in designing complex objects, it is best to entrust the development of an indoor pool project for a country house to a specialized organization.

The design process includes a definition:

- type of construction;

- the size and shape of the future structure;

- pool depth;

- list of required materials;

- the type and design of the pavilion or other type of protective canopy;

- selection of equipment for creating a comfortable microclimate inside the pavilion.

The issue of auxiliary equipment is also being resolved, which includes systems for supplying and removing water, as well as its heating.

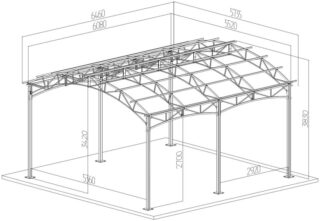

After the tasks are solved, they begin to design a canopy or pavilion. At this stage, drawings are developed, which display the shape of the shelter, all its dimensions and a list of required materials.

For comfortable use of an indoor pool, it is necessary to constantly monitor and maintain a temperature of + 23 ... 25 ° C and a humidity of no more than 50%.

If it is impossible to use profiled materials for the manufacture of the frame, it is advisable to use steel pipes - this will make it possible to make a strong frame. If it is possible to use a pipe bending device, the steel elements can be shaped to any shape.

Strength calculations are always carried out with a margin, which will ensure the reliability of the structure even in unforeseen situations, for example, with heavy snowfalls.

The roof over the indoor pool in the country, as a rule, is made inclined. This will allow the adhering snow to slide off on its own. If the canopy is designed as a semi-open one, it is necessary to provide for the presence of additional awnings that will close the pool in winter.

The development of the project ends with the preparation of an estimate, as well as the determination of the phased and total cost of construction.

Selection and preparation of a place for a pool

An artificial reservoir should be installed on a flat surface, and therefore it is recommended to make sure that there is no slope using a level.

Pools are installed on smooth ground or on a specially prepared area, primarily for frame or inflatable models. For stationary reservoirs, the bottom of the excavated pit must be flat.

Frame pool

It is not difficult to prepare the site and install the collapsible structure of the pool:

- Use wooden pegs to mark the boundaries of the pool base. In this case, it is recommended to add to it from 15 to 30 cm of stock.

- Measure the angle of inclination of the surface of the site. If the slope of the latter exceeds 5 cm by one meter, the platform must be leveled.

- Clear the installation site from foreign objects, plants.

- Lay a mat on the PVC site. Often the latter is included in the pool kit, but if it is not there, you will have to purchase it.

The pool is assembled and installed in a prepared place, after which it is filled with water. If necessary, proceed to the installation of the awning or tent.

Stationary pool

Preparing a place for a concrete or polymer bowl of a stationary pool is much more difficult than for a frame one. This process is reduced to digging a pit according to the dimensions specified by the project.

The territory of the site is marked with wooden pegs, between which a cord is pulled, clearly showing the configuration of the bowl. In this case, the dimensions of the pit should be somewhat larger than the dimensions of the latter.

They dig a pit with the involvement of special construction equipment to the required depth, begin to prepare its bottom.

When building a concrete bowl, it is recommended to give the bottom a slight slope and lay a pipe for draining water at its lowest point, be sure to take it out of the pit.

The bottom of the pit is covered in layers with a 30-centimeter layer of sand and a 10-centimeter layer of rubble.Each layer is carefully compacted.

Depending on the type of bowl, the following operations are performed:

- Before installing the polymer bowl, a metal mesh is laid on the bottom, over which 25 centimeters of concrete is poured. After the concrete hardens, geotextiles are laid on the bottom, and then expanded polystyrene plates with a thickness of at least 3 cm are laid - in this way the bottom of the bowl is isolated from the ground. The bowl itself is insulated with expanded polystyrene from the outside before it is installed in the pit.

- To pour a concrete bowl, the bottom and walls of the pit are reinforced, and then the formwork is installed.

At this stage, you need to install all the auxiliary equipment, since after pouring the frame of the bowl with concrete, it will be impossible to install it.

Pool construction and finishing

Indoor pool construction is carried out in two ways:

- Installing a plastic bowl into the prepared pit and pouring concrete into the voids between their walls. In this case, the walls of the bowl must be reinforced from the inside with special spacers, which will protect them from deformation.

- Pouring a concrete bowl according to a typical process. Here it is important to fill the bottom and walls in one step.

Finishing the inner surface of the plastic bowl is not required, therefore, after the poured concrete has completely hardened and gains the necessary strength, the pool can be used.

The surface of the concrete bowl will require finishing and decoration. For this purpose, use:

- Multi-colored PVC films, which, in addition to decorating, will also perform a waterproofing function.

- Polypropylene with high strength and resistance to aggressive environments. For decoration, a blue or light blue material with a glossy surface is often used. This is due to the fact that polypropylene sheets weld well.

- Glass mosaic with a minimum level of water absorption. Thanks to the original overflow of light, the material will give the pool a presentable look.

The construction of a stationary pavilion will require the laying of a shallow strip foundation. When installing awning shelters, you can use small columnar "pyataks" made of concrete. They are mounted in small depressions, half filled with a gravel-sand mixture.